Fiberglass Manufacturing Cost Model: From Silica to Strength

What is Fiberglass?

Fiberglass, also known as glass fiber, is a composite material manufactured by weaving, chopping, or layering minute strands of glass into strong yet lightweight and durable products. It is made by melting silica sand, limestone, soda ash, and other raw materials together at very high temperatures-around 1,700°C-through which molten glass is obtained. It is extruded through fine nozzles to create continuous filaments, then combined into mats, fabrics, or roving later on, according to use. The resulting material is characterized by high tensile strength, resistance to chemicals, low weight, and excellent heat and electrical insulation properties.

Key Applications Across Industries:

Industries that widely make use of this product include construction, automotive, aerospace, marine, renewable energy, and electronics, while its usage often concerns its role as reinforcement in composites, such as fiberglass-reinforced plastic. Common applications range from composite manufacturing, such as combining fiberglass with polyester, epoxy, or vinyl ester resins to make pipes, tanks, panels, and bodies of vehicles, to serving in the construction industry due to its corrosion resistance and dimensional stability in roofing materials, insulation, wall reinforcement, and rebar replacements. In applications involving transportation, it reduces the weight of the vehicle to improve fuel economy while maintaining structural integrity. In the energy sector, wind turbine blades and solar panel parts depend on fiberglass. A versatile, economical, and high-performance material, especially in harsh environmental conditions, fiberglass is a necessary material in modern engineering and sustainable design, enabling developments to meet strength, lightness, and cost-efficiency requirements.

What the Expert Says: Market Overview & Growth Drivers

The global fiberglass market reached a value of USD 12.79 Billion in 2024. According to IMARC Group, the market is projected to reach USD 17.8 Billion by 2033, at a projected CAGR of 3.7% during 2025-2033. The driving factors for the global fiberglass market include technological advancement, infrastructure development, environmental sustainability, and industrial diversification. The key drivers of growth involve increasing demand from various industries for lightweight and high-strength materials in the automotive, aerospace, and wind energy sectors. In addition, manufacturers looking to improve efficiency without sacrificing durability are replacing conventional metals like steel and aluminum with fiberglass composites.

In construction, the rate of urbanization and infrastructure renovation has increased consumption of fiberglass-based products, such as insulation, roofing, panels, and reinforcing bars, due to their resistance to corrosion, heat, and moisture. Other significant drivers are the growing renewable energy sector, more so the global installation of wind farms. The specific mixture of strength and flexibility, along with low weight, makes fiberglass the go-to material for the manufacture of wind turbine blades and nacelles, fostering the increasing shift toward clean energy. Similarly, in automotive manufacturing, tighter emission standards are pushing the use of lightweight composites for fuel economy and extended range in electric vehicles. The marine and aerospace industries also use fiberglass for parts that can resist temperature fluctuation, vibrations, and chemical exposure. Environmental sustainability with fiberglass is achieved by contributing to energy efficiency in buildings through better thermal insulation material that reduces the heating and cooling loads. This is further supported by technology leading to better recycling and the introduction of bio-based resins. In addition, continuous improvement in filament technology, resin chemistry, and fabrication methods is increasing the usability of fiberglass in a range of emerging applications, including smart infrastructure, hydrogen storage tanks, and high-speed rail systems. All these factors together make fiberglass a critical material for the transformation to lightweight, energy-efficient, and sustainable industrial solutions across the world.

Case Study on Cost Model of Fiberglass Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale fiberglass manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed fiberglass manufacturing plant in India. This plant is designed to manufacture 30,000 tons of fiberglass annually.

Manufacturing Process: The production of fiberglass is a multi-stage process in manufacturing, carefully controlled to turn raw minerals into fine, durable glass filaments for a wide array of industrial and commercial uses. It starts with the selection and batching of the raw materials-silica sand, limestone, soda ash, alumina, and borax-which are mixed together in precise proportions. The mixture is fed into the furnace, where at about 1,600 -1,700°C, it forms molten glass. The molten glass, while in the furnace, is refined continuously by removing bubbles and impurities to maintain uniform viscosity suitable for fiber formation. Once homogenized, the molten glass is transferred to a platinum-rhodium bushing, a specialized device with many tiny orifices. Through this bushing, the molten glass is extruded into ultra-fine filaments, often as thin as one-tenth the diameter of a human hair. As these filaments emerge, they are rapidly cooled and coated with a chemical sizing agent that enhances adhesion, flexibility, and compatibility with resins during composite manufacturing. The sizing process is very important, as it will determine the final product's mechanical and chemical properties. The next stage in the process, fiber collection and forming, represents the gathering of continuous filaments into strands, rovings, or chopped fibers, depending on their application. Such fibers can be further wound onto spools, interwoven in mats or fabrics, or chopped to predetermined lengths for reinforcement applications. Finished products undergo curing and drying, with careful quality checking to ensure consistent diameter and tensile strength, as well as uniformity. It is by this complex and energy-consuming method that fiberglass materials achieve the combination of lightweight strength, heat resistance, and corrosion resistance that makes them invaluable in a myriad of applications, including construction, automotive, marine, and renewable energy.

