Milk Powder Manufacturing Cost Analysis: White Gold Economics

What is Milk Powder?

Milk powder is a type of dehydrated dairy product, which is manufactured by removing almost all moisture from liquid milk by means of various evaporation and drying techniques. The resultant product is a stable, shelf-friendly powder containing most of the nutritional components of milk, including proteins, lactose, minerals, and fats. Milk powder may be prepared from whole, skimmed, or partially skimmed milk, depending on its intended use. The very low moisture content inhibits microbial growth and spoilage; hence, it becomes more feasible regarding transport, storage, and usage in different formulations. It serves as a versatile ingredient across food, beverage, and industrial sectors where long shelf life and consistent quality are needed.

Key Applications Across Industries:

Milk powder has wide applications across every key food, beverage, nutrition, confectionery, bakery, and industrial food processing segments because of its stability, solubility, and functional properties. In the dairy and beverage industries, it is reconstituted into fluid milk, flavored milk drinks, tea and coffee whiteners, and infant formula. Predictable composition makes it a critical ingredient in baby nutrition, clinical nutrition, and fortified foods, where consistency and safety are paramount.

In the bakery and confectionery industry, milk powder enhances browning, texture, and flavor in products such as cakes, cookies, bread, chocolates, and caramel products. Its emulsifying and water-binding properties improve dough structure and prolong shelf life. In processed food, it finds application in soups, sauces, ready-to-eat meals, and snack coatings since it improves creaminess and enhances protein content.

Milk powder has applications in the ice cream and yogurt industries for enhancing the solids content, improving body and texture, and maintaining quality during freezing or fermentation. Milk powder can be used to enhance processing in meat, providing the benefits of improved binding, moisture retention, and color. Skimmed milk powder can be employed in nutritional supplements and sports nutrition because of its high protein content. Milk powder also finds applications in pharmaceuticals and cosmetics due to its nutrient-rich profile and functional properties apart from its main food applications.

What the Expert Says: Market Overview & Growth Drivers

The global milk powder market reached a value of USD 38.5 Billion in 2025. According to IMARC Group, the market is projected to reach USD 61.3 Billion by 2034, at a projected CAGR of 5.15% during 2026-2034. The global market for milk powder is influenced by demographic trends, changes in consumer behavior, and structural changes within the food-processing and dairy industries. The rising demand for shelf-stable and easily transportable dairy ingredients, especially in regions with a low level of cold-chain infrastructure, accounts for one of the strong drivers in the market. Milk powder has a long shelf life and lightweight form, making it quite practical for use by both manufacturers and consumers in developing markets.

The growth of the infant nutrition industry gives a considerable boost to high-quality skim milk powder and whey derivatives. Increasing birth rates and disposable incomes in certain regions drive up manufacturers' use of milk powder for its safety, consistency, and nutrient density.

The growth of the food processing industries like bakery, confectionery, ready meals, beverages, and dairy alternatives is also a driver for consumption. Milk powder offers functional benefits like improved texture, higher protein levels, and flavor enhancement that make it a key input for product innovation. Globally expanding brands favor milk powder due to standardized quality that assists uniform formulation across markets.

Another major driver is the globalization of dairy trade. Countries that have excess fresh milk production, such as New Zealand, EU nations, and the U.S., export large amounts of milk powder to countries experiencing supply deficits, resulting in a strong international market.

This rising popularity of nutritional supplements, sports nutrition, and protein-enriched foods will further accelerate demand for skim milk powder. Also, emergencies, humanitarian missions, and military supply chains rely on milk powder for its stability and nutrient density, adding resilience to the market. Put together, these drivers underline milk powder’s importance as a multifunctional, trade-friendly, and value-adding dairy ingredient across industries worldwide.

Case Study on Cost Model of Milk Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale milk powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed milk powder manufacturing plant in India. This plant is designed to manufacture 3,000 tons of milk powder annually.

Manufacturing Process: The production of milk powder consists of the removal of water from liquid milk by preserving its nutritive value, functional properties, and shelf stability. Raw milk, collected from various sources, is clarified to remove impurities and sediments by filtration through centrifugal clarifiers. Standardization of the raw milk is done to give the desired level of fat and SNF to produce whole, skim, or semi-skimmed milk powder. After standardization, the milk is heat-treated and undergoes pasteurization (at 72–78°C/15–20 s) to destroy pathogenic microorganisms and inactivate spoilage enzymes. In this stage, the pasteurized milk is sent to the evaporators, where the milk undergoes multi-effect evaporation under vacuum to remove approximately 50–60% of its water content. This concentrates the milk with minimum heat damage. The condensed milk, as it is known at this stage, is preheated and homogenized for proper fat distribution. This enhances powder solubility and texture. The concentrate is fed into a spray dryer, which is the most prevalent method of milk-powder production. Atomization of the concentrate is done by a nozzle or rotary atomizer to fine droplets, which are exposed to a stream of hot air. This results in sudden evaporation of moisture, forming fine dry powder particles falling to the bottom of the drying chamber. In accordance with the product specifications, this powder may further undergo fluidized-bed drying to reduce moisture and enhance particle uniformity. This milk powder is then sieved, cooled, and packaged in moisture-proof bags or containers. It undergoes quality checks for microbiological and nutritional standards, as well as physicochemical standards, before distribution.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

