Ferrous Sulphate Production Cost Analysis: From Rust to Revenue

What is Ferrous Sulphate?

Ferrous sulphate is an inorganic salt, composed of iron, sulfur, and oxygen, and is mainly known for its pale green or blue-green crystalline appearance. It exists in various hydrated forms, the most common being ferrous sulphate heptahydrate (FeSO4·7H2O), although it is also produced largely as a monohydrate and anhydrous variant, depending on the industrial needs. It is usually manufactured as a by-product of the pickling of steel using sulfuric acid, or it could be produced as a co-product from titanium dioxide pigment manufacture.

Key Applications Across Industries

Ferrous sulphate is essential in many industries because it provides several elements: it is a source of soluble iron, a nutrient, and a reducing agent. In agriculture, it is applied as a soil amendment and micronutrient fertilizer, correcting iron deficiency in plants and preventing chlorosis. Its role in water and wastewater treatment includes being a coagulant and flocculant for effective impurity removal, such as phosphates and suspended solids. Due to high bioavailability and cost effectiveness, ferrous sulphate is generally used as an iron supplement in pharmaceuticals and human nutrition in cases of anemia and iron deficiency disorders. Further applications are found in animal feeding, in pigment production, in textile dyeing, and in cement manufacturing as a colorant or setting regulator. Given the growing standards of environment and industry, ferrous sulphate increasingly finds a favorable position due to its friendlier aspects to nature compared to more toxic iron salts. Ferrous sulphate is widely available, inexpensive to produce, and offers multifunctionality in its chemical properties; hence, it is an indispensable material for agriculture, water management, and industrial chemistry applications around the world.

What the Expert Says: Market Overview & Growth Drivers

The global ferrous sulphate market reached a value of USD 2.02 Billion in 2024. According to IMARC Group, the market is projected to reach USD 2.91 Billion by 2033, at a projected CAGR of 4.1% during 2025-2033. The global ferrous sulphate market is driven by a mix of environmental, industrial, and agricultural dynamics that focus on resource efficiency, waste recovery, and the use of sustainable chemicals. Among these, its increasing application in water and wastewater treatment is one of the major factors driving the demand. With governments and industries setting more strict environmental regulations, ferrous sulphate is increasingly considered an effective coagulant/flocculant in the removal of phosphates and heavy metals due to its non-toxic nature and high efficiency with lower sludge generation than traditional chemicals. Growing urbanization and industrialization in developing regions further heighten the demand for water purification solutions with increased efficiency.

Another significant growth factor is the agricultural sector. There is a high demand for ferrous sulphate as an iron fertilizer and soil conditioner due to micronutrient depletion in the soil and the global need to increase crop yields. It helps avoid iron chlorosis and assists in the better assimilation of nutrients by crops, especially in alkaline soils. In addition, growing demand for animal feed with fortification and nutrient-rich food products widens its application in animal nutrition. Moreover, industrial consumption of ferrous sulphate as a feedstock for pigments, cement, and iron oxide industries continues to see stable demand. It serves as a reducing agent during chemical synthesis and in the removal of chromium from industrial effluents. Besides this, circular economy practices, especially recovery from steel and TiO2 industries, are fostering sustainable production. These, along with the improvements in waste-to-value manufacturing and environmental remediation uses, are collectively shaping the ferrous sulfate market as an enabler of eco-efficient industrial and environmental processes globally.

Case Study on Cost Model of Ferrous Sulphate Manufacturing Plant

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale ferrous sulphate manufacturing plant.

Make Informed Decisions with a Tailored Feasibility Study Request Sample

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ferrous sulphate manufacturing plant in India. This plant is designed to manufacture 10,000 tons of ferrous sulphate annually.

Manufacturing Process: The manufacturing process includes controlled reaction of iron or its compounds with sulfuric acid, purification, crystallization, and drying. The most common method makes use of steel scrap or iron filings as the raw material. Acid dissolution initiates the process, where metallic iron is reacted with diluted sulfuric acid, H2SO4, under controlled temperature and agitation. This step yields an aqueous solution of ferrous sulphate, FeSO4, along with hydrogen gas. The reaction can be represented chemically as follows: Fe + H2SO4 → FeSO4 + H2↑. The solution is filtered after completion of the reaction to remove all the insoluble impurities, which may include rust, carbon residues, and unreacted matter. After filtration, the ferrous sulphate solution is transferred into the crystallization unit, where it undergoes gradual cooling to encourage the nucleation of ferrous sulphate heptahydrate (FeSO4·7H2O) crystals. The crystals are then centrifuged or filtered, washed to remove traces of acid, and dried under controlled conditions, usually at low temperatures, so that the desired hydrated form is preserved. The dried crystals are screened to a uniform particle size and packed for industrial or commercial use. Another production route is the recovery as a coproduct of ferrous sulphate from the manufacture of TiO2, whereby ferrous sulphate is formed during the digestion of ilmenite with sulfuric acid. This by-product is purified and similarly processed by crystallization and drying. In general, the process places much emphasis on chemical efficiency, impurity control, and moisture control to ensure consistency in quality for use in applications such as water treatment, fertilizers, pharmaceuticals, and general industrial chemistry.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

