Bioethanol Cost Model: A Comprehensive Look at Production Economics

What is Bioethanol?

Bioethanol is a biodegradable, renewable alcohol that is made by fermenting sugars from biomass resources like corn, sugarcane, wheat, cassava, and cellulosic materials like agricultural waste and forest residues. It is cleaner than gasoline from fossil fuels and provides valuable decreases in greenhouse gases and helps to move us toward sustainable energy systems.

Key Applications Across Industries:

The process of production of bioethanol is mainly about the conversion of biomass carbohydrate to simple sugars by hydrolysis and subsequent fermentation by yeast or bacteria into ethanol. The end product is distilled and dried to the level of fuel purity. Bioethanol is extensively applied as a biofuel blend in transport, habitually blended with gasoline in different percentages (e.g., E10, E15, or E85) to boost octane numbers and lower the emissions of carbon monoxide and hydrocarbons. Aside from its use as an automotive fuel, bioethanol is also applied as an industrial solvent, in the pharmaceutical, cosmetics industries, and the manufacture of alcoholic drinks. New developments in second-generation (2G) and third generation (3G) bioethanol technologies that make use of non-food biomass resources like crop residues, waste wood, and algae are alleviating food-versus-fuel competition concerns. With world energy policies focusing on decarbonization and energy diversification, bioethanol has become a central renewable fuel enabling energy security, rural economic growth, and carbon neutrality.

What the Expert Says: Market Overview & Growth Drivers

The global bioethanol market reached a value of USD 10.71 Billion in 2024. According to IMARC Group, the market is projected to reach USD 18.67 Billion by 2033, at a projected CAGR of 6.05% during 2025-2033. The global bioethanol industry is dominated by the increasing need for cleaner and renewable fuels in the face of intensifying climate change and carbon footprint concerns.

Governments across the globe are putting in place blending mandates and decarbonization objectives like India's Ethanol Blended Petrol (EBP) initiative aiming 20% blending in 2025, the U.S. Renewable Fuel Standard (RFS), and the European Union's Renewable Energy Directive (RED II), to minimize fossil fuel dependency and encourage renewable energy use. These policies have played a major role in enhancing the production and use of bioethanol worldwide. Another major driver is the availability of farm feedstocks, especially in nations such as Brazil, the U.S., and India, where sugarcane, corn, and molasses are easily available, facilitating low-cost production. Also, the emergence of next-generation bioethanol technologies, including cellulosic and algae-based ethanol, is increasing feedstock flexibility and enhancing production efficiency and reducing lifecycle emissions. The increasing use of flex-fuel vehicles (FFVs), particularly in Latin America and Asia-Pacific, is further driving market demand. The economic benefits of bioethanol production like job and rural income generation, and the use of agricultural waste also foster its increasing world market share. Additionally, the growing interest of oil majors and energy corporations in low-carbon fuel portfolios and carbon capture and utilization (CCU) integration with ethanol facilities is transforming industry dynamics. Together, environmental factors, friendly regulations, and technological advancements are driving consistent growth within the global bioethanol market.

Case Study on Cost Model of Bioethanol Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale bioethanol manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed bioethanol manufacturing plant in India. This plant is designed to produce 30 tons of bioethanol per day.

Manufacturing Process: The process of manufacturing bioethanol involves a series of biochemical and physical processes aimed at converting biomass that contains carbohydrates to ethanol. The procedure starts with feedstock selection and preparation, in which raw materials such as sugarcane, corn, wheat, cassava, or lignocellulosic biomass (e.g., crop residues or wood chips) are milled and cleaned to enhance surface area for further processing. The second step involves hydrolysis, in which complex carbohydrates like starch or cellulose are dissolved into simple sugars. For feedstocks based on starch, alpha-amylase and glucoamylase are employed to break down the starch into glucose, whereas lignocellulosic feedstocks are subjected to acid, steam, or enzyme pretreatment in order to liberate fermentable sugars such as glucose and xylose. After sugars become accessible, the fermentation process is initiated. During this phase, microorganisms like Saccharomyces cerevisiae (yeast) break down the sugars into ethanol and carbon dioxide under controlled temperatures of pH, temperature, and oxygen. The fermentation process usually takes anywhere from 30 to 72 hours, depending on the feedstock and efficiency of the process. Once fermented, the resulting liquid "beer" has 8–12% ethanol, which is subsequently distilled in order to isolate ethanol from water and other contaminants. The ethanol then further undergoes purification by dehydration, commonly utilizing molecular sieves, to yield anhydrous ethanol (99.5% purity) for blending as fuel. In higher second-generation bioethanol production, non-food biomass is used, involving pretreatment and enzymatic hydrolysis technologies to maximize yield. The whole process focuses on energy efficiency and sustainability and usually involves cogeneration systems for the recycling of process heat and emissions reduction, making bioethanol a clean and renewable energy fuel.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

