Biodiesel Cost Model: Economic Insights from the Biodiesel Manufacturing

What is Biodiesel?

Biodiesel is a renewable and biodegradable fuel source mainly from vegetable oils, animal fats, or waste cooking oils, and can serve as a direct replacement or blend with traditional petroleum diesel. It is chemically constituted by fatty acid methyl esters (FAMEs), which are formed when triglycerides react with methanol or ethanol in the presence of a catalyst under transesterification.

Key Applications Across Industries:

Biodiesel can be used in most diesel engines and provides comparable energy density while cutting emissions of harmful pollutants like particulate matter, carbon monoxide, and unburned hydrocarbons by quite a lot. Biodiesel is also nontoxic and naturally decomposes in the environment, so it is an environmentally friendly substitute for fossil fuel. The scale of biodiesel production varies from small local refineries to big industrial plants, depending on the availability of feedstocks and local demand. Soybean oil in the US, rapeseed oil in the EU, palm oil in Southeast Asia, and waste cooking oil worldwide are major feedstocks, mirroring local agricultural trends. Biodiesel is extremely prevalent in the transport sector, especially for trucks, buses, and ships, and in power generation in CHP stations. Government policies like mandatory blending obligations, renewable fuel policies, and taxation incentives are major drivers of its adoption. Furthermore, technology improvements in feedstock diversification, such as non-food crops and algae oils, are expanding the horizon of biodiesel production while reducing food-versus-fuel issues. In general, biodiesel is a key element of the world's shift toward renewable and sustainable energy options that reconcile environmental advantages with energy security benefits.

What the Expert Says: Market Overview & Growth Drivers

The global biodiesel market reached a value of USD 46.1 Billion in 2024. According to IMARC Group, the market is projected to reach USD 63.4 Billion by 2033, at a projected CAGR of 3.6% during 2025-2033. Global biodiesel demand is driven mainly by the growing need for renewable energy and lowering greenhouse gas emissions from the transport sector.

Governments globally are enforcing compulsory biodiesel blending requirements, including B5, B10, and beyond, in a bid to cut fossil fuel reliance and address climate change targets. Renewable energy policies, subsidies, and tax credits motivate consumers and producers alike to use biodiesel, provided that it is a stable regulatory framework that promotes market growth. An increase in crude oil prices and energy security issues further accelerate the use of biodiesel, as nations look towards alternative fuels produced domestically to minimize reliance on foreign petroleum. The environmental advantages of biodiesel in terms of lower carbon dioxide, sulfur, and particulate emissions make it a choice in urban centers and emission-control regions. Also, the availability of alternative feedstocks such as rapeseed, palm, soybean, and used cooking oil, in addition to advances in high-yield and non-food crops, is improving production scale and decreasing costs. Growing world concern about climate change and sustainability, along with corporate efforts towards net-zero, has supported low-carbon fuel demand in transport and industrial uses. Developing economies in Asia-Pacific, Latin America, and Africa are experiencing fast growth driven by increasing vehicle fleets, government regulations, and renewable fuel programs. Meanwhile, studies on second-generation biodiesel sources such as algae and waste oils are also poised to increase adoption by dispelling food-versus-fuel debates. Overall, these considerations situate biodiesel as a key renewable fuel source in the global shift toward cleaner, more sustainable transportation fuels.

Case Study on Cost Model of Biodiesel Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale biodiesel manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed biodiesel manufacturing plant in India. This plant is designed to produce 120 tons of biodiesel per day.

Manufacturing Process: The production of biodiesel is mainly a process of chemical transformation of the fats and oils like vegetable oil, animal oils, or waste cooking oils into fatty acid methyl esters (FAMEs) by a process known as transesterification. Here, triglycerides, which are the dominant components of fats and oils, react with an alcohol, most commonly methanol or ethanol, under the action of a catalyst like sodium hydroxide (NaOH) or potassium hydroxide (KOH). The reaction hydrolyses the triglycerides into biodiesel and glycerol, with glycerol generally fractionated as a by-product. Before transesterification, feedstocks may be pre-treated to de-free fatty acids, water, and contaminants that might otherwise hinder the reaction or contaminate the final product. Upon completion of the transesterification reaction, the mixture is left to settle or is centrifuged to settle out glycerol, which is further purified for industrial or pharmaceutical purposes. The crude biodiesel is washed with water or is treated chemically to eliminate the leftover catalyst, methanol, and soap by-products. After purification, the biodiesel is dried to eliminate all traces of moisture and thereafter analysed for important fuel characteristics like viscosity, density, acid value, and flash point in order to meet international standards such as ASTM D6751 or EN 14214. Current biodiesel manufacturing plants can also include continuous flow reactors, enzymatic catalysts, or supercritical alcohol processes to enhance yield and efficiency. The end product is either pure biodiesel (B100) or blended with petroleum diesel in different proportions (B5, B20, etc.), which is fully compatible with conventional diesel engines without increasing greenhouse gas emissions, sulfur content, and particulate matter. This process underscores biodiesel as a renewable, environmentally friendly substitute for conventional fossil diesel fuels.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

