Glucose Powder Manufacturing Cost Analysis: A Cost Intelligence Report

What is Glucose Powder?

Glucose powder is a crystalline or powdered form of a simple sugar, glucose, derived mainly from sources of starch: corn, wheat, or rice. Glucose powder is obtained by the hydrolysis of starch into glucose by enzymes, followed by purification and concentration of the solution and its drying to yield a readily water-soluble, easily digested carbohydrate powder. Glucose powder is an instant source of energy as it is quickly absorbed in the body, which makes the product valuable in food, beverage, nutraceutical, and pharmaceutical applications. It has a neutral taste, a very high sweetness index compared to regular sugar, and excellent dissolving properties, making it useful in various industrial formulations and household consumption.

Key Applications Across Industries:

Glucose powder finds extensive applications in food, beverages, pharmaceuticals, nutraceuticals, and personal care industries because of the functional properties it renders, which include sweetness, solubility, energy release, and texturizing ability. The food industry uses glucose powder in confectionery, bakery products, ice creams, jams, and desserts to enhance sweetness, improve browning, maintain moisture, and stabilize texture. It is also used as a bulking agent, preventing crystallization in candies and syrups. In beverages, it finds its place in energy drinks, oral rehydration solutions, instant mixes, and sports formulations, where rapid delivery of energy is crucial.

Glucose powder is one of the key ingredients in oral electrolyte supplements, glucose tablets, IV solutions, and drugs whose formulation requires an easily metabolizable sugar base within the pharmaceutical industry. Glucose powder is used as a carrier or stabilizer in dry powder formulations. Nutraceuticals intended for the athletic population and for those individuals who need quick energy replenishment include protein powders, fortified foods, and recovery supplements that contain glucose powder.

Beyond food and health sectors, glucose powder finds inclusion in cosmetic and personal care formulations as a humectant, stabilizer, and fermentation substrate. Its industrial applications also include use in fermentation processes, animal feed formulation, and various chemical manufacturing operations when a carbohydrate source is required.

What the Expert Says: Market Overview & Growth Drivers

The global glucose powder market reached a value of USD 7.01 Billion in 2024. According to IMARC Group, the market is projected to reach USD 10.22 Billion by 2033, at a projected CAGR of 4.3% during 2025-2033. The global glucose powder market is driven by rising demand across food manufacturing, healthcare, sports nutrition, and industrial applications, each contributing to consistent growth. One of the strongest drivers is the expansion of the processed food and beverage industry, within which glucose powder is valued for its sweetness, stabilizing ability, and functionality in bakery, confectionery, dairy, and beverage applications. Consumer demand is shifting toward ready-to-eat and ready-to-drink products; hence, glucose powder remains preferred among manufacturers due to its ease of blending, mouthfeel improvement, and extension of product shelf life.

Another driver is the increasing consciousness of health and wellness, especially in sports and fitness. These athletes want a quick source of energy, hence there is demand for energy drinks, glucose sachets, and oral rehydration solutions. Awareness among consumers of the prevalence of dehydration, management of fatigue, and quick restoration of energy, particularly in tropical and developing regions, thereby supports the consumption of glucose-based hydration products. Glucose powder is an important constituent in pharmaceutical and nutraceutical formulations pertaining to pediatric care, elderly nutrition, electrolyte mixes, and medical recovery solutions. The increasing preventive healthcare and home-based medical treatments also contribute to the growth rate. Glucose powder is also an important feedstock into industrial fermentation processes comprising enzyme manufacture, biotechnology, and certain chemical processes, which supports growth from the industrial value chain. This, in turn, has led to increased intake of processed foods and nutritional supplements due to economic and demographic factors such as urbanization, improved disposable incomes, and lifestyle-related changes. And on top of this, improved starch-processing technology and the expansion of corn and wheat processing industries made glucose powder more accessible and cost-effective for manufacturers. In aggregate, these dynamics reinforce glucose powder’s importance across multiple sectors, supporting strong global market momentum.

Case Study on Cost Model of Glucose Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale glucose powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed glucose powder manufacturing plant in India. This plant is designed to manufacture 5,000 tons of glucose powder annually.

