Nutraceuticals Manufacturing Cost Analysis: The Wellness Cost Curve

What are Nutraceuticals?

Nutraceuticals are bioactive, health-enhancing products derived from food sources, botanical ingredients, or purified nutrients that provide physiological benefits beyond basic nutrition. They include dietary supplements, functional foods, fortified beverages, herbal extracts, probiotics, omega-fatty-acid formulations, vitamins, minerals, and specialized nutritional compounds. Nutraceuticals are designed to support wellness, prevent nutrient deficiencies, and promote specific health outcomes, including the improvement of immunity, digestive balance, cognitive function, metabolic health, or cardiovascular support. Manufactured under controlled quality systems, nutraceuticals merge scientific formulation with natural bioactives, and position themselves between conventional food products and therapeutic interventions within the greater health-and-wellness ecosystem.

Key Applications Across Industries:

Nutraceuticals serve a wide range of applications, including preventive, restorative, and performance enhancement for diverse consumer groups in different clinical settings. One of the most common uses of nutraceuticals is in the area of micronutrient deficiencies, where there may be targeted supplementation with vitamins, minerals, amino acids, or essential fatty acids. The products maintain basic physiological functions such as bone health, energy metabolism, immune resilience, and cellular repair. Probiotics and prebiotics play an important role in gut health modulation, supporting proper digestion and absorption of nutrients, while maintaining microbiome balance.

Nutraceuticals play a vital role in chronic-disease risk management for healthy cholesterol, glucose metabolism, weight management, and inflammation control. Curcumin, ashwagandha, ginseng, and resveratrol are some examples of botanical extracts that find applications in stress-related, cognitive performance-enhancing, antioxidant protection-related, and hormonal balance-ensuring formulas for healthy aging. Sports and active lifestyles depend increasingly on protein supplements, amino acid blends, hydration formulas, and nutraceuticals that support joints for endurance, recovery, and resilience.

Nutraceuticals are used in complementary and specialized segments like maternal health, pediatric supplementation, and senior nutrition, where tailored formulations support lifecycle-specific needs. Fortified cereals, probiotic drinks, plant-based protein products, and nutrient-enriched snacks-all fall within the scope of functional foods and beverages that expand nutraceutical applications into everyday dietary selections. Clinical practitioners may recommend nutraceutical interventions as complementary support alongside medical treatments, provided they meet regulatory standards and quality criteria. Their wide range of dosage forms-capsules, powders, gummies, beverages, bars, and ready-to-drink formats-facilitates wide consumer adoption and is easy to integrate into daily routines.

What the Expert Says: Market Overview & Growth Drivers

The global nutraceuticals market reached a value of USD 500.0 Billion in 2024. According to IMARC Group, the market is projected to reach USD 877.8 Billion by 2033, at a projected CAGR of 6.5% during 2025-2033. The global nutraceuticals market is driven by a combination of demographic, health, economic, and technological factors all pointing to sustained long-term growth. A key driver is increasing consumer awareness of preventive healthcare. As the incidences of lifestyle-related ailments such as obesity, diabetes, cardiovascular diseases, and metabolic disorders continue to increase, so does the need for accessible and non-pharmaceutical modes of maintaining good health and minimizing risks to health. Nutraceuticals fit this trend by offering science-based, natural, and personalized products.

Demographic trends significantly reinforce demand. The aging populations in North America, Europe, and parts of Asia create steady needs for products related to mobility, cognitive function, immunity, and the management of chronic conditions. Meanwhile, younger demographics also increasingly adopt nutraceuticals for fitness, beauty-from-within, stress management, and performance optimization, expanding the consumer base of this market.

Other powerful drivers are the rise of e-commerce and direct-to-consumer digital channels that raise awareness, allow for personalization of product choice, and speed up the adoption of new products. Social-media-driven health culture and influencer-led education further amplify consumer engagement. Regulatory modernization in many regions, with an emphasis on product quality, safety, and labeling transparency, has strengthened consumer trust and encouraged formal sector growth.

Scientific developments in nutrigenomics, microbiome research, bioavailability enhancement, plant-based actives, and functional-ingredient extraction have enhanced product efficacy and diversification, enabling the manufacturer to address very specific health outcomes. Besides that, growth into functional food and beverage formats will help bridge the gap between traditional dietary habits with modern nutritional supplementation, reinforcing cross-category expansion.

Other factors that spur demand include increasing disposable incomes in developing economies and the globalization of wellness culture. Together, these factors-preventive health behavior, demographic shift, technology-enabled access, regulatory support, and innovation-continue to push the nutraceuticals market onward globally.

Case Study on Cost Model of Nutraceuticals Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale nutraceuticals manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed nutraceuticals manufacturing plant in India. This plant is designed to manufacture 200 tons of nutraceuticals annually.

