Australia’s Bioplastics Industry Driven by Consumer Demand and Government Sustainability Goals

Introduction:

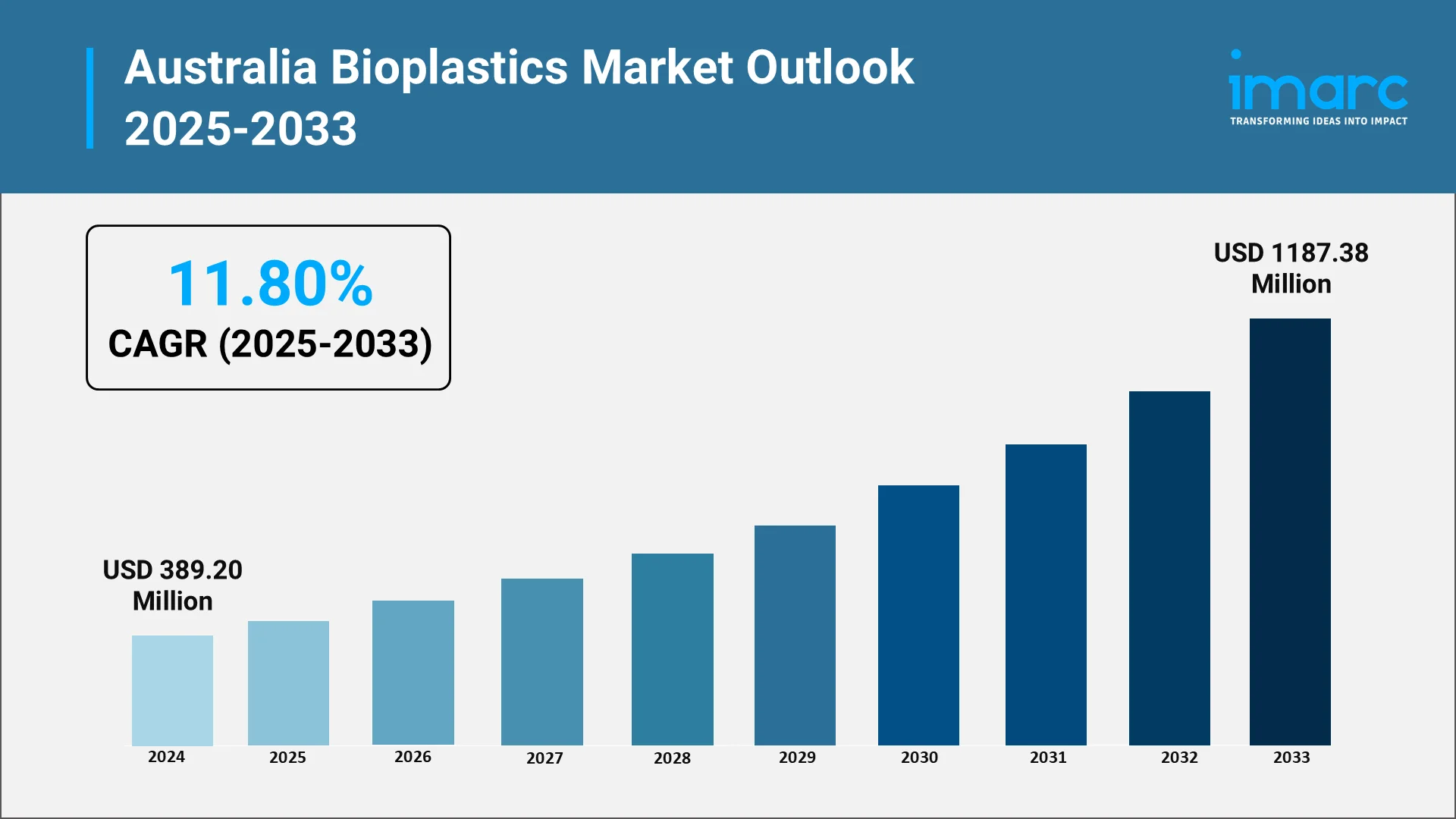

The Australia bioplastics industry is experiencing unprecedented growth, driven by intensifying consumer demand for sustainable alternatives and robust government sustainability initiatives. The Australia bioplastics market size reached USD 389.20 Million in 2024. Looking forward, the market is projected to reach USD 1187.38 Million by 2033, exhibiting a growth rate (CAGR) of 11.80% during 2025-2033. The market is driven by government regulations and sustainable packaging policies. This remarkable expansion reflects a fundamental shift in how businesses and consumers approach packaging and product development across multiple sectors including food service, agriculture, and consumer goods.

