Pet Food Manufacturing Cost Analysis: Crunching the Numbers

What is Pet Food?

Pet foods consist of commercially processed foods that contain nutritional requirements tailored according to their consumption by domesticated pets like dogs, cats, birds, fish, and small animals. The foods contain planned nutritional compositions, such as ingredients like protein, carbohydrate, fat, vitamins, and minerals. The processing is carried out under controlled conditions to form a processed meat that is safe for consumption and highly nutritious for pets. The foods come in various types, such as dry foods, wet foods, semi-moist foods, frozen foods, and fresh foods, which are usually intended for feeding purposes and taken on a daily basis for pets.

Key Applications Across Industries:

The primary use of pet food is nutritional, intended to ensure complete and balanced nutrition for pet animals. At the domestic level, pet food is considered the principal dietary component for dogs and cats, taking the place of home-cooked nutritionally balanced diets. The dry pet food product finds extensive usage as pet food based on its convenience, stability, and dental health benefits. The wet pet food is applied for its benefits related to hydration, palatability, and nutritional variety.

Specialized pet foods can cater to specified life stages like puppies, kittens, adults, and seniors. Functional pet foods can be used to treat certain health issues such as digestive sensitivity, weight management, joint health, skincare and coat care, kidney health, and food allergies. These kinds of pet foods can be prescribed by pet care practitioners and found in both home and hospital settings.

Pet food is also utilized for breeding kennels, shelters, boarding kennels, veterinary hospitals, as well as dog training centers, where dog food with a controlled and predictable nutritional content can play an important role. Snacks and treats, though considered supplementary to dog food, have a great role in dog training as well as building dog and owner attachment. Further, specialty or lifestyle pet foods like grain-free, high protein, organic, or raw diets have become popular with pet owners as a method of providing dogs with tailored dog food.

What the Expert Says: Market Overview & Growth Drivers

The global pet food market reached a value of USD 136.6 Billion in 2025. According to IMARC Group, the market is projected to reach USD 197.5 Billion by 2034, at a projected CAGR of 4.20% during 2026-2034. The pet food market is influenced by the pet population growth, the humanization of pets, and an understanding of animal nutrition. One of the most important drivers in the pet food market is the increased understanding of pets becoming part of the family rather than just an object. Such an understanding triggers pet owners to spend money on better-quality pet foods that meet the same nutritional standards expected in the human food market.

An increased urbanization rate, as well as changes in lifestyles, accelerates the development of this market. As many households embrace the busy, urban lifestyles, there will even be greater reliance on convenient, ready-to-serve pet foods. Commercial pet foods are convenient, are healthier, and are easier to store compared to homemade pet foods. An increased rate of lone-person households, as well as an aging population, accelerates pet adoption even in urban areas.

Awareness regarding health and wellness amongst pet owners is another major driving force for the market. With easy availability of veterinary consulting, knowledge, and pet health information, the demand for specialty and preventive pet foods has risen substantially. Functional pet foods for digestion, immunity, weight, and aging are becoming popular all over the world. Trends for premiumization will promote differentiation based on sourcing and the formulation sciences of products.

The extension of distribution networks also assumes significance. The developments in organized retail, online platforms, and direct-to-consumer pet food brands make it easier for people to access goods. Online customization also fuels demand.

Finally, innovation in protein sources, processing methods, and sustainable approaches provides a foundation for the long-term growth of the market. Alternative proteins, safety protocols, and green approaches fit well within the emerging values of the modern pet owner. Overall, a combination of demographics, pet humanization, a growing interest in health, convenience demands, and innovation fuel the continuous expansion of the pet food processing industry throughout the world.

Case Study on Cost Model of Pet Food Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale pet food manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed pet food manufacturing plant in India. This plant is designed to manufacture 4,000 tons of pet food annually.

Manufacturing Process: The manufacturing process of pet food products is an elaborate process involving various stages managed in such a way as to ensure the correct nutritional content, suitability, and consistency of the food products. The entire process commences with procuring raw materials like animal protein, grains, vegetables, fat, vitamins, mineral components, and functional ingredients. These raw materials are tested before they are utilized in the manufacturing process of pet food products. After this, the ingredients are measured precisely before they are ground so as to have equal particle size. These are then blended using precise formulas for different species, life stages, or health requirements. In making dry pet food, for instance, the compounded dough undergoes an extrusion process in which it undergoes cooking under high temperature and pressure to gelatinize its starches, denature its proteins, and kill pathogenic bacteria. It can then be shaped in the form of kibbles by cutting it into desired sizes. Finally, it undergoes drying to remove its high levels of moisture. Fats, palatables, and flavor enhancers can then be applied using the coating method. Wet pet food has a separate process, as it is ground and cooked to a slurry, then put into a can/pouch and retorted to make it sterile. Fresh and frozen pet food is prepared by lower cooking methods or low processing, then cooled or frozen. The packaged dog and cat meals are to be stored under airtight conditions to maintain freshness. All through the processing of manufactured foods, quality control is done for monitoring the level of nutrients, moisture, textures, and microbiological quality. Processed foods are then packed and stored according to appropriate conditions. Emphasis is placed on automation, traceability, and strict regulation for maintaining quality.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

