Fire Extinguisher Manufacturing Cost Model: Profitability in Fighting Fire

What is Fire Extinguisher?

A fire extinguisher is either a portable or fixed device that is designed to combat and suppress small fires by discharging a controlled substance, which cools the burning material, cuts off oxygen supply, or interrupts the chemical chain reaction sustaining combustion.

Key Applications Across Industries:

It is among the most important items that comprise fire protection systems, finding wide applications in residential, commercial, industrial, and transport environments. Fire extinguishers fall into five major categories that denote the class of fire they are supposed to deal with: Class A for ordinary combustibles, Class B for flammable liquids, Class C for electrical equipment, Class D for metal fires, and Class K/F for cooking oils and fats. The main types are water-based, foam, dry chemical powder, carbon dioxide (CO2), clean agent, and wet chemical extinguishers, which are suited to specific fire hazards. The basic structure of a fire extinguisher consists of a cylindrical pressure vessel made of steel or aluminum that contains the extinguishing agent and a propellant, or compressed gas/stored pressure. When the user activates it, usually done by pulling a pin and pressing a lever, it will spray the extinguishing agent through a nozzle to douse the fire. The advanced technologies developed in extinguishers include modern versions: automatic, smart, and eco-friendly, which use non-toxic and fluorine-free agents to comply with environmental regulations. Fire extinguishers play a critical role in first-response fire safety, minimizing property damage, and saving lives before the arrival of fire services. With increasing emphasis on workplace safety and building codes, these devices have become indispensable across industries and public infrastructure, serving as the first line of defense against fire emergencies worldwide.

What the Expert Says: Market Overview & Growth Drivers

The global fire extinguisher market reached a value of USD 5.7 Billion in 2024. According to IMARC Group, the market is projected to reach USD 8.7 Billion by 2033, at a projected CAGR of 4.9% during 2025-2033. Safety regulations, urbanization, industrial growth, and technological innovation in fire protection systems are some of the factors driving the global market for fire extinguishers. Among them, tough implementation of fire safety norms and building codes by various governments and regulatory authorities around the world is considered one of the main driving factors. Rapid urban development with a growing number of commercial complexes, residential high-rise buildings, and industrial units has increased the emphasis on installing fire protection systems, where fire extinguishers play a major role.

Besides this, increasing fire-related accidents in the manufacturing, energy, and transportation sectors have strengthened the demand for portable and fixed extinguishing systems that can suppress fire quickly. The demand has been increasing for extinguishers of different fire classes, such as foam and dry chemical powder types in oil and chemical storage areas, particularly from the growing industrial and warehousing sectors in developing economies. Further, the shift toward green and sustainable fire suppression technologies is also restructuring this market. Manufacturers are increasingly producing extinguishers based on non-fluorinated, biodegradable agents meant to replace traditional AFFF formulations due to environmental and health concerns. Moreover, the integration of IoT and smart monitoring systems into commercial fire safety infrastructure is pushing the demand for connected fire extinguishers, which notify maintenance personnel of the need for refilling or servicing. Broadened construction activities in Asia-Pacific, firmer fire codes in Europe, and modernization of safety infrastructure in the Middle East and North America drive consistent demand. All these factors point to the increasing recognition globally of fire extinguishers as vital, lifesaving equipment at the core of industrial safety, environmental sustainability, and protection of public health.

Case Study on Cost Model of Fire Extinguisher Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale fire extinguisher manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed fire extinguisher manufacturing plant in India. This plant is designed to manufacture 25,000 units of fire extinguisher annually.

Manufacturing Process: A fire extinguisher manufacturing process involves several stages of precise engineering, assembly, and testing to ensure safety, durability, and adherence to international fire safety standards. The design and material selection mark the beginning, where the engineers decide upon the type-water, foam, CO2, dry chemical, or clean agent-and the cylinder specifications that correspond to each type. The body of the extinguisher, usually made from high-grade carbon steel or aluminum alloy, is manufactured through deep drawing or extrusion processes, which transform the metal into a seamless cylindrical container able to hold high pressure. The cylinder is then heat-treated and shot-blasted to improve tensile strength by removing surface imperfections. Once the shell is prepared, it undergoes welding or crimping operations to attach the base and neck ring. Each welded joint is inspected through NDT techniques, which include hydrostatic pressure tests or X-ray inspections for airtightness and structural integrity. The cylinder is then internally cleaned and coated-either with anti-corrosion epoxy or a zinc-based layer-to prevent rust and chemical reactions with the extinguishing agent. The body is powder-coated or painted externally for durability and aesthetic appeal. This is followed by filling and assembly. Based on the extinguisher type, the suitable extinguishing medium (such as dry powder, CO2, and foam concentrate) and propellant (compressed nitrogen, CO2 cartridge, or stored pressure gas) are filled under appropriate conditions. Valve discharge hose, pressure gauge, and safety pin are assembled and tested for leak prevention and proper functioning. Each unit undergoes quality checks, labelling, and certification at the end to ensure safety standards such as ISI, CE, UL, or EN3 before packaging and distribution. This whole process ensures that every fire extinguisher performs reliably and effectively in emergency situations.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