Australia’s dedication to environmental sustainability has positioned the nation as a leader in the global bioplastics movement. While bioplastics currently represent a small fraction of the country’s plastic use, there is significant potential to expand commercial applications while mitigating environmental impact. The Australia plastics and rubber market is progressively shifting toward sustainable alternatives, driven by the need to address the environmental footprint of traditional plastics. Advancements in biotechnology, artificial intelligence (AI), and eco-conscious manufacturing are fostering innovation across the Australian plastic caps and closures, plastic furniture, and plastic recycling markets. As regulations become more stringent and consumer awareness grows, Australian companies increasingly view bioplastics as integral to their environmental, social, and governance (ESG) initiatives, reflecting a broader commitment to sustainability and responsible production.

Explore in-depth findings for this market, Request Sample

Role of AI, Impact, and Benefits in the Australian Bioplastics Industry:

Artificial intelligence (AI) is transforming Australia’s bioplastics market by improving production efficiency, strengthening quality control, and accelerating the discovery of sustainable materials. Machine learning (ML) enables companies to predict bioplastic properties and identify PHA-based alternatives with performance comparable to conventional plastics.

- Enhanced Production Efficiency: AI-powered systems are transforming manufacturing operations across Australia's bioplastics sector. AI technology plays a pivotal role at Ecopha, enhancing everything from production efficiency to quality control and market trend analysis. This integration ensures that its processes remain at the cutting edge of bioplastics technology, providing our clients with superior, sustainable products.

- Quality Control and Consistency: The implementation of AI-driven quality management systems has significantly improved product consistency in Australian bioplastics manufacturing. Gartner predicts that by 2025, 50% of manufacturers in the Australia bioplastics industry will use AI-driven quality control, ensuring defect-free, biodegradable products while supporting consumer demand and government sustainability goals.

- Material Innovation and Discovery: AI-driven multitask deep neural networks enable researchers to predict bioplastic properties and identify high-performing PHA-based materials. This accelerates formulation timelines from years to months, empowering Australian companies to rapidly develop innovative, sustainable products that meet regulatory standards.

- Predictive Analytics for Supply Chain Optimization: AI algorithms analyze market trends, weather patterns, and agricultural data to optimize raw material sourcing and inventory management. This predictive capability ensures steady supply chains for bioplastic production while minimizing waste and reducing costs across the Australia plastics and rubber market.

Government Initiatives and Support in Australian Bioplastics Industry:

The Australian government has demonstrated unwavering commitment to fostering the bioplastics industry through comprehensive policy frameworks and substantial financial investments. These initiatives align with national sustainability goals and international environmental commitments.

- National Policy Framework: The Bioplastics Innovation Hub aligns with CSIRO's aim of reducing plastic waste entering the Australian environment by 80% by 2030. This initiative advances Australia’s commitment to the UN Global Treaty and the National Plastics Plan, promoting recyclable and biodegradable materials and fostering favorable conditions for bioplastic adoption across multiple sectors.

- Strategic Investment Programs: In September 2024, the Australian Government launched the Bioplastics Innovation Hub in Perth, backed by an AUD 8 Million investment, aiming to accelerate the development of compostable bioplastics. This landmark investment demonstrates the government's commitment to positioning Australia as a global leader in sustainable packaging technologies.

- Regulatory Support and Standards Development: State and federal governments have implemented stringent policies to reduce plastic waste, including bans on single-use plastics and mandates for sustainable packaging. Several states have prohibited single-use plastic bags, prompting retailers to adopt bioplastic options. These regulatory measures create consistent market demand encouraging innovation in the Australia plastic caps and closure market and related sectors.

- Research and Development Partnerships: CSIRO and Murdoch University launched the Bioplastics Innovation Hub in September 2024 to advance compostable, bio-derived packaging that fully breaks down in compost, land and water. The collaboration will support industry with new manufacturing capabilities, boost Australia’s green plastic economy and train future experts to help cut plastic waste nationwide.

- Infrastructure Development Support: The government has identified waste recycling as requiring significant investment and created a $250 million recycling modernization fund to foster innovation and improve local recycling infrastructure. This comprehensive approach addresses end-of-life management challenges while building the circular economy framework necessary for bioplastics success.