Raw Material Required:

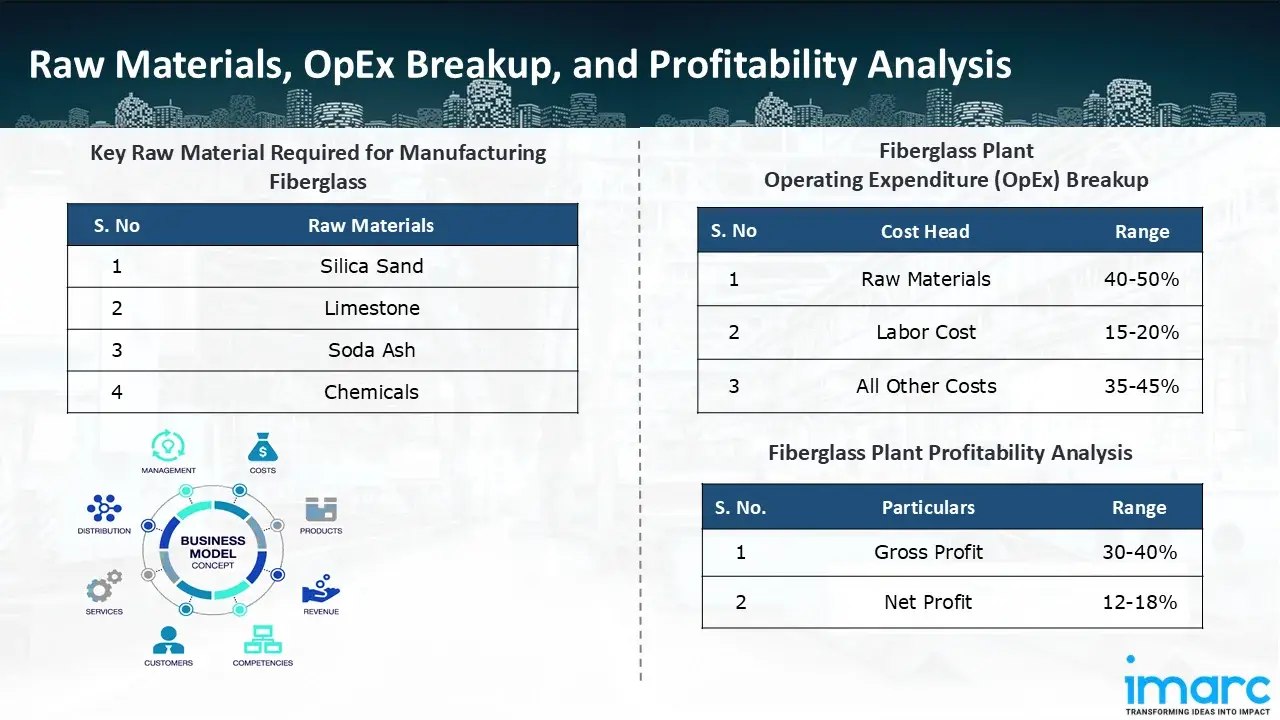

The basic raw materials required for fiberglass manufacturing include:

- Silica Sand

- Limestone

- Soda Ash

- Chemicals

Machine Section or Lines Required:

- Melting Furnace

- Fiberizing

- Binder Spray

- Curing Oven

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in fiberglass manufacturing plant ranges between 40-50%, labor cost ranges between 15% to 20%, and all other costs ranges between 35-45% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the fiberglass manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 30,000 tons of fiberglass annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In March 2025, the first production line of Taishan Fibreglass (Taiyuan) Co., Ltd. was put into service in Taiyuan, in the Shanxi province of northeast China.

- In February 2025, the glass reinforcements division of Owens Corning will be sold to Praana Group (through its subsidiaries) for an enterprise value of US$ 755,000,000, according to a contractual agreement between Owens Corning and Praana Group.

- In February 2025, global building and speciality goods producer Johns Manville (JM) announced the construction of a new Climate Pro® blowing wool production line in Winder, Georgia.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104