Manufacturing Process: Glucose powder is produced from starch-rich raw materials, mainly corn, wheat, cassava, or rice, through a multi-step process involving enzymatic treatment, filtration, and drying. The process initially entails starch extraction, wherein cleaned grains or tubers are steeped, milled, and separated to obtain a refined starch slurry. This slurry then undergoes liquefaction, wherein the slurry is mixed with water and heated in the presence of alpha-amylase enzymes. The long-chain starch molecules are broken into shorter dextrins by liquefaction, which reduces viscosity and prepares the mixture for further hydrolysis. The slurry, rich in dextrin, now undergoes saccharification, a very important stage where glucoamylase enzymes break down the dextrins into glucose molecules by releasing the individual units of glucose. After saccharification, this glucose-rich solution is passed through filtration, carbon treatment, and ion-exchange systems to remove proteins, pigments, minerals, and other impurities. These purification steps result in a clear glucose solution of high purity suitable for use in food, pharmaceutical, and industrial applications. Under vacuum, the liquid is concentrated to increase the solid content, and thus a thick glucose syrup is obtained. This syrup is further spray-dried into powder by atomizing the syrup into fine droplets that are then quickly dried by hot air, yielding a free-flowing crystalline powder. Alternatively, some producers use drum drying or crystallization followed by milling. The final glucose powder is then sieved to achieve uniform particle size and packed in moisture-resistant, food-grade packaging to prevent clumping and maintain stability. Control tests run throughout the production process monitor the glucose content, moisture levels, microbial safety, and solubility of the product. This very controlled process makes sure that a high-quality product is produced, which is suitable for food processing, pharmaceutical applications, beverages, and nutraceutical formulations.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

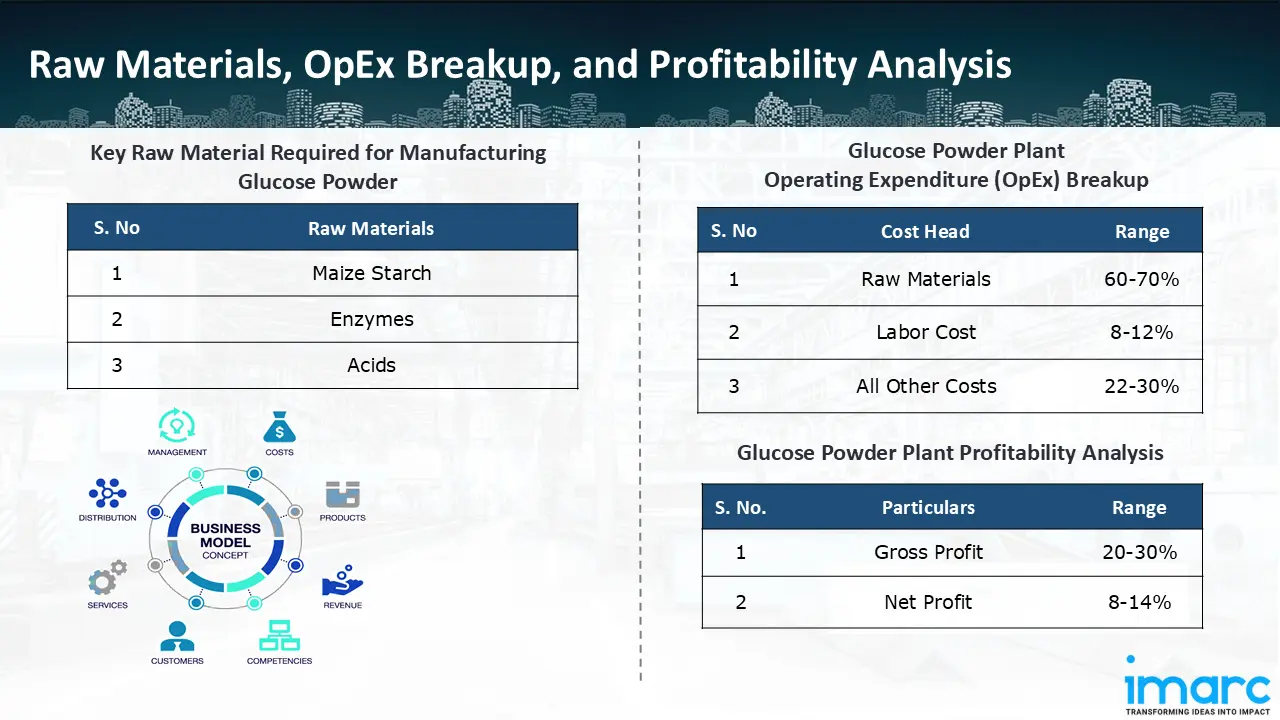

The basic raw materials required for glucose powder manufacturing include:

- Maize Starch

- Enzymes

- Acids

Machine Section or Lines Required:

- Hydrolysis Tanks

- Evaporator

- Dryer

- Grinding

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in glucose powder manufacturing plant ranges between 60-70%, labor cost ranges between 8% to 12%, and all other costs ranges between 22-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-30%, and net profit lie between the range of 8-14% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the glucose powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 5,000 tons of glucose powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In November 2024, Tate & Lyle announced that it had successfully acquired all of the issued share capital of CP Kelco U.S., CP Kelco China, and CP Kelco ApS, along with each of their respective subsidiaries. CP Kelco is a prominent supplier of pectin, speciality gums, and other natural ingredients.

- In May 2024, Dabur GlucoPlus-C, a player in glucose category, has expanded its portfolio and entered the ready-to-drink glucose category with the launch of 'Dabur GlucoPlus-C Instant Energy Drink' in a PET bottle, in a tasty tangy orange variant.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104