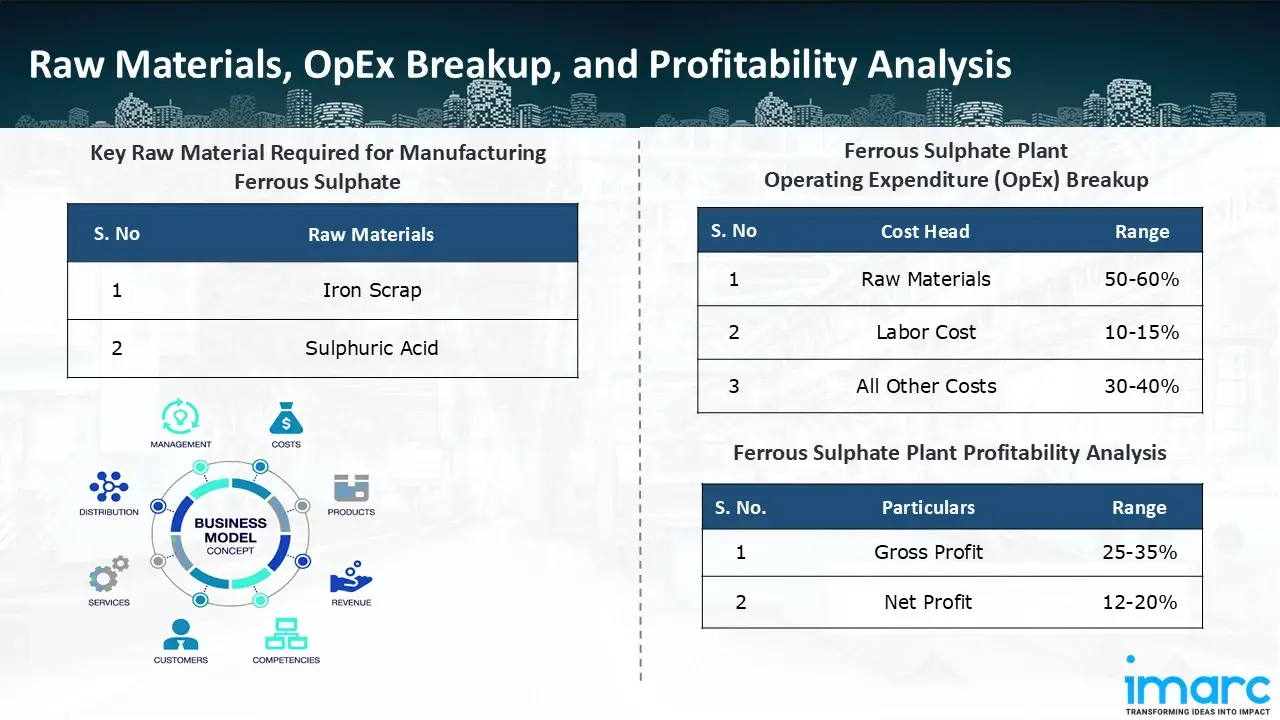

The basic raw materials required for ferrous sulphate manufacturing include:

- Iron Scrap

- Sulphuric Acid

Machine Section or Lines Required:

- Reaction Vessel

- Crystallizer

- Dryer

- Grinder

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in ferrous sulphate manufacturing plant ranges between 50-60%, labor cost ranges between 10% to 15%, and all other costs ranges between 30-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-35%, and net profit lie between the range of 12-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact

Our financial model for the ferrous sulphate manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 10,000 tons of ferrous sulphate annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments

- In May 2025, Russian Vitriol Company is the first in Russia to begin manufacturing ferrous sulphate monohydrate at a facility in the Blagoveschensk priority development area in its native region of Bashkortostan.

- In February 2025, the iron sulphate coagulant division of Thatcher Group in the US East Coast has been fully acquired by Kemira. Certain clients and company assets are involved in the deal. Since Kemira will serve the new clients from its current manufacturing facilities, no staff will relocate to Kemira as a result of the deal. The acquired company generates less than US$ 10 million in revenue annually. With its headquarters located in Salt Lake City, Thatcher Company, Inc. is a multifaceted chemical manufacturer and distributor.

Why Choose IMARC

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104