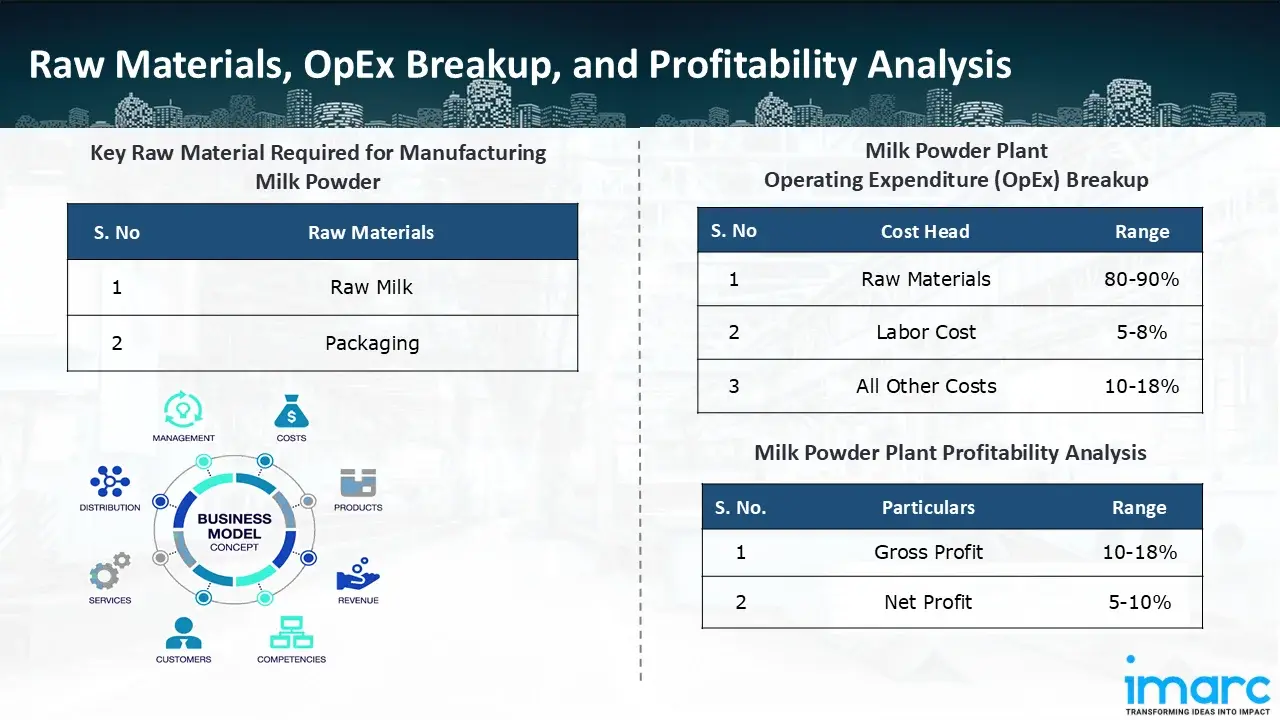

The basic raw materials required for milk powder manufacturing include:

- Raw Milk

- Packaging

Machine Section or Lines Required:

- Reception

- Pasteurization

- Evaporation

- Spray Drying

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in milk powder manufacturing plant ranges between 80-90%, labor cost ranges between 5% to 8%, and all other costs ranges between 10-18% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 10-18%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the milk powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 3,000 tons of milk powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2025, Walmart announced plans to invest $350 million to construct a second dairy processing facility in the US to satisfy the increasing demand from consumers for reasonably priced dairy products.

- In October 2025, PM Modi virtually opens an Indore milk powder facility worth INR 76.5 crore. The mill, which is owned by the Indore Cooperative Milk Union, can make thirty metric tonnes of milk powder every day.

- In July 2025, the German farm and refrigeration technology business GEA Group AG announced that it has signed an agreement with the Algerian government to build an integrated dairy farm and milk powder facility in Algeria. This order is worth between 140 million and 170 million euros. Construction is scheduled to start in early 2026. Production of milk powder is anticipated to start in late 2027, with an ultimate capacity of about 100,000 tonnes annually.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104