Graphite Manufacturing Cost Analysis: From Carbon to Capital

What is Graphite?

Graphite is a crystalline form of pure carbon, where atoms are organized in layered hexagonal structures, reflecting exceptional lubricity, electrical conductivity, heat resistance, and a high degree of chemical stability. It comes in many forms: flake, amorphous, vein, and synthetic graphite-derived from petroleum coke or coal tar pitch. Because of this layered structure, the sheets slip easily, which gives graphite its characteristic softness and lubricity, while strong covalent bonding within the layers makes it thermally stable and conductive. The unique characteristics make graphite indispensable in uses such as steelmaking, refractories, batteries, electronics, and in high-performance industrial components.

Key Applications Across Industries:

Graphite finds a wide range of applications across many industries due to its unique combination of electrical, thermal, chemical, and mechanical properties. In metallurgy, graphite is used in refractories, ladles, crucibles, and molds because it can withstand extremely high temperatures without deformation. The steel industry depends on graphite electrodes in electric arc furnaces, thus playing a crucial role in the recycling of steel and production of alloys. In energy storage, graphite is the current main anode material in lithium-ion batteries, which power electric vehicles, consumer electronics, and renewable energy storage systems. Its stability, conductivity, and ability to host lithium ions make it irreplaceable in modern battery chemistry.

In lubricants, it finds application in dry lubricants, greases, and at high temperatures where ordinary oils cannot work. In the field of electronics and electrical engineering, graphite is used in brushes for electric motors, conductive pads, grounding systems, and thermal management materials owing to its excellent conductivity. The mechanical uses involve seals, gaskets, bearings, and components of an assembly used in extreme industrial environments. Graphite offers resistance to corrosion for applications related to the chemical industry, including heat exchangers, reactors, and processing equipment. Other uses are in pencils, paints, coatings, brake linings, carbon brushes, fuel cells, and new composite materials such as graphene-enhanced materials. The range of applications of graphite keeps expanding with advances in clean energy, lightweight materials, and high-performance technologies.

What the Expert Says: Market Overview & Growth Drivers

The global graphite market reached a value of USD 7.81 Billion in 2024. According to IMARC Group, the market is projected to reach USD 14.11 Billion by 2033, at a projected CAGR of 6.9% during 2025-2033. The global graphite market is shaped by powerful structural drivers linked to electrification, clean energy, industrialization, and advanced material development. Perhaps the most influential driver is the rapid and explosive growth of the electric vehicle industry through battery electric vehicles, which depend on lithium-ion batteries. Both natural and synthetic graphite comprise the overwhelming bulk of the anode material in such batteries, making graphite indispensable in these electric vehicle production and energy storage systems. As governments continue to push for decarbonization and automakers scale up battery gigafactories around the world, demand for battery-grade graphite has continued to surge.

Meanwhile, the renewable energy sector is growing, further boosting demand for stationary battery storage solutions. Graphite's role in grid-scale batteries, solar-energy storage, and backup power systems reinforces its strategic importance. The metallurgical industry continues to be another strong demand center, especially as electric arc furnace steelmaking grows worldwide. Graphite electrodes are indispensable in EAF operations, while increasing global rates of steel recycling have acted to further bolster demand.

Acceleration in technological development is also contributing to market growth. Development in graphite-based composites, graphene technologies, advanced lubricants, and thermal applications has opened up additional high-value markets. Increasingly, interest in the diversification of supply chains, spurred by geopolitical concerns and the concentration of processing operations in specific regions, drives investments into new mining projects, synthetic graphite facilities, and downstream processing plants across North America, Europe, Africa, and Australia. Further, the rise of industrialization in developing countries is driving up demand for graphite-based refractories, lubricants, and mechanical parts. As industries move toward high-temperature, energy-efficient, and corrosion-resistant materials, the relevance of graphite keeps on increasing. These trends altogether place graphite as a crucial material in the transition to sustainable energy, advanced manufacturing, and technological innovation.

Case Study on Cost Model of Graphite Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale graphite manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed graphite manufacturing plant in India. This plant is designed to manufacture 3,000 tons of graphite annually.

Manufacturing Process: Graphite, whether produced from natural or synthetic sources, requires different processes that essentially transform carbon-rich materials into highly purified, structurally stable graphite that could be used in various industries and technologies. The processing of natural graphite begins with mining, which can be open pit or underground, depending on the location of the graphite deposit. This is followed by a process of crushing and grinding the ore. The material then undergoes flotation, where graphite flakes are separated from gangue minerals through the use of water, chemical reagents, and air bubbles. Following flotation, the concentrate is then screened, dewatered, and dried, after which it undergoes purification processes such as chemical leaching or thermal treatment to raise the carbon content to the range of 90-99.9%. Depending on applications, such as anodes for batteries, refractories, or lubricants, purified graphite may undergo further shaping by milling, spheroidization, micronization, or coating. For synthetic graphite, the process starts with high-purity petroleum coke or needle coke, mixed together with coal tar pitch as a binder. The mixture is then extruded or molded into shapes in demand, such as electrodes or blocks, and baked at temperatures around 800-1,200°C to carbonize the binder. After baking, the material undergoes additional impregnation with pitch to fill pores, followed by a second baking stage to improve strength further. The most critical step is graphitization, whereby the carbonized material is heated to very high temperatures (2,500 to 3,000°C) in an electric furnace. This rearranges the carbon atoms into graphite's characteristic layered crystalline structure, dramatically improving conductivity, thermal stability, and mechanical properties. After graphitization, the product is machined, purified, and finished based on specifications such as size, density, and grain structure. Whether natural or synthetic, the manufacturing process emphasizes purity, structural integrity, and consistency, allowing graphite to be used in demanding applications like batteries, refractories, lubricants, electrodes, and advanced composites.

