Onion Powder Manufacturing Cost Analysis: The Dehydration Ledger

What is Onion Powder?

Onion powder is a dehydrated and ground seasoning that results from the drying of fresh onions into a concentrated powdered form. The process of dehydration removes moisture from the product, while maintaining the flavor, aroma, and pungency characteristics of the onion, thereby making it a stable and ready-to-use ingredient with a longer shelf life. Onion powder can be prepared through various controlled drying, grinding, and screening processes from white, red, or yellow onion varieties. This powder product exhibits consistent particle size, strong flavor profile, and ease of incorporation, thus finding widespread applications in both culinary and industrial outlets as a uniform and value-added alternative to fresh onions.

Key Applications Across Industries:

Large-scale applications of onion powder in the food, culinary, and food-processing industries result from its high degree of flavor, convenience, and functional versatility. Onion powder is mainly used as a fundamental seasoning in household cookery, in soups, sauces and gravies, marinades, stews, and blends of dry rubs, providing consistent flavor without having to undertake tedious chopping, sautéing, or handling fresh onions. The food service operators prefer onion powder because it ensures labor efficiency, portion control, and reduction in waste, which are especially crucial in service sites characterized by large volumes, such as quick-service restaurants, catering kitchens, and institutional dining.

Onion powder is an important constituent in snack seasoning blends, instant noodles, ready-to-eat meals, frozen foods, dressings, and powdered soup mixes in industrial food manufacturing. Further, its dispersing ability, whether in a dry or wet formulation, would ensure consistency in taste for lot-to-lot standardization. It also helps with flavor layering in savory profiles, amplifying umami depth and acting as a natural flavor enhancer. Meat processors add onion powder to sausages, patties, meatballs, and plant-based protein formulations to create flavor and consistency in aromas.

Beyond direct flavoring, onion powder contributes to functions like moisture control in seasoning blends and extended shelf stability in packaged foods. Natural-product and clean-label brands incorporate onion powder into their formulations as a recognizable ingredient that is largely minimally processed and appealing to consumer desires for more transparent ingredient lists. With a long shelf life, microbiological stability, and various applications across cuisines such as Asian, Mediterranean, Latin American, Middle Eastern, and Western, the prevalence of onion powder has been reinforced.

What the Expert Says: Market Overview & Growth Drivers

The global onion powder market reached a volume of 73,100 Tons in 2024. According to IMARC Group, the market is projected to reach 98,700 Tons by 2033, at a projected CAGR of 3.4% during 2025-2033. Multiple, well-integrated driving forces help in the expansion of the onion powder market globally, from food industry expansion to supply-chain efficiency needs, consumer behavior, and technological developments in dehydration. A key driver is the surging demand for convenience foods, encompassing ready-to-eat meals, snacks, packaged seasonings, and instant foods. Dehydrated flavoring systems underpin such categories; onion powder represents a foundational ingredient due to its intense flavor and accessibility in a mix into automated manufacturing processes. Throughout urbanization, increasingly time-constrained consumers turn to prepared and semi-prepared foods, further boosting demand for unproblematic, user-friendly seasoning blends.

Another major driver is the need of the foodservice sector for consistency, cost efficiency, and scalability. Onion powder reduces labor associated with peeling and chopping onions, eliminates spoilage risks, and ensures standardized flavor across multiple outlets, critical for restaurant chains and industrial kitchens. For emerging markets, the rapid expansion of quick-service restaurants and packaged-food firms significantly raises bulk procurement of dehydrated onions.

The various technological advances, like low-temperature dehydration, vacuum drying, continuous belt drying, and microbial-control systems, in the drying sector have improved product quality, retained color, and preserved flavor. This has enhanced its global competitiveness and has opened up further opportunities for the application of onion powder. Resilience in the supply chain also strengthens market adoption because onion powder, having a long shelf life along with reduced transportation weight, is quite ideal for international trade and storage, thus supporting steady supplies even if fresh onion prices are volatile.

Cleaning-label preferences and shifts toward natural ingredients in many global regions further drive the usage, as manufacturers increasingly replace artificial flavor enhancers with identifiable, plant-based alternatives. Simultaneously, expanding export capabilities in major producing areas (especially India, China, and parts of the U.S.) continue to increase supply and reduce prices. These trends together underpin strong continued global growth for onion powder manufacturing. Manufacturing Process: The processing of onion powder is systematically undertaken through a series of steps involving cleaning, preparation, dehydration, milling, and quality control with the view of turning fresh onions into a stable, fine, flavorful powder that can be used in the food industry or cooking.

Case Study on Cost Model of Onion Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale onion powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed onion powder manufacturing plant in India. This plant is designed to manufacture 300 tons of onion powder annually.

