Ice Cream Manufacturing Cost Analysis: Process Economics Report

What is Ice Cream?

Ice cream is a frozen dairy dessert made by blending milk, cream, sugar, and flavorings, then freezing the mixture while incorporating air to give a smooth, creamy texture. The mixture is pasteurized, homogenized, then churned under controlled conditions to prevent the formation of large ice crystals. Depending on the recipe and product category, it may contain stabilizers, emulsifiers, fruits, nuts, chocolate, or other inclusions. It comes in hardpacked ice cream, softserve, gelato, sorbets, and frozen yogurt. The texture, flavor, and quality of this frozen dessert will depend on the ratios of ingredients used and the techniques followed in processing.

Key Applications Across Industries:

Ice cream can be put to a wide range of culinary, commercial, and industrial uses because of its versatility, flavor adaptability, and universal appeal. In the foodservice industry, ice cream is a staple dessert offered in restaurants, cafés, fast-food chains, bakeries, and ice-cream parlors. It is served in cones, cups, sundaes, shakes, floats, and elaborate plated desserts. Specialty formats like gelato, rolled ice cream, soft-serve, and nitrogen-infused varieties allow businesses to differentiate their offerings and enhance consumer experience. In retail markets, packaged ice cream is sold in tubs, bars, sticks, sandwiches, and multipacks, catering to household consumption and on-the-go snacking.

It also plays a main role in the menus of quick-service restaurants, where shakes, McFlurries-style mixes, and soft-serve cones drive store traffic and brand identity. In the bakery and confectionery sectors, it is used in value-added applications such as icecream cakes, mochi ice cream, and frozen novelties. In addition, the rise of functional and better-for-you categories, including high-protein, low-sugar, vegan, and probiotic-rich formulations, extends its application to the health-conscious consumer segment. Seasonal and festival-based innovations, such as limited-edition flavors or thematic desserts, further extend its use in marketing and promotional activities. All in all, ice cream's versatility for a wide range of flavors, textures, and consumer tastes from different cultures makes the product pivotal in the food retail and foodservice sectors.

What the Expert Says: Market Overview & Growth Drivers

The global ice cream market reached a value of USD 80.9 Billion in 2025. According to IMARC Group, the market is projected to reach USD 105.6 Billion by 2034, at a projected CAGR of 2.90% during 2026-2034. Growth in the global ice cream market is informed by changing consumer needs and preferences, increasing disposable incomes, innovation in flavors and formats, improvement in cold-chain infrastructure, and retail penetration. One of the most significant factors has been the growth of urbanization and growing middle-class populations in developing countries. As consumers get busier and their lives more convenience-oriented, indulgent ready-to-eat products like ice cream see increased demand.

Other significant drivers are product innovations. Premium, artisanal, plant-based, keto, and high-protein ice cream options from manufacturers hit the shelves to fit different diets and wellness trends. The diversification of product categories opens up opportunities for both the traditional consumer of ice cream and new segments interested in healthier or more adventurous flavor experiences. Limited-edition launches, international flavor influences, and textural innovations—like mix-ins, swirls, and layered formats—achieve strong marketing traction.

Increased accessibility also comes from the growth of e-commerce and food-delivery platforms. In-store purchases of ice cream have increasingly given way to online orders, as better packaging technology and last-mile cold-chain capacity come online. Growth in modern retail-supermarkets, hypermarkets, and convenience stores-also builds product availability and visibility.

Technological advancements in process efficiency, automation, and frozen logistics have reduced production costs while enhancing product quality. Improvement of cold-chain infrastructure in developing markets, more so, is crucial and allows manufacturers access to rural and semi-urban areas.

Additionally, ice cream consumption benefits from its strong emotional and social appeal, often associated with enjoyment, celebration, and indulgence. Marketing strategies that tap into these sentiments—like nostalgia, seasonal campaigns, and influencer-led promotions—continue to strengthen global demand. Together, these drivers underpin steady growth in both established and emerging world ice cream markets. In the manufacture of ice cream, there are a number of carefully controlled steps involved in making a smooth, stable, and flavorful frozen product.

Case Study on Cost Model of Ice Cream Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale ice cream manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ice cream manufacturing plant in India. This plant is designed to manufacture 1,500 kilo liters of ice cream annually.