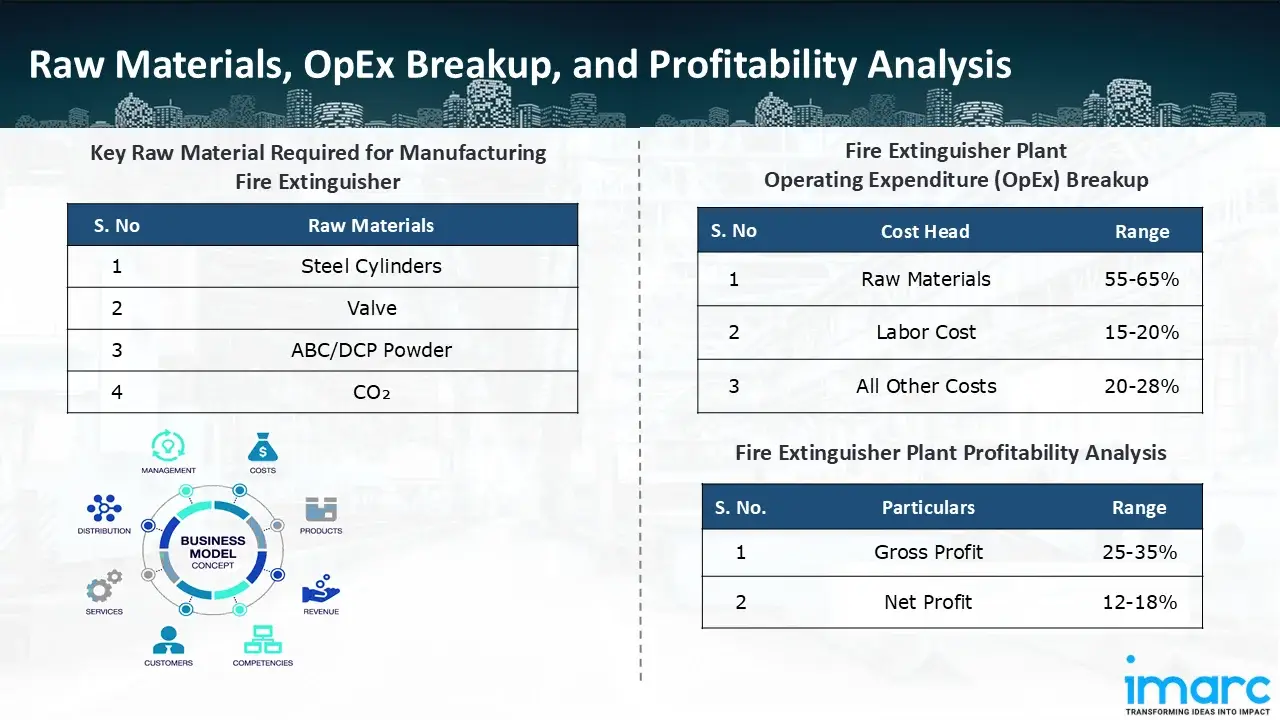

The basic raw materials required for fire extinguisher manufacturing include:

- Steel Cylinders

- Valve

- ABC/DCP Powder

- CO2

Machine Section or Lines Required:

- Cylinder Fabrication

- Valve Assy

- Filling

- Testing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in fire extinguisher manufacturing plant ranges between 55-65%, labor cost ranges between 15% to 20%, and all other costs ranges between 20-28% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-35%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the fire extinguisher manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 25,000 units of fire extinguisher annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2024, the Commercial and Residential Fire division of Carrier Global Corporation has been successfully acquired by an affiliate in a $3 billion deal, according to Lone Star Funds. The deal will result in the company functioning independently under the new name Kidde Global Solutions.

- In June 2024, FCL reaches a significant commercial milestone with the first sales of its exclusive FCL-X® lithium-ion battery fire-extinguishing agent to a worldwide EV OEM at its EV factory in the State of Georgia, USA. Other EV OEMs, more than 27,000 fire and rescue agencies in the United States, and other commercial and industrial players are the targets of current commercialisation initiatives.

- In April 2024, Johnson Controls announced that BSI, the business improvement and standards company, has certified the ANSUL R-102 Restaurant Fire Suppression System to EN 17446 standards (Kitemark 804125). The system's reputation as a dependable and trustworthy way to protect food service kitchens from the catastrophic effects of restaurant fires worldwide is further cemented by the new accreditation.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104