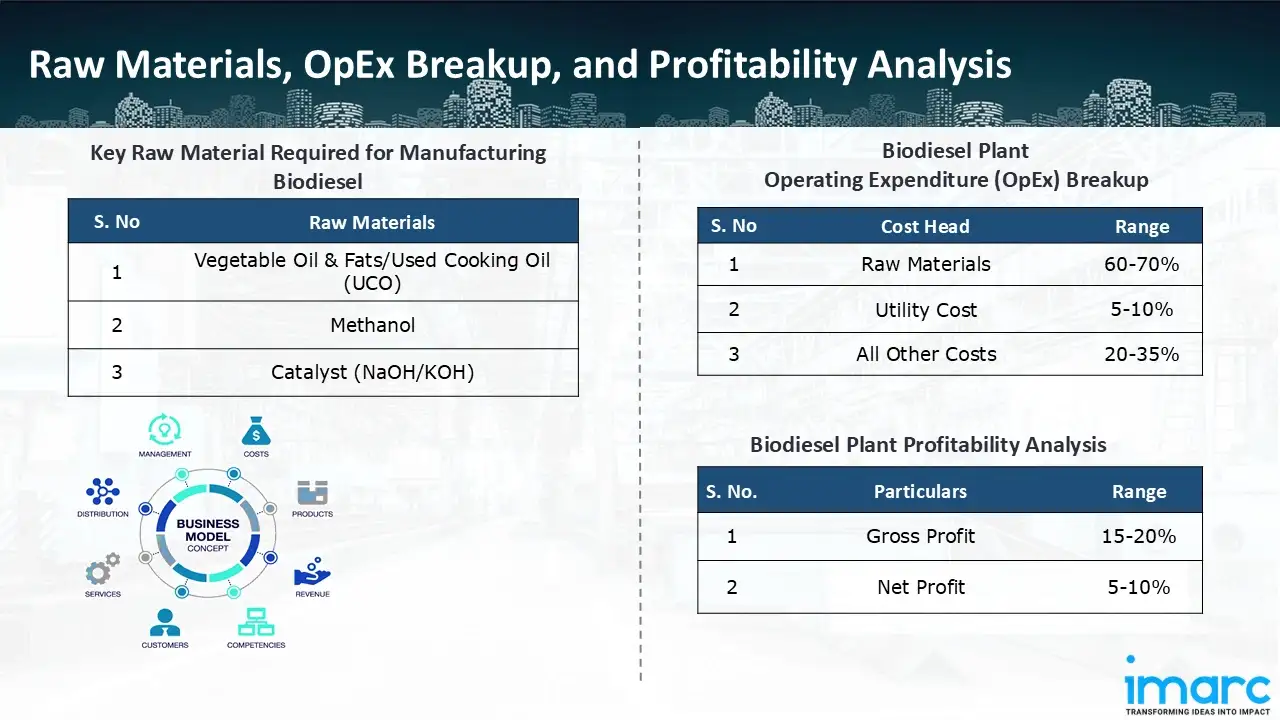

The basic raw materials required for biodiesel manufacturing include:

- Vegetable oil and fats/Used Cooking Oil (UCO)

- Methanol

- Catalyst (NaOH/KOH)

Machineries Required:

- Feedstock Preparation

- Oil Storage Tanks

- Heating Systems (Steam/Oil Heaters)

- Filtering Systems

- Degumming Unit (Acid Treatment + Centrifuge)

- Neutralization Reactor (For FFA Removal If >3–5 %)

- Drying Column / Vacuum Dryer

- Alcohol & Catalyst Preparation

- Catalyst Dissolver Tank with Agitator

- Methanol Storage & Dosing System

- Pumping System

- Transesterification Reaction

- Continuous Stirred-Tank Reactor (Cstr) Or Batch Reactor

- Heating Jacket (60–65 °C)

- Agitators

- Phase Separation

- Decanter / Gravity Settling Tanks

- High-Speed Centrifuge

- Methanol Recovery

- Distillation Column (Flash or Vacuum)

- Condensers

- Methanol Storage Tanks

- Biodiesel Washing & Drying

- Washing Column / Bubble Washer or Dry-Wash System (Ion-Exchange Resins / Magnesium Silicate)

- Water Treatment Unit

- Vacuum Dryer / Flash Evaporator

- Glycerol Purification

- Neutralization Reactor

- Distillation System (For Methanol Recovery)

- Evaporator (To Concentrate Glycerol)

- Storage Tanks

- Final Storage & Dispatch

- Biodiesel Storage Tanks (Ms/Ss, Heated)

- Transfer Pumps

- Loading Bay Facilities

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a biodiesel manufacturing plant ranges between 60-70%, utility cost ranges between 5% to 10%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the biodiesel manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 120 tons of biodiesel per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Indonesia has declared that it will stop importing any diesel fuel starting in the second half of 2026, marking a significant step towards energy independence. This choice comes as the nation intends to completely execute its B50 biodiesel requirement, which stipulates that 50% of fuel must be biodiesel.

- In October 2025, the Iowa Renewable Fuels Infrastructure Program (RFIP) board has authorised 48 new awards totalling over US$ 1.86 million to promote expanding biofuel infrastructure throughout the state, according to a statement released by the Iowa Secretary of Agriculture. The goal of the 48 initiatives, which cover 25 counties, is to make cleaner-burning fuels like biodiesel and E15 (Unleaded 88) more affordable for drivers.

- In September 2025, Brazilian soybean crushers announced plans to increase its crushing capacity by more than US$ 1.11 billion (5.9 billion reais) over the course of the upcoming year in response to the growing demand for biodiesel. It is expected that the number of soybean-crushing businesses in the nation will rise from 67 to 75 by 2025, and the number of plants will expand from 132 to 144.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104