Manufacturing Process: Production begins with the preparation of a liquid mix, in which milk and cream are combined with sugar, stabilizers, and emulsifiers and flavor bases to achieve a desired formulation. The mixture is combined in such a way that uniform distribution of ingredients is achieved. The liquid mix is then subjected to the process of pasteurization, in which heating destroys unwanted microorganisms; this improves product safety. Immediately following, the mix is homogenized under high pressure, which forces fat globules into small particles to ensure a smoother texture and help prevent separation during freezing. After homogenization, the mixture is cooled in an aging tank at low temperature (usually 2–5°C) for a number of hours. Aging enhances the emulsification process and the water-binding properties of the stabilizers; it also allows time for crystallization of the fat to take place, all factors contributing to better body and texture when the product is frozen. The aged mixture is then pumped into a continuous freezer, where it is whipped while being partially frozen. At this stage, air, or overrun, is incorporated into the mix, giving ice cream its light and creamy texture. The extent of overrun depends on the type of product desired; premium ice creams contain less air and so present denser textures. Inclusions like chocolate chips, nuts, pieces of fruit, or sauces can be mixed in through ingredient feeders after the initial freezing. The semifrozen ice cream then undergoes extrusion into cartons, tubs, or molds and is moved into a hardening tunnel where rapid freezing at −30°C to −40°C solidifies the product and stabilizes its microstructure. Finally, hardened ice cream is packaged and, to preserve quality until consumption, is stored at low temperatures and distributed through frozen supply chains.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

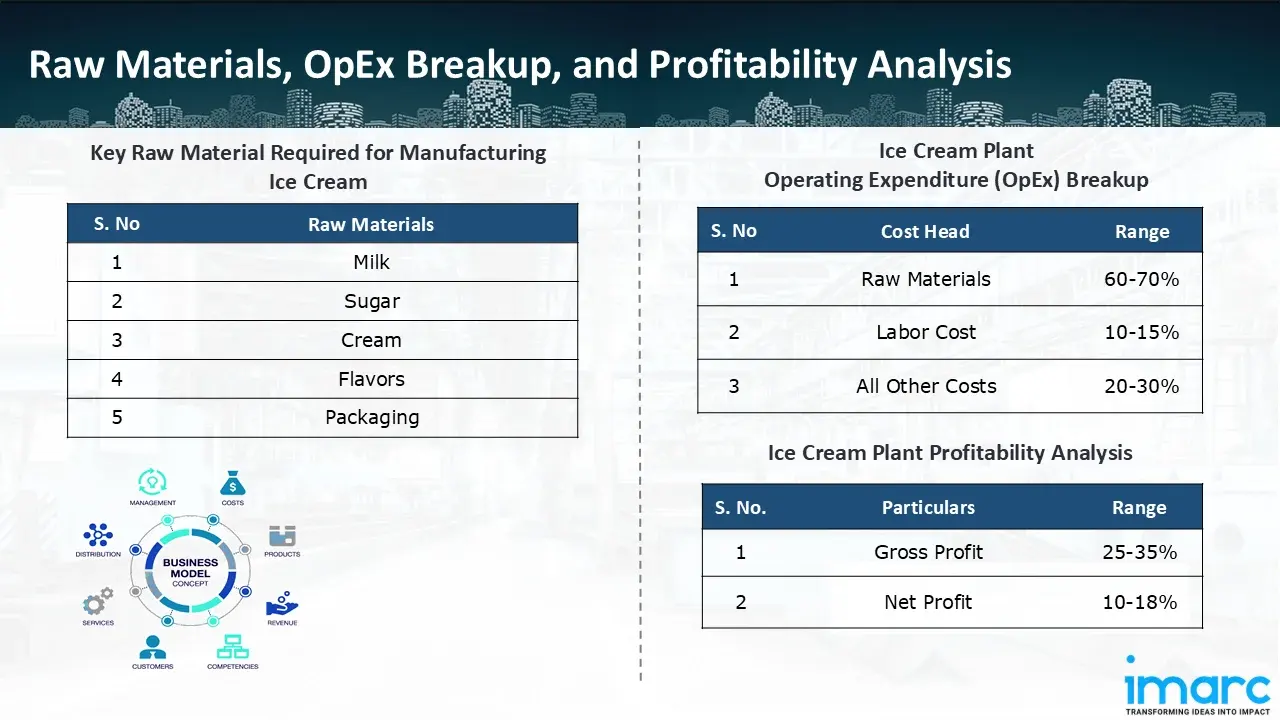

The basic raw materials required for ice cream manufacturing include:

- Milk

- Sugar

- Cream

- Flavors

- Packaging

Machine Section or Lines Required:

- Pasteurization

- Homogenization

- Freezing

- Hardening

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in ice cream manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-35%, and net profit lie between the range of 10-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the ice cream manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1,500 kilo litres of ice cream annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Hindustan Foods (HFL) has authorised an investment of Rs. 30 crores for the purchase of a company through its fully owned subsidiary company, that makes ice cream cones and sleeves. With a capacity of around one million cones per day, this acquisition represents HFL's entry into the cone manufacturing industry. The biggest international ice cream manufacturer in India is one of the existing clients.

- In September 2025, the U.S. subsidiary of India’s Vadilal Industries announced its plans to start manufacturing ice cream at its local facility by the year-end to reduce dependence on imports and boost sales.

- In July 2024, Lotte Wellfood Co. Ltd.'s Havmor Ice Cream would invest Rs 400 crore in its future Pune factory. With a starting capacity of 2 lakh litres per day, the company plans to begin commercial production at its new facility next year. By 2026, that capacity will be raised to 4 lakh litres.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104