Manufacturing Process: Nutraceuticals are manufactured through a structured raw-material selection, formulation, processing, quality assurance, and packaging sequence designed to ensure the safety, efficacy, and consistency of the final product. Production begins with sourcing botanical extracts, vitamins, minerals, amino acids, probiotics, enzymes, or functional food ingredients that meet predefined purity, potency, and traceability criteria. The materials are subjected to identity testing, microbial screening, and contaminant analysis before release to formulation. During formulation, research and development teams determine the optimal ingredient ratios, delivery format, and bioavailability-enhancing technologies such as microencapsulation, chelation, or controlled-release systems. The approved blend is prepared through precise weighing and homogeneous mixing using high-shear blenders or fluidized mixing systems to ensure uniform distribution of active components. The manufacturing technique varies depending on the dosage form: capsule, tablet, powder, liquid, gummy, or functional food. Capsules are filled via automated encapsulation machines, while tablets undergo granulation, compression, and coating to enhance stability and swallowability. Powders are milled and then blended into a uniform mixture that is filled into containers or sachets. Liquids require processes of solubilization, emulsification, and pasteurization, followed by hot or cold filling. Among the nutraceuticals, probiotics and enzymes require specialized handling to maintain viability/activity, requiring controlled temperature conditions. During manufacturing, in-process quality control tests continuously monitor blend uniformity, tablet hardness, moisture content, microbial load, and potency of active ingredients. Finished products undergo stability testing to ensure shelf life and performance across a wide range of environmental conditions. Immediately following validation, nutraceuticals are packed in tamper-evident, moisture-resistant materials, correctly labeled, and ready for distribution in accordance with GMP guidelines.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

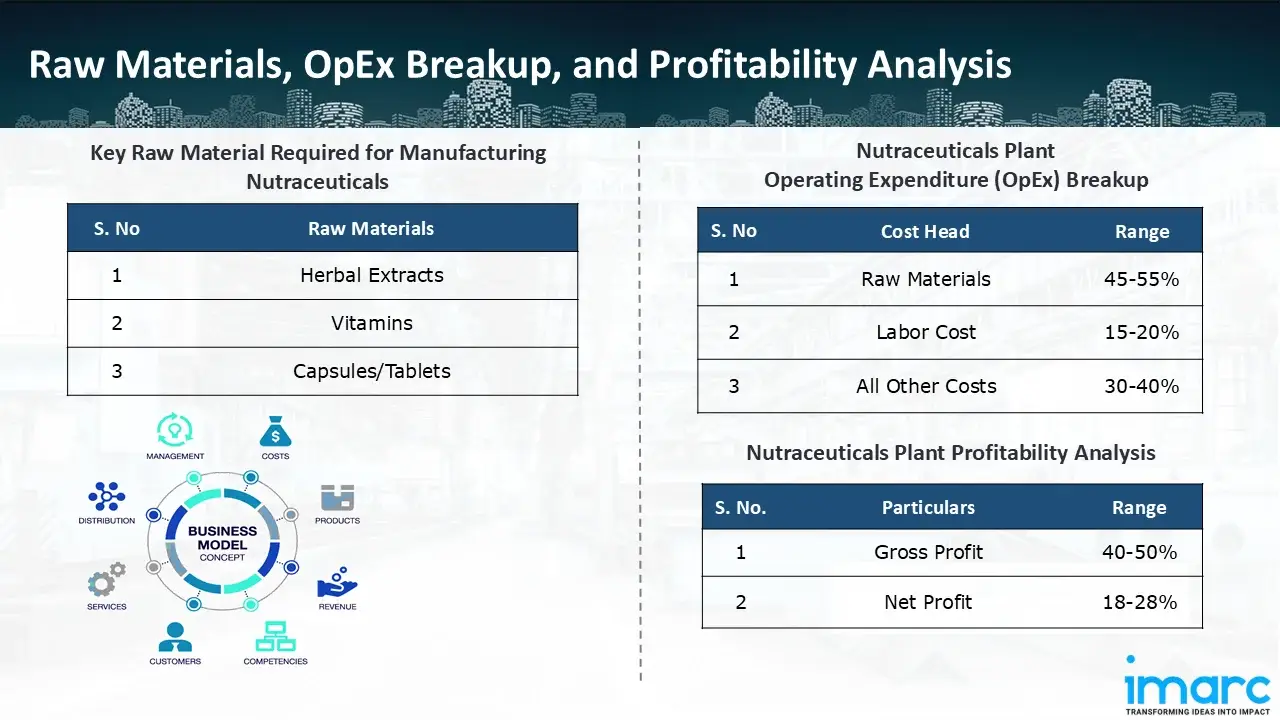

The basic raw materials required for nutraceuticals manufacturing include:

- Herbal Extracts

- Vitamins

- Capsules/Tablets

Machine Section or Lines Required:

- Extraction

- Mixing

- Granulation

- Tablet/Capsule Filling

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in nutraceuticals manufacturing plant ranges between 45-55%, labor cost ranges between 15% to 20%, and all other costs ranges between 30-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 40-50%, and net profit lie between the range of 18-28% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the nutraceuticals manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 200 tons of nutraceuticals annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, Otsuka Pharmaceutical Co., Ltd. will begin selling POCARI SWEAT in India. This product has a balance of ions, or electrolytes, which replace the fluids your body needs to sustain and promote improved health. This is a component of its global expansion of the nutraceutical industry.

- In April 2024, the Better Nutrition firm, Glanbia plc, stated that it has reached a deal with the owners of Flavour Producers LLC and the shareholders of Aroma Holding firm, LLC and affiliated entities to purchase the company for $300 million up front plus deferred consideration.

- In April 2024, Dr. Reddy's Laboratories Ltd. and Nestlé India Limited announced a final agreement to establish a joint venture to provide consumers in India and other specified territories with cutting-edge nutraceutical brands. The collaboration would combine the robust and well-established commercial strengths of Dr Reddy's in India with the well-known worldwide line of nutritional health solutions, vitamins, minerals, herbals, and supplements of Nestlé Health Science (NHSc).

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104