Top Companies in the Australian Bioplastics Industry:

Australia's bioplastics sector features dynamic companies leading innovation in sustainable materials development and commercialization. These organizations are driving industry growth through technological advancement and strategic partnerships.

- Ecopha Biotechnology: Founded in Malaysia in 2008 and expanding to Australia in 2013, Ecopha specializes in PHA production, converting food waste into compostable packaging and water bottles, and serves as the bioplastics innovation hub’s first industry partner.

Innovation: Ecopha combines advanced fermentation and proprietary processing to produce fully biodegradable bioplastics, supporting packaging, agriculture, and consumer goods sectors, and driving transformation in the Australia plastic furniture market.

- BioPak Australia: BioPak leads Australia’s compostable food service packaging sector, offering FSC™ certified, plant-based products including cups, containers, and cutlery, designed for circular economy compatibility and promoting sustainable practices across the foodservice industry.

Initiatives: Beyond products, BioPak advances consumer education and infrastructure through its Compost Connect program, ensuring effective composting solutions and fostering adoption of sustainable packaging across Australia.

- Plantic Technologies: Plantic Technologies develops biodegradable plastics from renewable sources, producing high-performance films suitable for food packaging and providing organic alternatives to conventional plastics through proprietary technology.

- Terra Sol and EcoPHA Partnership: The collaboration between Terra Sol and EcoPHA combines scientific innovation and commercial expertise to deliver scalable, compostable bioplastic solutions, setting global standards for sustainable packaging. According to sources, in March 2025, Ecopha Biotech became the first company to produce biodegradable PHA bioplastics from pongamia oil, offering a sustainable, non-food-based alternative and supporting carbon credit initiatives in Australia.

- CSIRO and Research Institutions: CSIRO and Murdoch University drive bioplastic innovation through the Bioplastics Innovation Hub, developing fully compostable materials for land, water, and compost, supporting Australia’s leadership in sustainable packaging and the plastic recycling market.

Opportunities and Challenges in the Australian Bioplastics Industry:

The Australian bioplastics industry presents significant opportunities for growth and innovation, balanced by complex challenges that require strategic solutions and stakeholder collaboration.

Market Opportunities:

- Expanding application sectors: Bioplastics are increasingly replacing conventional plastics in horticulture, agriculture, and biomedicine, such as mulch films. This versatility opens opportunities across multiple industries, including the Australia plastic caps and closure market, with agricultural applications driving substantial growth.

- Consumer demand and premium positioning: Rising environmental awareness among Australian consumers enhances premium positioning for bioplastics. Companies can charge higher prices for sustainable products while fostering brand loyalty, particularly benefiting the Australia plastic furniture market as eco-friendly home and office furnishings gain popularity.

- Export potential: Australia’s expertise in bioplastics and clean manufacturing strengthens its export prospects. Increasing global demand for sustainable packaging provides opportunities for Australian companies to expand internationally, boosting the national economy and reinforcing the country’s reputation as a leader in eco-friendly materials.

Industry Challenges:

- Infrastructure and processing capacity constraints: Bioplastics are greatly hindered from growth by low processing capacity and infrastructure. They are not generally accepted by most of the available waste collection streams, and contamination and inefficiency result from the dearth of specialized composting and recycling facilities.

- Consumer education and disposal confusion: Australian consumers are uncertain about bioplastic disposal, with products ending up polluting recycling or being sent to landfills. Ambiguous labeling and mixed-up practices prevent effective use, calling for education programs and uniform disposal instructions for enhanced bioplastic uptake.

- Cost competitiveness: High production costs restrict bioplastics adoption in Australia, with most products sourced from Thailand and Brazil. It is still more expensive than traditional plastics, requiring technology innovations, enhanced manufacturing efficiency, and scaling to attain cost-competitive pricing and broader adoption.

- Standards for quality and performance: Mixed-material packages, including blends of paper and bioplastics, tend to hinder recyclability or composting elsewhere in the world outside of South Australia. Complicated designs complicate end-of-life treatment, necessitating industry players to create standards that weigh product performance against circularity and sustainability objectives.

