Biomass Pellets Manufacturing Cost Analysis: A Deep Dive into Manufacturing Economics

What is Biomass Pellets?

Biomass pellets are a sustainable, carbon-neutral, and renewable source of energy made from organic materials such as forestry waste, agricultural residues, sawdust, wood chips, and other biomass feedstocks. Biomass pellets are small, cylindrical in shape, and usually between 6 and 12 millimeters in diameter and are utilized as a clean energy alternative to fossil fuels in power production, heating, and for industrial purposes. The production process of biomass pellets comprises drying, grinding, pressing, and cooling biomass under high pressure without any chemical binders—the natural lignin of the wood serves as a binder, giving structural strength to the pellets. Owing to their high energy density, uniform dimensions, and convenience of transport and storage, biomass pellets are increasingly becoming a popular sustainable source of energy in various industries. Biomass pellets are a central element in the energy transition around the world, particularly in countries working to diminish reliance on oil and coal.

Key Applications Across Industries:

They are utilized in biomass boilers, co-firing power stations, and domestic heating, providing impressive carbon dioxide emission reductions relative to conventional fuels. The pellets also support circular economy efforts by recycling agricultural and forestry waste that would otherwise be wasted. With improved pelletizing technology and the growth of bioenergy policies across the globe, biomass pellets have emerged as the linchpin of renewable energy policy in Europe, North America, and Asia-Pacific. Their adaptability, affordability, and fit with carbon reduction policies make them a critical component of the sustainable energy future.

What the Expert Says: Market Overview & Growth Drivers

The global biomass pellets market reached a value of USD 10.14 Billion in 2024. According to IMARC Group, the market is projected to reach USD 16.41 Billion by 2033, at a projected CAGR of 4.80% during 2025-2033. The global biomass pellets market is fueled by mounting demand for renewable and sustainable energy in light of rising fears about climate change and the scarcity of fossil fuels. Governments globally are enacting tough targets for carbon reductions and championing the use of biomass energy as part of their net-zero emission policies, which majorly enhances the demand for biomass pellets. For example, the European Union, Japan, and South Korea have policies in place supporting the utilization of biomass co-firing at power plants to subtitute for coal, which is a strong market driver.

Furthermore, increasing use of biomass-based heating systems in buildings and industry enhances market growth, particularly in colder climates where there is greater demand for heating. Biomass pellets provide a cleaner and more efficient substitute for conventional firewood and coal, emitting lower pollution levels and less ash. The growing supply of inexpensive raw materials, like agricultural residues and sawmill by-products, also makes production scalable, especially in developing countries. Improvements in pelletizing technology and supply chain logistics further contribute to the efficiency of production and international trade of biomass pellets. In addition, fiscal incentives like feed-in tariffs, tax incentives, and renewable energy credits are stimulating investments in biomass pellet plant facilities. Increasing concerns regarding energy security and attempts to diversify energy mix in developing economies like India, China, and Brazil are also driving the market growth further. In all, the integration of supportive policy ecosystems, technological advances, and rising environmental awareness is further driving the global biomass pellets market forward.

Case Study on Cost Model of Biomass Pellets Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale biomass pellets manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed biomass pellets manufacturing plant in India. This plant is designed to produce 45,000 tons of biomass pellets annually.

Manufacturing Process: The production of biomass pellets is a multi-step process that aims to transform raw biomass feedstocks—e.g., wood chips, sawdust, agricultural residues, or forest waste into compact, high-energy content pellets ready for combustion. It starts with raw material gathering and preparation where feedstocks are collected and cleaned to eliminate contaminants such as stones, metals, and dust. The biomass is then washed and then size-reduced using chippers and hammer mills that reduce the size of the material into a consistent particle size, usually less than 5 mm, for uniform pellet quality. The material is then dried, an important process to decrease moisture content to the optimal level of around 10–12%. This is done by applying rotary drum dryers or belt dryers, usually driven by biomass waste heat, improving energy efficiency. After drying, the material is transported to the pelletizing machine, where it is pressed under high pressure and heat (usually 80–120°C) through die holes. At this phase, the inherent lignin in the biomass softens and functions as a binder to replace external binders and adds strength to the structure of the pellets. The newly extruded pellets are subsequently cooled by air coolers to solidify and stabilize their composition before they undergo screening to eliminate fines or broken parts. The product pellets are then packaged and stored in dry conditions for shipping or sale. Quality control during the entire process, tracking parameters such as density, moisture content, and calorific value guarantees consistency, durability, and efficient combustion, qualifying biomass pellets as a commercially viable and sustainable energy source.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

