Tennis Ball Manufacturing Cost Analysis: Pressure, Precision & Profitability

_11zon.webp)

What is Tennis Ball?

Tennis ball production is the process of making standardized balls for the game of tennis. The process involves making balls with specific performance and bounce features. A tennis ball is made up of a hollow rubber core that is filled with pressurized air. The core is then covered with a woven felt material. The production process involves making the balls with specific material control, pressure, weight, and texture to ensure that they have specific play features. The balls are manufactured according to international sports standards since even the slightest variation can affect their performance.

Key Applications Across Industries:

The primary application of tennis balls is in the game of tennis, where they are used in recreational, amateur, professional, and tournament-level games. Tennis balls of different quality are made for use on different surfaces like hard courts, clay courts, and grass courts, each of which demands a different felt density and rate of wear. Professional tennis games demand balls with a very consistent bounce, speed, and longevity, while recreational balls emphasize cost-effectiveness and longevity.

Apart from being used in competitive tennis games, tennis balls are used in training and teaching settings. Practice balls are made for repeated use, sometimes with reduced air pressure or increased felt thickness to increase longevity and decrease cost. Pressure less balls are used in tennis academies and beginner classes because of their ability to retain bounce for a longer period of time.

Apart from their use in sports, tennis balls are used in other applications as well. They are often used in other recreational games, physical therapy, and fitness training to enhance hand-eye coordination, grip strength, and physical therapy outcomes. In industrial and domestic applications, tennis balls are sometimes used as vibration dampeners, noise reducers, or protective covers on equipment and furniture.

In an academic environment, tennis balls are utilized for motor skill training and physical education classes. The fact that they are light, soft, and have a consistent bounce makes them ideal for use in an academic setting. These varied uses of tennis balls increase demand beyond the realm of professional sports.

What the Expert Says: Market Overview & Growth Drivers

The global tennis ball market reached a value of USD 788.0 Million in 2024. According to IMARC Group, the market is projected to reach USD 1,235.3 Million by 2033, at a projected CAGR of 5.1% during 2025-2033.

The global tennis ball production market is fueled by a combination of sports participation trends, institutional demand, and product replacement cycles. Among the most important factors is the popularity of tennis as a recreational and competitive sport. Tennis is played by people of all ages and skill levels, thus ensuring a constant demand for balls in tennis clubs, academies, schools, and public sports facilities. Unlike sports equipment, tennis balls have a short usable life, particularly pressurized balls, thus ensuring a constant replacement demand.

Investments in sports infrastructure also fuel the market. Tennis court construction, training facilities, and community sports initiatives ensure a constant demand for tennis balls for practice and play. Youth development initiatives and amateur sports tournaments also fuel the demand.

Professional tennis leagues and sports tournaments are important demand pullers. Major sports events set performance standards and shape consumer preferences, thus pressuring manufacturers to ensure high quality and make incremental improvements. Sponsorships and partnerships also fuel brand-driven demand in retail markets.

Another significant factor is diversification in product lines. The manufacturers have developed balls designed for beginners, children, high-altitude conditions, and long-lasting balls, thus increasing the customer base. Also, the increasing focus on physical fitness and outdoor activities helps to sustain interest in tennis as a lifetime sport.

On the production side, advancements in manufacturing efficiency and material science enable manufacturers to increase production volume while sustaining quality. All these factors ensure a steady global demand for tennis balls irrespective of economic cycles.

Case Study on Cost Model of Tennis Ball Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale tennis ball manufacturing plant.

(Image to be provided by the SEO team and name to be changed in that)

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed tennis ball manufacturing plant in India. This plant is designed to manufacture 2 million pieces of tennis ball annually.

Manufacturing Process: The production process of tennis balls is a precision-based process aimed at ensuring that the balls have a consistent bounce, durability, and playability. The process starts with the production of natural and synthetic rubber compounds, which are blended in a controlled manner to ensure the attainment of the necessary elasticity and strength. The rubber compound is then shaped into two hemispherical shells through a compression molding process involving heat and pressure.

The rubber shells are then combined using an adhesive to form a hollow core. At this point, the core is either left unpressurized (in the case of pressureless balls) or pressurized with air or nitrogen to attain the necessary internal pressure. The bonded cores are then vulcanized, which is a heat treatment process aimed at stabilizing the rubber material and fixing the pressure.

Simultaneously with the production of the core, the felt fabric is produced through a process involving the blending of wool and synthetic materials, weaving them into sheets, and dyeing them in the required yellow color or other approved colors. The felt is then cut into exact dumbbell-shaped pieces to fit the ball evenly.

