Ammonium Bicarbonate Cost Model: Comprehensive Profitability Analysis

What is Ammonium Bicarbonate?

Ammonium Bicarbonate (NH4HCO3) is a white crystalline inorganic chemical used extensively in the fertilizer, food processing, pharmaceutical, and chemical industries. It is a salt that is produced by the combination of ammonia, carbon dioxide, and water and is renowned for decomposing at relatively low temperatures into ammonia, carbon dioxide, and water vapor.

Key Applications Across Industries:

This characteristic makes it useful as a leavening agent for the food industry, especially in baked foods, cookies, and crackers, which produce a light and porous texture due to its presence. As a nitrogen fertilizer, ammonium bicarbonate is used in agriculture to supply crops with a source of available nitrogen. The compound is also employed as an intermediate in the production of ceramics, dyes, and flame retardants and in applications of pH control and buffering. Ammonium bicarbonate is mainly manufactured by gas–liquid reaction process from ammonia, carbon dioxide, and water. High solubility in water and biodegradability of the product make it a good environmental option over synthetic counterparts. Nonetheless, its heat instability restricts it for use in some applications that demand high-temperature processing. The material is extremely sensitive to humidity and heat and needs to be properly packaged and stored to remain stable. The market for ammonium bicarbonate globally is controlled by producers in China, India, and Southeast Asia due to the availability of feedstock and high agriculture demand. With increased focus on environmentally friendly fertilizer processes and green food additives, ammonium bicarbonate still remains a vital product in various end-use sectors.

What the Expert Says: Market Overview & Growth Drivers

The global ammonium bicarbonate market reached a value of USD 1.28 Billion in 2024. According to IMARC Group, the market is projected to reach USD 2.24 Billion by 2033, at a projected CAGR of 5.8% during 2025-2033. The international market for ammonium bicarbonate is mainly boosted by expanding demand within the food and agriculture industries. Ammonium bicarbonate is still an affordable and effective nitrogen fertilizer in agriculture, aiding crop yield enhancement in developing countries like China, India, and Indonesia.

As population pressures increase with the necessity for greater agricultural productivity, nitrogen-based fertilizers' consumption keeps increasing. Moreover, ammonium bicarbonate's use in organic and environmental agriculture is compatible with the world's move towards sustainable agricultural methods, yet another factor driving market demand higher. The food processing sector is another major industry driving growth, where ammonium bicarbonate is used widely as a leavening agent as well as pH controller in baked goods and confectionary items. Increase in global demand for packaged and processed foods, particularly in urbanizing areas, drives steady expansion in this category. Additionally, the use of the compound as a chemical manufacturing ingredient, such as dyes, pigments, and flame retardants, increases its utility in industry. From the production side, improvements in low-emission and closed-loop manufacturing technologies have enhanced performance and environment, which is prompting manufacturers to increase capacity. The low-priced availability of raw materials, carbon dioxide and ammonia, in the Asia-Pacific region is also enhancing market competitiveness. Moreover, the transition towards eco-friendly fertilizers and increasing government programs for carbon emission reduction are driving market uptake. Nevertheless, price volatility in ammonia and the product's short shelf life in high-temperature conditions are minor drawbacks. Overall, the ammonium bicarbonate market is expected to witness steady growth, driven by agricultural expansion, food industry growth, and sustainability-driven innovation.

Case Study on Cost Model of Ammonium Bicarbonate Manufacturing Plant

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale ammonium bicarbonate manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ammonium bicarbonate manufacturing plant in India. This plant is designed to produce 2,500 tons of ammonium bicarbonate annually.

Manufacturing Process: The production process of Ammonium Bicarbonate (NH4HCO3) consists of a gas–liquid reaction between ammonia gas (NH3), carbon dioxide (CO2), and water (H2O) in controlled temperature and pressure conditions. The process starts with the purification of raw material where ammonia and carbon dioxide are obtained from industrial by-product or chemical synthesis plant. These gases are cleaned to eliminate the impurities like sulfur compounds and moisture in order to achieve a high-purity final product. In the absorption process, ammonia gas purified is dissolved in water to create an aqueous ammonia solution. The solution is bubbled with carbon dioxide in a carbonation tower or a reactor, where dissolved ammonia and water react with the carbon dioxide to produce ammonium bicarbonate according to the reaction:

NH3 + CO2 + H2O → NH4HCO3.

The process is exothermic and is conducted at temperatures usually between 20°C and 40°C to ensure that ammonium bicarbonate precipitates as crystals. The reactor slurry is subsequently passed on to a crystallization unit, where crystals of ammonium bicarbonate are separated from the mother liquor via filtration or centrifugation. The crystals are washed to separate any remaining impurities and dried under vacuum or low-temperature air dryers to avoid decomposition. Lastly, the anhydrous ammonium bicarbonate is filtered and packed in impermeable bags, as the compound is extremely sensitive to heat and moisture. Most modern factories use closed-loop systems to recover unreacted ammonia and CO2 to enhance efficiency and minimize environmental emissions. The process produces high-purity ammonium bicarbonate for food-grade and industrial use.

