Anhydrous Ferric Chloride Cost Model: The Cost Catalyst

What is Anhydrous Ferric Chloride?

Anhydrous Ferric Chloride, FeCl3, is a corrosive dark brown crystalline chemical that finds extensive application as a major industrial chemical in water treatment, metallurgy, electronic manufacturing, and chemical synthesis industries. It is produced by reacting chlorine gas with iron or ferrous chloride at elevated temperatures to form a high-purity, moisture-free product.

Key Applications Across Industries:

In contrast to its hydrate, anhydrous ferric chloride is not aqueous and is mostly used in processes involving controlled levels of moisture, for example, etching circuits in electronics and as a catalyst in the synthesis of organics. It is used in metallurgy as a chlorinating agent in the production of pure metals, and in the chemical industry, it is used as a Lewis acid catalyst in such reactions as Friedel-Crafts alkylation and acylation. Its capacity for use as a potent oxidizing and dehydrating agent renders it critical to many industrial applications. The increasing use of the compound in printed circuit board (PCB) etching, wastewater treatment, and pigment manufacturing supports its industrial significance. Manufacturers worldwide prioritize enhancing purity levels, corrosion resistance when packaged, and safety to comply with stringent environment and safety requirements. With the development of electronic and wastewater treatment technologies, anhydrous ferric chloride remains at the center stage of contemporary industrial chemistry.

What the Expert Says: Market Overview & Growth Drivers

The global ferric chloride market reached a value of USD 1.54 Billion in 2024. According to IMARC Group, the market is projected to reach USD 2.31 Billion by 2033, at a projected CAGR of 4.2% during 2025-2033. The global market is mostly influenced by the burgeoning electronics industry, where it is widely utilized as an etchant for printed circuit boards (PCBs) and semiconductor components.

As consumer electronics, electric cars, and communications systems are in demand, high purity etching chemical anhydrous ferric chloride is in higher demand. More industrial and municipal wastewater treatment projects globally are also driving consumption, given that ferric chloride is used as a good coagulant and flocculant for the removal of impurities and phosphates. The increased focus on environmental sustainability and more stringent discharge norms in places like North America, Europe, and Asia-Pacific also add to market growth. Additionally, the chemical's function as a catalyst in the manufacture of dyes, pigments, and pharmaceuticals provides a boost to its demand from the specialty chemicals segment. Accelerated industrialization in new economies like India, China, and Southeast Asia is also driving increasing use in metallurgy and water treatment plants. Advances in manufacturing process technologies like the innovation of energy-saving and corrosion-resistant production plants are lowering production costs and enhancing the consistency of quality, stimulating increased use. In addition, mergers and acquisitions and capacity expansion investments by major producers in Europe and Asia are enhancing global supply chains. All these factors put together are likely to bring about consistent growth in the world anhydrous ferric chloride market during the next few years.

Case Study on Cost Model of Anhydrous Ferric Chloride Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale anhydrous ferric chloride manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed anhydrous ferric chloride manufacturing plant in India. This plant is designed to produce 3,500 tons of anhydrous ferric chloride annually.

Manufacturing Process: The process of manufacturing Anhydrous Ferric Chloride (FeCl3) consists of controlled chlorination of iron or ferrous chloride under dry, high-temperature conditions to form a high-purity crystalline compound. The procedure starts with the preparation of raw material, wherein high-quality iron or ferrous chloride (FeCl2) is obtained and refined to eliminate impurities that may influence the chemical stability of the final product. For the chlorination process, dry chlorine gas is fed into a reactor with molten iron or ferrous chloride. At raised temperatures between 300°C and 400°C, the reaction occurs, and the ferric chloride vapors are formed according to the following reactions:

Fe + 3/2Cl2 → FeCl3 or 2FeCl2 + Cl2 → 2FeCl3.

The obtained ferric chloride vapors are next condensed and stored in condensation units under anhydrous conditions to avoid absorption of moisture. The material that is condensed solidifies to become dark brown to black crystalline anhydrous ferric chloride. Purification and filtration procedures follow for quality control of the product, where unwanted impurities like unreacted iron, chlorine residues, or ferrous salts are eliminated by controlled cooling, filtration, and sublimation methods. The purified material is then cooled, pulverized, and filled into air-tight, corrosion-resistant containers (usually glass-lined or polymer-coated steel drums) to avoid moisture entry and stability. Within some recent plants, fluidized bed reactors and computerized chlorine feed controls are employed to maximize reaction efficacy and product consistency with reduced environmental emissions. The entire procedure is carried out under strict safety procedures, as chlorine gas and ferric chloride are highly corrosive and toxic compounds.