Manufacturing Process: Manufacturing onion powder starts by sourcing mature, high-solids onions-they could be either white or red-onions that have been selected based on pungency, low moisture, and uniformity in size. Cleaning, mechanically peeling, and trimming are done to eliminate undesirable material and imperfect parts from the onions. The onions, after peeling, are cut into slices or diced into controlled sizes with the aim of assuring uniform dehydration. The prepared onion pieces are then conveyed to dehydration units, which could be hot-air dryers, continuous belt dryers, or low-temperature drying systems, all designed to preserve the flavor compounds while reducing the moisture content to less than 5 percent. Proper dehydration is important for the prevention of microbial growth and assurance of a very long period of storage. The dehydrated onion flakes or granules, once completely dry, are then allowed to cool before passing through grinding mills such as hammer mills or pin mills to reduce it to the desired particle size. Powder obtained is sifted through screeners for uniformity and particle oversize removal. Depending on the application, the powder may undergo sterilization, metal detection, and blending for flavor profile requirements. Throughout the process, the various quality controls monitor moisture content, color, volatile oil levels, microbial load, and particle uniformity. Finally, the finished onion powder is packed into moisture-tight bags, drums, or bulk containers to preserve freshness and to prevent caking. Controlled packaging and storage conditions ensure product stability during distribution to food processors, wholesalers, and retail markets.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

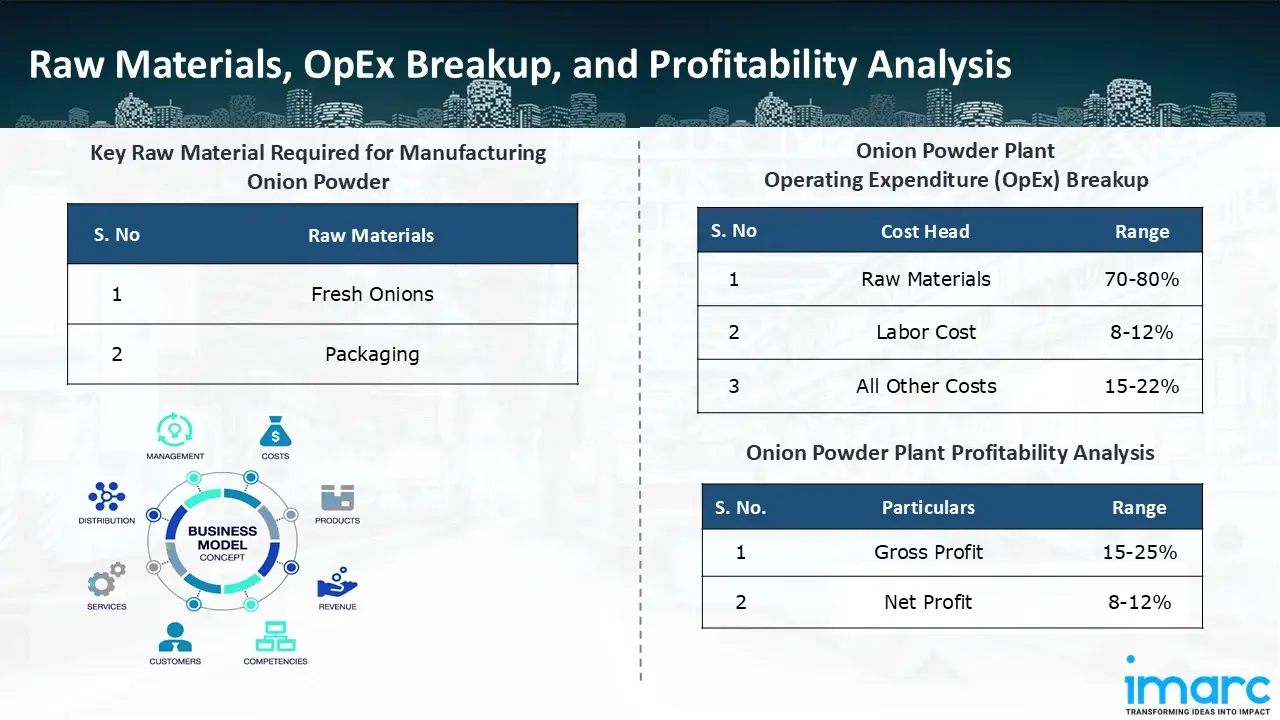

The basic raw materials required for onion powder manufacturing include:

- Fresh Onions

- Packaging

Machine Section or Lines Required:

- Slicing

- Drying

- Milling

- Sieving

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in onion powder manufacturing plant ranges between 70-80%, labor cost ranges between 8% to 12%, and all other costs ranges between 15-22% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-25%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the onion powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 300 tons of onion powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104