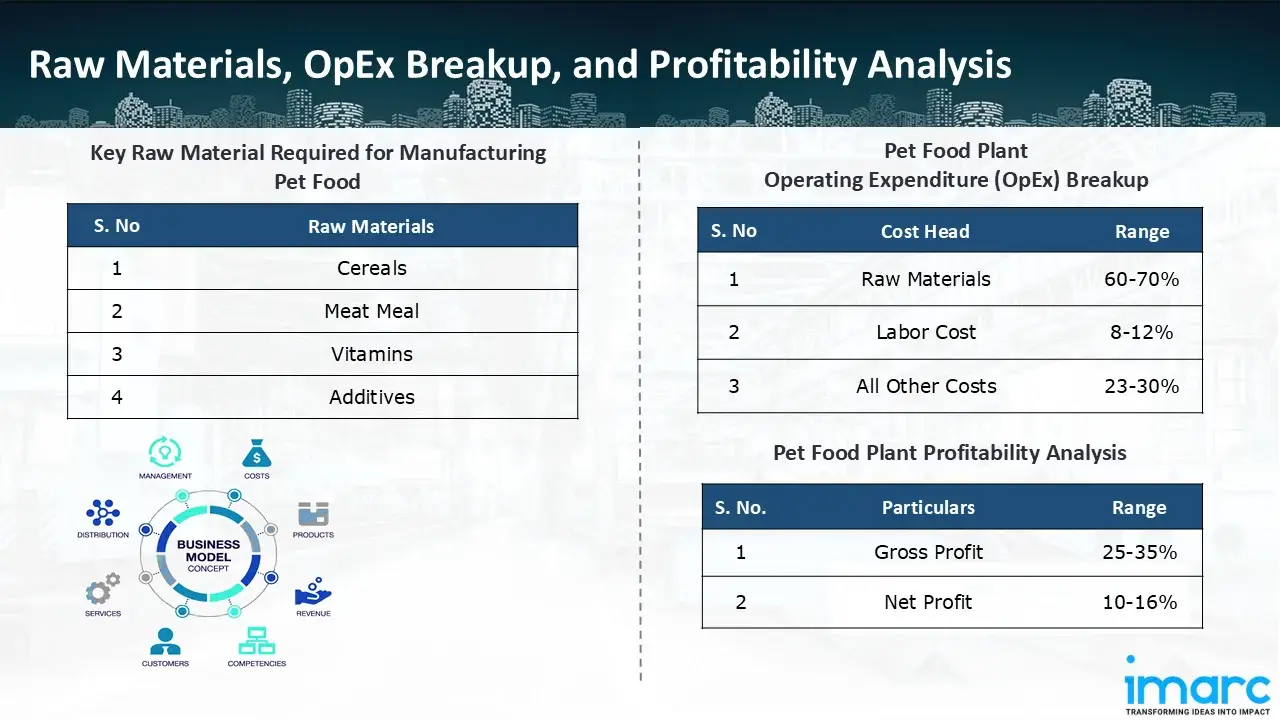

The basic raw materials required for pet food manufacturing include:

- Cereals

- Meat Meal

- Vitamins

- Additives

Machine Section or Lines Required:

- Grinding

- Mixing

- Extrusion

- Drying

- Coating

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in pet food manufacturing plant ranges between 60-70%, labor cost ranges between 8% to 12%, and all other costs ranges between 23-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-35%, and net profit lie between the range of 10-16% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the pet food manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 4,000 tons of pet food annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In August 2025, Snif-Snax, a Miami-based distributor and retailer that specialises in smoked Scottish salmon and chicken pet treats, was purchased by Firelight Capital Partners.

- In July 2025, Mars, Incorporated, a global leader that produces over 40 popular snacking, food, and pet brands in the US, such as Royal Canin®, M&M'S®, SNICKERS®, Ben's OriginalTM, PEDIGREE®, and SHEBA®, announced its plans to expand its U.S.-based manufacturing by investing an estimated US$ 2 Billion in its operations nationwide by the end of 2026.

- In June 2025, General Mills announced two new launches within its North America Pet sector with initiatives from Blue Buffalo and Edgard & Cooper. These initiatives are intended to address changing pet parent preferences and expedite the company's growth in pet feeding.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104