Get a Tailored Feasibility Report for Your Project Request Sample

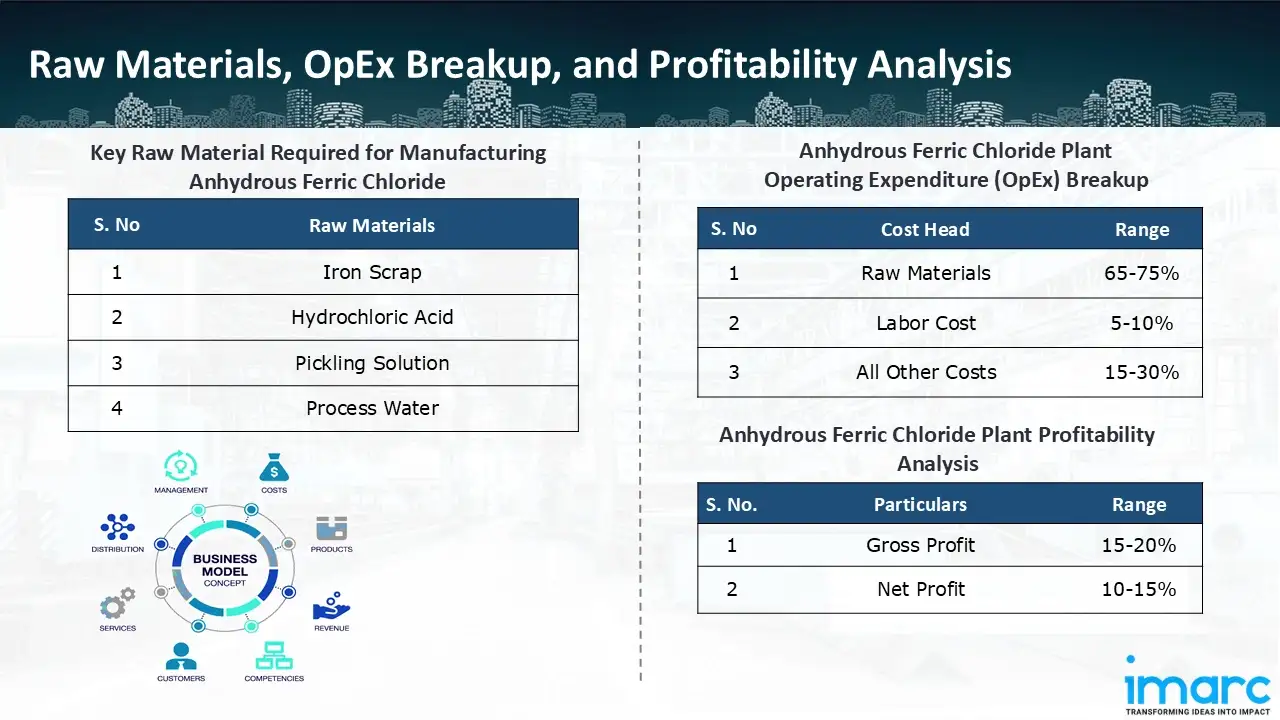

Raw Material Required:

The basic raw materials required for anhydrous ferric chloride manufacturing include:

- Iron Scrap

- Hydrochloric Acid

- Pickling Solution

- Process Water

Machineries Required:

- Raw Material Feeding and Cutting Machines

- Chlorine Storage Tanks and Vaporizer

- Hydrochloric Acid Storage Tanks

- Reactor Vessels

- Heating System

- Agitators

- Gas Scrubbers (Packed Bed / Venturi Scrubbers)

- Blowers

- Exhaust Fans

- Gas Absorption Towers (FRP / Rubber-Lined Steel)

- Pressure Filter / Leaf Filter

- Settling Tanks

- Evaporator (Multi-Effect Evaporator, Falling Film, or Forced Circulation Type)

- Vacuum Pumps

- Storage Tanks (FRP, Rubber-Lined Steel, HDPE Tanks)

- Drum Filling Machines / Tank Truck Loading Systems

- Water Treatment Unit

- Cooling Towers / Heat Exchangers

- Instrumentation & Control System (PLC/DCS With Acid-Proof Sensors)

- Interconnect Welding Machine

- Housing Assembly Line

- Insulation And Terminal Assembly Tools

- Battery Analyzer / Tester

- Leak Testing Equipment

- Environmental Chamber

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an anhydrous ferric chloride manufacturing plant ranges between 65-75%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the anhydrous ferric chloride manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 3,500 tons of anhydrous ferric chloride annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2024, Kemira makes an investment to increase its ferric chloride capacity in Tarragona, Spain, in order to produce the BDP (Biogas Digestion Product), a particular biogas product. Kemira's ability to meet the increasing demand for biogas applications in Europe will be facilitated by this investment. Additionally, the most popular coagulant for phosphorus reduction in wastewater treatment is ferric chloride. Operation of the capacity is anticipated in 2026, with a total investment in the mid-single digits.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104