Get a Tailored Feasibility Report for Your Project Request Sample

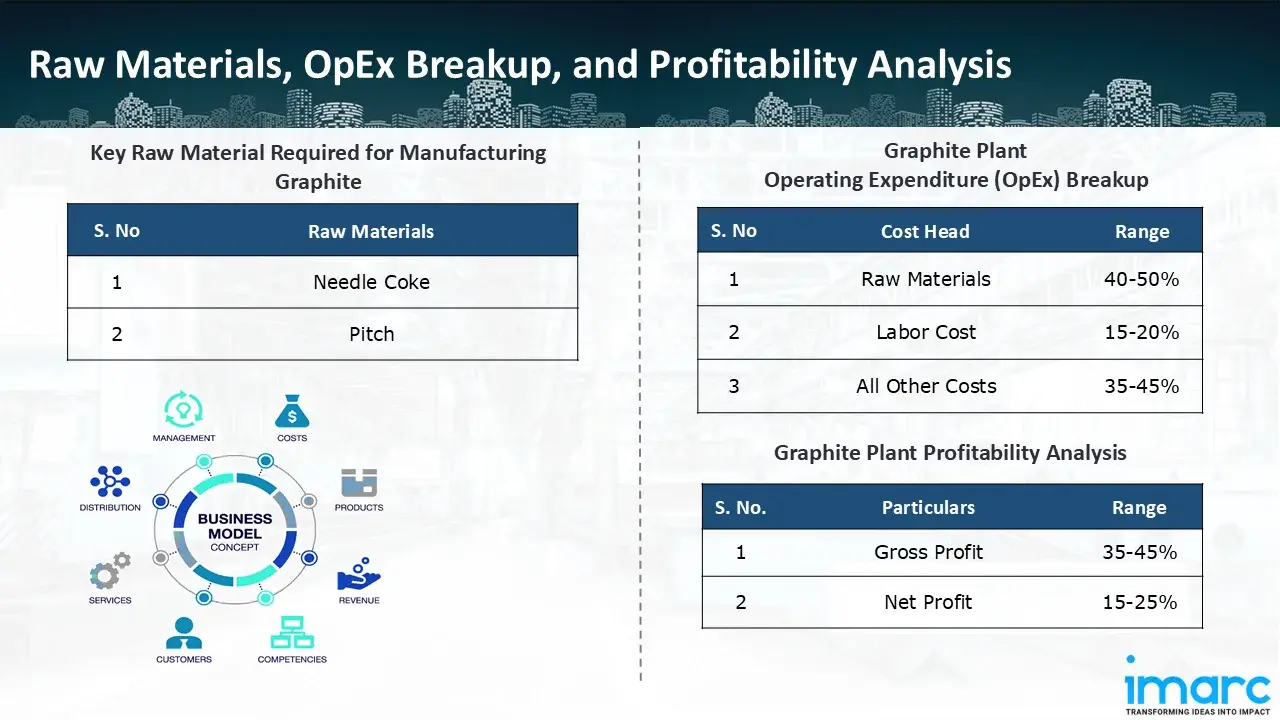

Raw Material Required:

The basic raw materials required for graphite manufacturing include:

- Needle Coke

- Pitch

Machine Section or Lines Required:

- Calcination

- Mixing

- Baking

- Graphitization

- Machining

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in graphite manufacturing plant ranges between 40-50%, labor cost ranges between 15% to 20%, and all other costs ranges between 35-45% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 35-45%, and net profit lie between the range of 15-25% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the graphite manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 3,000 tons of graphite annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, Imerys Graphite and Carbon Switzerland Ltd. (IGC), a wholly-owned subsidiary of Imerys SA and the world leader in conductive carbon black, announced a strategic alliance with Jiangsu Cnano Technology Co., Ltd., the world leader in carbon nanotubes. In order to improve the performance of next-generation electric vehicle (EV) batteries, this partnership brings together two industry leaders in their respective fields to create novel conductive additive solutions that combine carbon nanotubes with carbon black.

- In July 2025, Australian mineral producer Syrah Resources has resumed large-scale graphite shipments from its 350,000 t/yr Balama mine in Mozambique ahead of schedule after months of delays due to protests.

- In January 2025, General Motors has chosen Vianode, a cutting-edge battery materials business, as a critical provider of high-performance anode graphite solutions. The deal involves the expansion of synthetic anode graphite supplies and large-scale manufacturing capacity through 2033.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104