Get a Tailored Feasibility Report for Your Project Request Sample

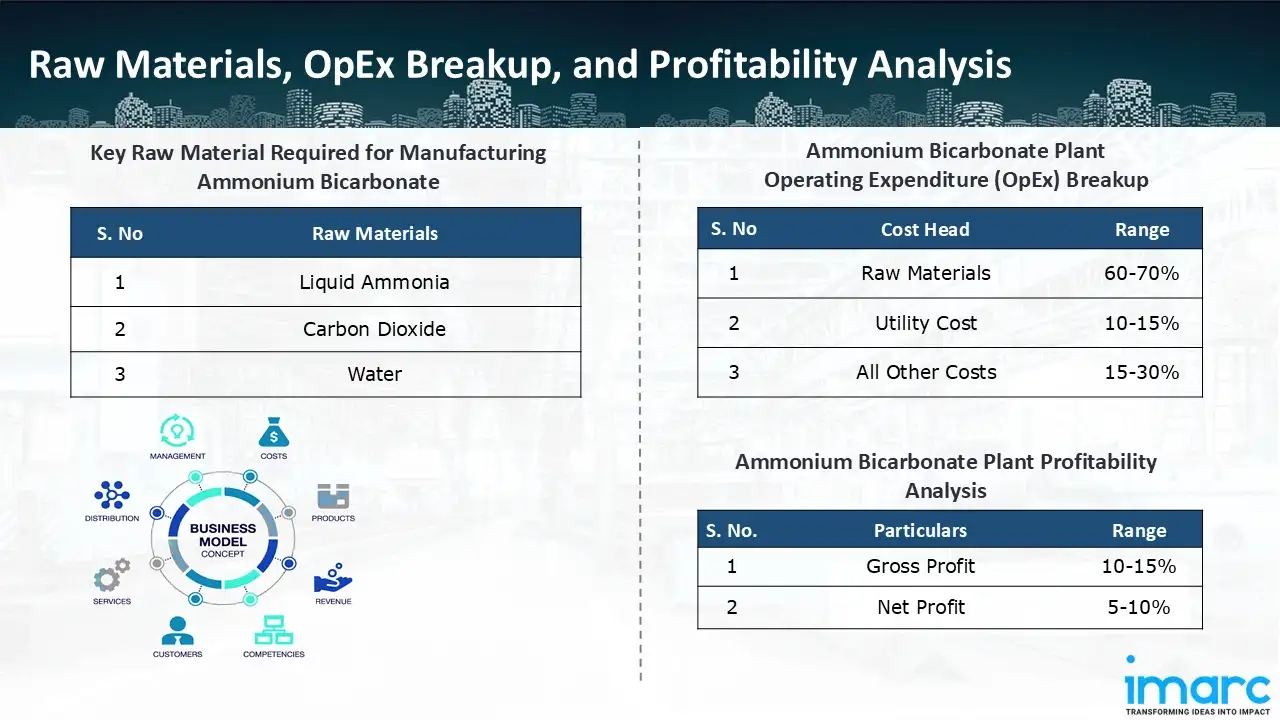

Raw Material Required:

The basic raw materials required for ammonium bicarbonate manufacturing include:

- Liquid Ammonia

- Carbon Dioxide

- Water

Machineries Required:

- Ammonia Storage & Feed System (Refrigerated storage tanks or pressure vessels, pumps and vaporizers)

- Carbon Dioxide Supply (CO2 Supply System, CO2 recovery unit, gas compressors and CO2 storage vessels)

- Water Supply & Treatment System (Deionizers, filters, pumps and storage tanks)

- Absorption Reactor / Carbonation Tower (Vertical packed column or stirred tank reactor, with cooling jackets or heat exchangers)

- Mixers & Agitators

- Controlling Systems (Flow meters, pH sensors and temperature controllers)

- Crystallizer (Cooling or Evaporative) Draft-tube baffle crystallizer, forced circulation crystallizer or batch cooling crystallizer

- Solid-Liquid Separation (Centrifuges (basket or peeler type) vacuum filter, or filter press)

- Dryer (Rotary Drum or Fluidized Bed)

- Cooling Conveyor

- Screening & Sieving Equipment

- Intermediate Product Silos (Equipped with nitrogen blanketing or cooling)

- Automatic Bagging Machines

- Weighing & Sealing Systems (with automatic stitching or heat-sealing)

- Palletizers & Wrapping Machines

- Cooling Water System (Cooling towers and circulation pumps)

- Steam Boiler

- Air Compressors

- Scrubbers / Gas Absorbers and PLC/DCS Control System

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an ammonium bicarbonate manufacturing plant ranges between 60-70%, utility cost ranges between 10% to 15%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 10-15%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the ammonium bicarbonate manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2,500 tons of ammonium bicarbonate annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2024, ADNOC declared that it had successfully acquired OCI Global's 50% + 1 stake in Fertiglobe, boosting its ownership stake to 86.2%, with 13.8% of the firm still in free float on the Abu Dhabi Securities Exchange. It aims to more than double Fertiglobe's ammonia project capacity by integrating its domestic and international portfolio of low-carbon ammonia projects.

- In September 2024, the Nashik Municipal Corporation (NMC) has begun distributing ammonium bicarbonate to devotees at its divisional offices in an effort to increase the immersion of Ganapati idols in households and prevent river pollution.

- In April 2024, the 600 MW Kelvin power station in South Africa, announced the launch of a 300 m³/h carbon capture pilot project to remove CO2, nitrogen oxides, and sulphur oxides, converting them into ammonium bicarbonate crystals for industrial and fertilizer applications. The initiative is a collaboration between CPPE under the Hydrogen Society Roadmap, the Department of Science and Innovation (DSI), Fraunhofer IGB, German agency GIZ, and EPCM Global Engineering.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104