Millet Processing Cost Analysis: Tiny Grains, Big Margins

What is Millet?

Millet represents a group of small-seeded cereals, primarily from the Poaceae family, which are grown as staple foods for thousands of years in Asia and Africa and, increasingly, in other parts of the world. These cereals include pearl millet, foxtail millet, finger millet, proso millet, barnyard millet, and little millet. Due to their resilience, millets grow well under arid, semi-arid conditions, and in low-fertility soil. Millets are inherently gluten-free and rich in dietary fiber, minerals, antioxidants, and slowly digestible carbohydrates, hence nutritionally superior to most conventional cereals. Because of their adaptability, climate tolerance, and ability to grow with minimal inputs, they hold particular importance in sustainable agriculture and food security.

Key Applications Across Industries

Millets have a wide range of applications in food, beverage, industrial, and animal feed sectors. Being a food grain, millets are consumed in their traditional forms as porridges, flatbreads, steamed dishes, fermented foods, and gruels in several cultures. With improved health awareness, millets are increasingly being value-added into ready-to-cook and ready-to-eat products, including flakes, flour blends, pasta, noodles, cookies, breakfast cereals, snack bars, and bakery items. Their gluten-free nature makes them valuable for the specialty foods market, especially for consumers with celiac disease or gluten sensitivity. Finger millet (ragi) is commonly used in baby foods due to its high calcium content, while foxtail and little millets are gaining traction in diabetic-friendly food formulations because of their low glycemic index.

In beverages, millets are used to develop health drinks, traditional fermented beverages, plant-based milk alternatives, and craft beers. Besides, they are important in animal feed, especially in poultry and livestock nutrition, as they offer a balanced amino acid profile that aids in growth and immunity. Millets are also used in malt, extruded snacks, and fortified blends as value-added products. Other industrial applications include biodegradable packaging material development and brewing. Their adaptability to processing technologies like extrusion, milling, malting, and puffing makes them suitable for a wide range of modern food innovations.

What the Expert Says: Market Overview & Growth Drivers

The global millet market reached a value of USD 14.0 Billion in 2025. According to IMARC Group, the market is projected to reach USD 19.7 Billion by 2034, at a projected CAGR of 3.78% during 2026-2034. The global millet market is growing strongly, as nutritional demand, climate resilience, policy support, and changes in food habits all act together. One of the most significant drivers is increasing health and wellness awareness, with demand by consumers for high-fiber, protein-rich, gluten-free options to traditional cereals. The nutritional advantages of millets are their low glycemic index, high mineral content, and antioxidant properties, all of which meet global dietary trends that favor functional foods and preventive nutrition. This assumes much significance as lifestyle-related diseases like diabetes, obesity, and cardiovascular issues continue to rise globally.

Climate change is another key catalyst. Millets use less water, less input, and are heat- and drought-tolerant, hence indispensable for sustainable agriculture and food-security strategies, especially in regions whose rainfall has become erratic or whose soil fertility has declined. Subsidies, research programs, awareness campaigns, and other promotional efforts of governments and international organizations, which include initiatives such as the UN’s “International Year of Millets,” accelerate farm-level adoption and investments in industrial-scale processing.

Interest among consumers in natural, traditional, and clean-label foods is also boosting demand for millets. Improvements in processing technologies have led to a range of innovative millet-based packaged foods, increasing their availability through modern retail channels. The rise of plant-based, vegan, and specialty diet segments opens further prospects for millet-based products.

Globalization of cuisines and the rise of e-commerce further extend the market reach, making it easier for millet producers and brands to reach out to international markets. These factors, including health trends, sustainable needs, technological advances, and supportive policy, put together, are shaping strong long-term growth for the global millet market.

Case Study on Cost Model of Millet Processing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale millet processing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed millet processing plant in India. This plant is designed to manufacture 5,000 tons of millet annually.

Processing Flow: The processing of millets involves several steps designed to remove inedible portions, improve texture, enhance nutritional availability, and convert raw grains into value-added products. Cleaning starts the processing, where harvested millets are passed through sieves, aspirators, and gravity separators for the removal of dust, stones, chaff, and foreign materials. The cleaned grains then undergo dehulling or decortication, a crucial step; millet grains have very tight outer husks that must be removed for human consumption. Dehulling is normally done by abrasive dehullers, emery rollers, and centrifugal machines. After dehulling, depending on the available grain and intended end use, grains may either be polished or graded. In the case of flours, the grains are milled using hammer mills, pin mills, or stone grinders to accomplish any desired particle size. Whole or broken millets may be further processed using techniques like puffing, roasting, flaking, malting, or extrusion to produce breakfast cereals, snacks, instant mixes, and beverages. Malting, normally recommended for finger millet and sorghum, consists of soaking, germination, and drying, which, besides improving digestibility, enhances the bioavailability of nutrients. Processed millets for industrial-scale applications are packed using moisture-proof, airtight packaging to maintain their shelf life. Quality checks such as moisture measurement, microbial analysis, and uniformity of grain are done during the entire process. Overall, the processing of millet transforms hardy raw grains into versatile ingredients suitable for traditional foods, modern convenience products, and nutritionally enriched formulations.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