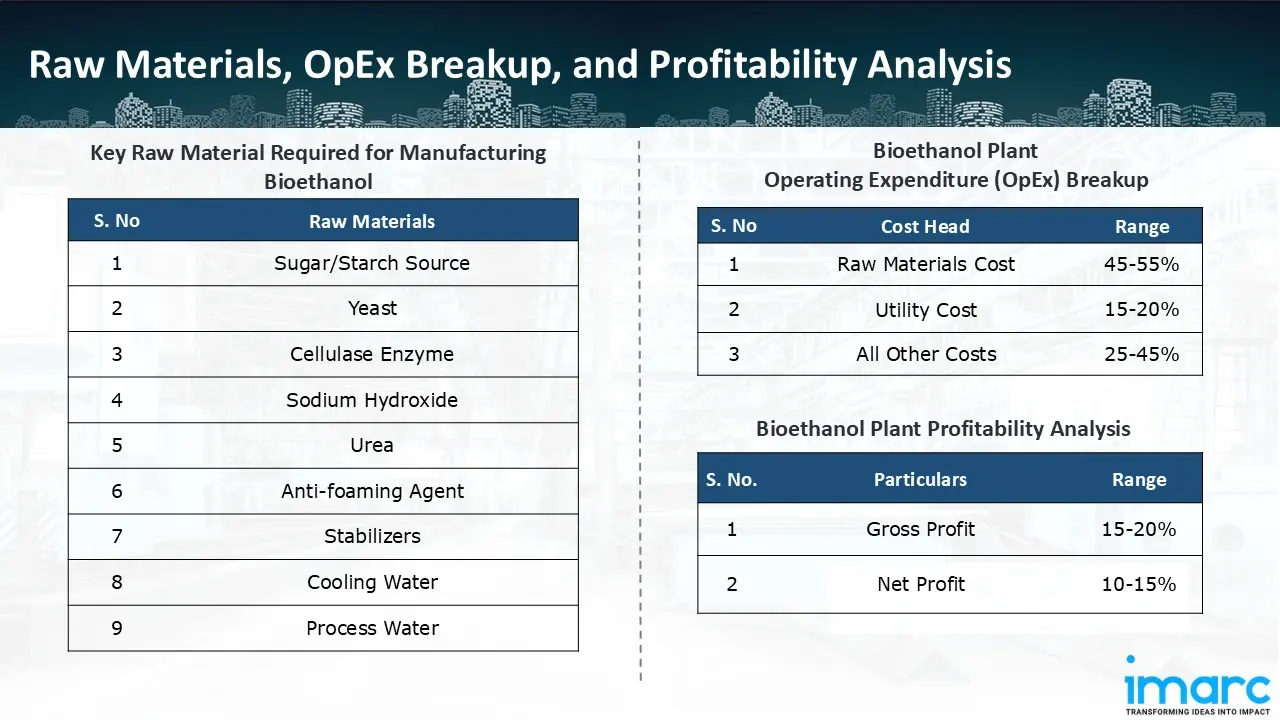

The basic raw materials required for bioethanol manufacturing include:

- Sugar/Starch Source

- Yeast

- Cellulase Enzyme

- Sodium Hydroxide

- Urea

- Anti-foaming Agent

- Stabilizers

- Cooling Water

- Process Water

Machineries Required:

- Grain Receipt and Storage Unit

- Grain Handling and Milling Unit

- Slurry Preparation Unit /Liquefaction Unit

- Saccharification and Fermentation Unit

- Multi-Pressure Distillation Unit

- Boiler

- MSDH

- Decantation Unit

- Multi-Effect Evaporation System

- Water Treatment Unit

- DDGS

- Dryer & Storage Units

- Packaging Unit

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a bioethanol manufacturing plant ranges between 45-55%, utility cost ranges between 15% to 20%, and all other costs ranges between 25-45% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the bioethanol manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 30 tons of bioethanol per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Japan Airlines has made an investment in the MORISORA Bio Refinery to promote environmentally friendly aviation fuel made from bioethanol derived from woody biomass. Three businesses, Nippon Paper Industries, Sumitomo Corporation, and Green Earth Institute formed the joint venture MORISORA Bio Refinery in July 2025.

- In September 2025, NSL Sugars, has given MEDAS EnggDesign (MEDAS), a leading provider of distillery, brewery, and food processing solutions, a sizable contract. The Jai Mahesh Unit of NSL Sugars, situated near Mazalgaon, is covered by the contract. The factory can produce 500,000 litres of sugarcane syrup and grains every day. As part of the Government of India's National Biofuel Policy, the new facility, which is based on MEDAS's state-of-the-art design, will generate fuel-grade ethanol using a variety of feedstocks, including grains and sugarcane syrup.

- In September 2025, India's government has declared that, as of November 1, all quantitative limitations for the production of ethanol from sugarcane juice, syrup, and all forms of molasses will be lifted for the 2025–2026 ethanol supply year. The ruling represents a major change in policy that will help sugar mills, increase the production of renewable energy, and help India meet its goals for biofuel blending.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104