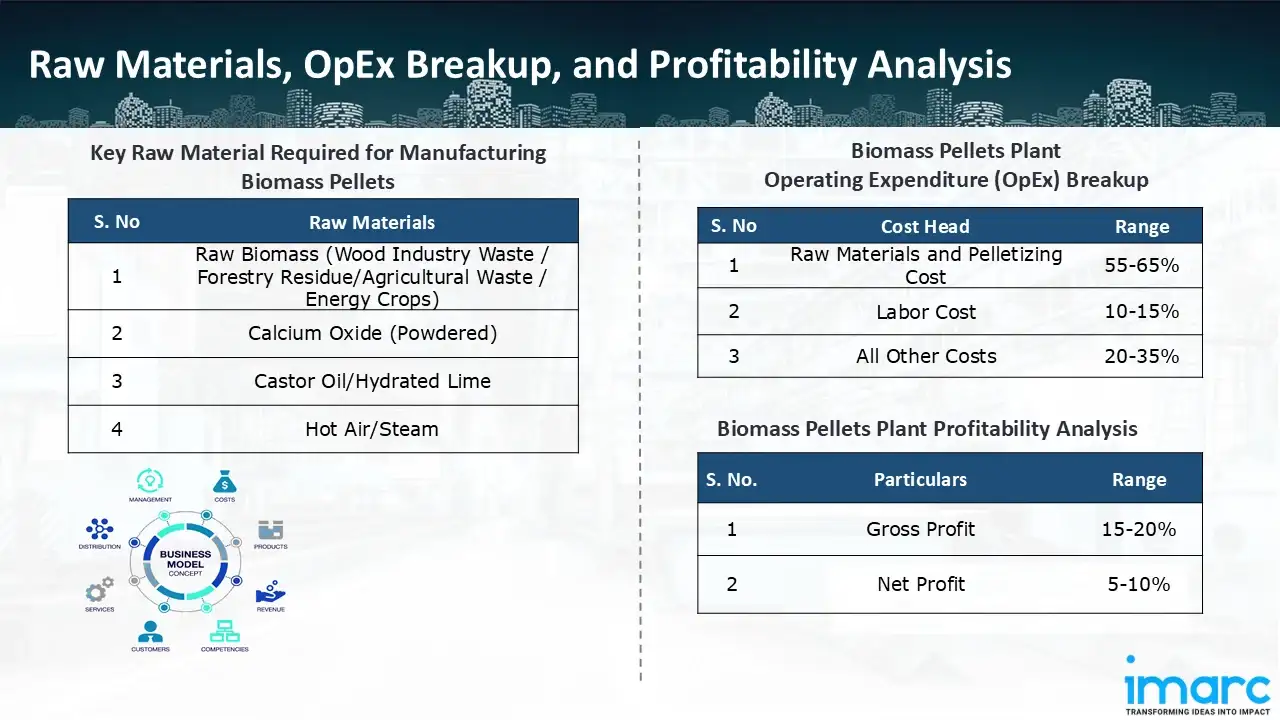

The basic raw materials required for biomass pellets manufacturing include:

- Raw Biomass (Wood Industry Waste / Forestry Residue / Agricultural Waste / Energy Crops)

- Calcium Oxide (Powdered)

- Castor Oil/Hydrated Lime

- Hot Air/Steam

Machineries Required:

- Conveyor Belt

- Storage System

- Rotary Screen

- Screw Conveyor

- Hammer Mill

- Woodchipper

- Grinder

- Screening/Sieving Machine

- Rotary Drum Dryer

- Belt Dryer

- Flash Dryer

- Buffer Bin

- Variable Speed Feeding Screw Conveyor

- Ring Die Pellet Mill

- Flat Die Pellet Mill

- Discharging Belt

- Pellets Surge Bin

- Air Conveying System

- Cyclone Dust Collector

- Counterflow Cooler

- Rotary Cooler

- Vibrating Sieve / Pellet Screener

- Palletizer

- Electronic Control System

- Automatic Bagging Machine

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material and pelletizing cost in a biomass pellets manufacturing plant ranges between 55-65%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the biomass pellets manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 45,000 tons of biomass pellets annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, the United Shipping and Trading Company (USTC) became the sole owner of the business, enhancing its position in the worldwide biomass industry after completing the purchase of all remaining shares in CM Biomass. This action concludes a multi-year investment strategy that started in 2021 when the Danish family-owned company initially acquired a controlling stake in CM Biomass, a prominent global supplier of sustainable biofuels and wood pellets.

- In October 2025, the renewable energy company Drax is working with NGIS, a world leader in geospatial technology, to model and track the carbon stocks of the woods in the United States and Canada from which Drax gets its sustainable biomass. The facility produced more than 5% of the nation's electricity in 2024 by using biomass pellets, mostly from North America.

- In September 2025, Renova Inc., based in Japan, stated that it anticipates resuming operations in October at its 75-megawatt (MW) Omaezakikou Biomass Power Plant. In June, the facility was shut down due to an issue with the auxiliary boiler equipment. Fuelled by wood pellets and palm kernel shells (PKS), the Omaezakikou plant is situated at the Port of Omaezaki in the southernmost region of Shizuoka Prefecture, at the mouth of Suruga Bay.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104