In the assembly process, two felt parts are attached to each rubber core and then exposed to heat and pressure to ensure a strong bond between the felt and to flatten the seams. The balls undergo finishing and conditioning, where the texture, seams, and roundness are improved.

Finally, the tennis balls are inspected for quality, which involves testing their bounce, weight, compression, and appearance. The approved balls are then packed, usually in pressurized cans to preserve their performance until they are used.

Get a Tailored Feasibility Report for Your Project Request Sample

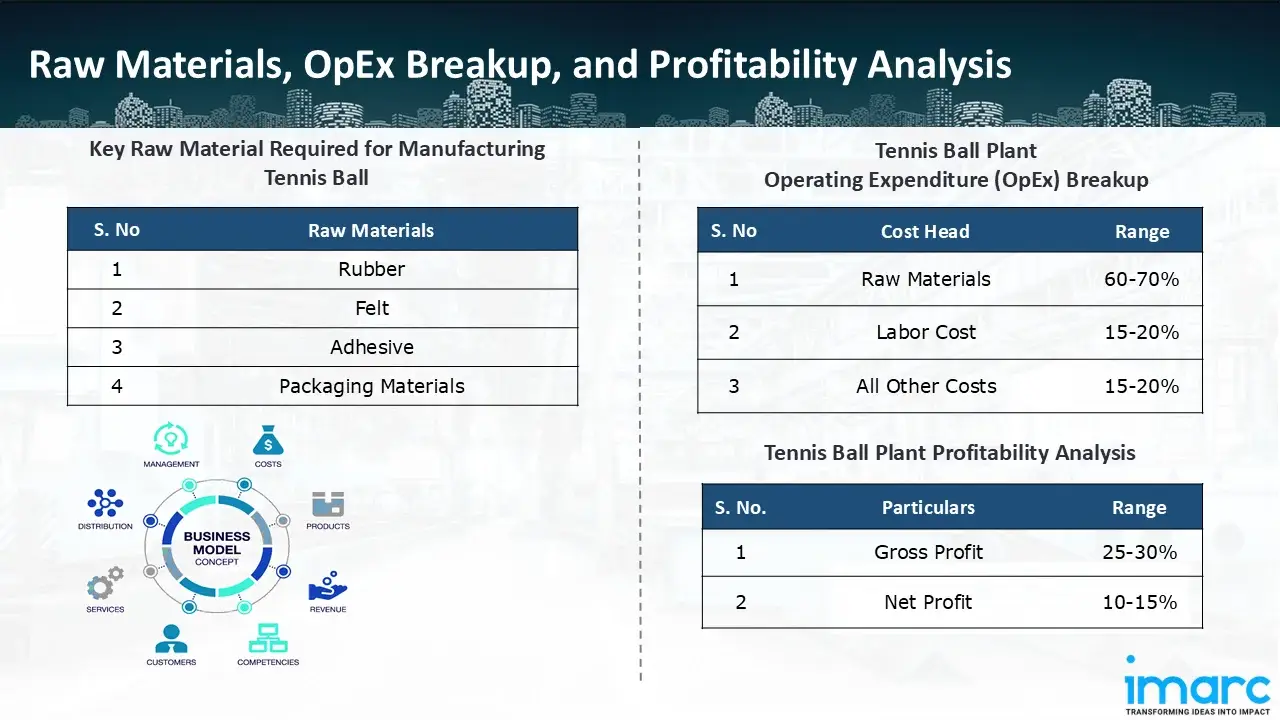

Raw Material Required:

The basic raw materials required for tennis ball manufacturing include:

- Rubber

- Felt

- Adhesive

- Packaging Materials

Machine Section or Lines Required:

- Rubber Compounding

- Molding

- Felt Cutting

- Bonding

- Pressing

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in tennis ball manufacturing plant ranges between 60-70%, labor cost ranges between 15% to 20%, and all other costs ranges between 15-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-30%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the tennis ball manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2 million pieces of tennis ball annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In August 2025, Noé Chouraqui, a graduate of Central Saint Martins, created Point, a 3D-printed substitute for conventional tennis balls composed of recyclable, bio-based filament. Point balls have the same classic neon-yellow, ringed appearance as standard tennis balls, but instead of the customary hollow rubber core wrapped in felt, they are made of PLA-HR, a 3D-printed filament produced from plants.

- In August 2025, Head Sport's announced its new Panabo factory in Davao del Norte which is set to become a major global production hub with the production capacity of 14 million dozen tennis balls a year. When the plant reaches full capacity, it will support the company's global supply chain and employ nearly 700 people.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104