- Regulatory fragmentation: Uneven regulations within Australian states and territories pose difficulties for consumers and manufacturers. Coordinated standards, harmonized policies, and unified directives are needed to support industry development, ensure environmental effectiveness, and streamline bioplastic manufacturing, application, and disposal nationwide.

Future Outlook: Australia Bioplastics Industry

The future of Australia's bioplastics industry appears exceptionally promising, with technological breakthroughs, policy support, and market dynamics converging to drive sustainable growth and innovation.

- Technological Innovation Leadership: Australia is advancing the development of fully compostable, bio-derived packaging, including sprays, films, bottles, caps, and wrappers. Research institutions and innovative companies are creating next-generation bioplastics that overcome performance limitations while ensuring environmental sustainability.

- Infrastructure Development: The growth of Australia’s bioplastics market is supported by dedicated waste management infrastructure. Over twenty certified compost facilities in Australia and New Zealand accept bioplastic packaging, and continued investment will enhance processing capacity, support industry scaling, and strengthen consumer confidence in sustainable bioplastic products.

- Integration with Circular Economy: Bioplastics play a pivotal role in Australia’s circular economy, enabling decoupling of economic growth from resource depletion. Their integration supports sustainable value chains, minimizes environmental impact, and positions the bioplastics sector as an essential component of a resource-efficient, innovative economy.

- International Competitiveness: Australia’s strong focus on research, sustainable manufacturing, and AI integration enhances the global competitiveness of its bioplastics industry. High-quality products and robust regulatory frameworks provide the country with strategic advantages, enabling leadership in international bioplastics exports and sustainable materials markets.

- Policy Evolution and Support: Government initiatives, including research funding, infrastructure development, and favorable regulations, continue to strengthen the bioplastics sector. Evolving policies address current industry challenges, promote innovation, and create opportunities for sustainable growth and broader adoption of bioplastic solutions.

- Supply Chain Localization: Australia’s bioplastics industry currently depends on imported raw materials, but local resources such as sugarcane, corn sugar, and starches are increasingly utilized. Expanding domestic supply chains will reduce costs, lower environmental impact, and improve resilience across the bioplastics sector. According to reports, in March 2025 life cycle assessment revealed that PLA production from cane-sugar exhibits a lower carbon footprint and energy consumption compared to microalgal biomass, highlighting feedstock choice as critical for sustainable bioplastic production.

Conclusion:

The Australia bioplastics industry is experiencing robust growth, driven by government sustainability initiatives, rising consumer demand, and technological advancements. Companies are leveraging AI, biotechnology, and eco-conscious manufacturing to enhance production efficiency, quality control, and material innovation. Strategic partnerships, research collaborations, and infrastructure investments are addressing challenges related to processing, disposal, cost competitiveness, and regulatory fragmentation, enabling expansion across sectors such as packaging, agriculture, and consumer goods. Increasing global demand and export opportunities further position Australia as a leader in sustainable materials. By integrating bioplastics into circular economy frameworks, the industry is fostering long-term environmental and economic benefits, ensuring resilience, competitiveness, and responsible production practices.

IMARC Group: Unmatched Expertise, Comprehensive Services

- Data-Driven Market Research: Deepen your understanding of bioplastics market dynamics, consumer preferences, and technological advancements including PHA development, PLA innovations, and bio-based polymer solutions through comprehensive market research reports tailored to the Australian market landscape.

- Strategic Growth Forecasting: Predict emerging trends in sustainable packaging, biodegradable materials adoption, and government regulatory changes by analyzing regional market developments, consumer behavior shifts, and industrial applications across Australia's diverse economic sectors.

- Competitive Benchmarking: Analyze competitive forces in the Australian bioplastics market, review product development pipelines, and monitor technological breakthroughs in compostable packaging, agricultural applications, and advanced manufacturing processes that define market leadership.

- Policy and Infrastructure Advisory: Stay ahead of regulatory developments, government sustainability initiatives, and waste management policy changes affecting bioplastic manufacturing, distribution, and end-of-life management across Australian states and territories.

- Custom Reports and Consulting: Access tailored insights aligned with your organizational objectives whether introducing sustainable packaging solutions, investing in bioplastic manufacturing capabilities, or developing infrastructure for the circular economy in Australia's rapidly evolving market.

At IMARC Group, our mission is to empower industry leaders with the clarity and intelligence required to navigate Australia's dynamic bioplastics landscape. Join us in building a sustainable future because every innovation toward environmental stewardship matters.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)