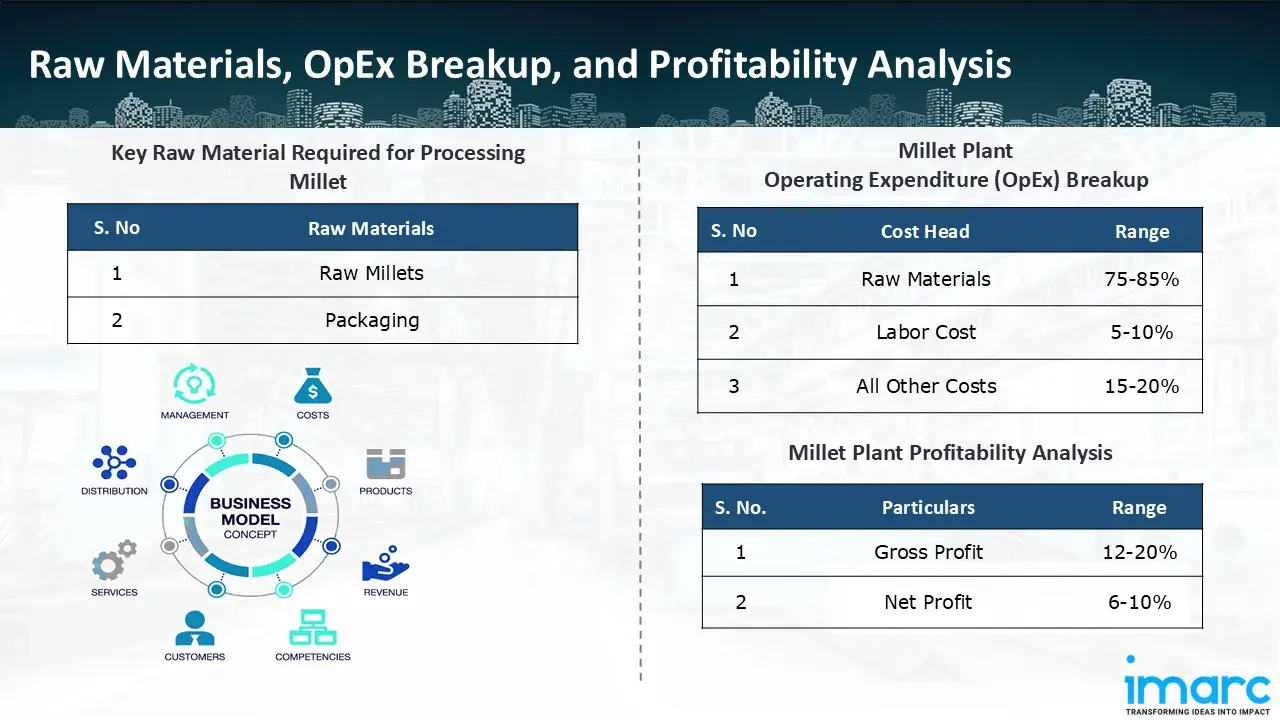

The basic raw materials required for millet processing include:

- Raw Millets

- Packaging

Machine Section or Lines Required:

- Cleaning

- Dehulling

- Polishing

- Grading

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a processing plant effectively. OpEx in a processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in millet processing plant ranges between 75-85%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 12-20%, and net profit lie between the range of 6-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the millet processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, processing, capital expenditure, and operational expenses. By addressing the specific requirements of processing 5,000 tons of millet annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale processing ventures.

Latest News and Developments:

- In October 2025, Nav Bharat Jagriti Kendra (NBJK) under the Murhu Nari Shakti Kisan Producer Company Limited (FPO), has successfully established a solar-powered finger millet processing unit in partnership with Collectives for Integrated Livelihood Initiatives (CInI)-Tata Trusts, with assistance from World Resources Institute India (WRI India) and IKEA.

- In September 2025, PepsiCo India entered into the millet-based snack market with Kurkure Jowar Puffs, which retail for Rs 10 and Rs 20. The new product will be accessible through prominent e-commerce platforms, quick-commerce apps, and traditional and modern retail throughout North, West, and East India.

- In November 2024, the Ramoji Group started Sabala Millets, an initiative to market millet-based goods designed for consumers who are health-conscious. In its initial phase, the business introduced 45 products, including cookies, health bars, munchies, noodles, and local millet-based khichdi.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the processing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish processing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104