HDPE Pipe Manufacturing Cost Analysis: Industrial Cost Intelligence

What is HDPE Pipe?

HDPE pipes are thermoplastic piping systems made from high-strength polyethylene resin, which features excellent flexibility, high impact resistance, and strong chemical and corrosion resistance. HDPE pipes are produced by extruding molten polyethylene into a variety of diameters and pressure ratings. Their seamless structure, along with their low friction and resistance to internal pressure and external load, makes them ideal for the transport of fluids. HDPE pipes boast superior endurance, long service life, and leak-free performance, since it is possible to join them through heat fusion, thus creating monolithic, continuous pipelines that are suitable for buried, aboveground, or underwater installations.

Key Applications Across Industries:

HDPE pipes are applied across water supply, wastewater management, gas distribution, industrial processing, agriculture, and infrastructure development, marking them among the most versatile piping materials in the world. In the water supply sector, HDPE pipes are widely used for potable water distribution on account of resisting corrosion, scaling, and bacterial growth, thus ensuring safe and clean water transportation. Municipal systems also make use of HDPE pipelines for sewer networks, stormwater drainage, and wastewater treatment because the material resists harsh chemicals and abrasive slurries.

HDPE pipes are preferred in gas distribution for low- and medium-pressure natural gas networks due to the strength of the pipe and leak-proof fusion joints. In agriculture, such pipes find applications in irrigation systems, drip lines, sprinkler systems, and borewell because of their flexibility and UV resistance. HDPE pipes deployed in industries include those used for chemical transportation, slurry lines, mining operations, and industrial effluent transportation, where the need is for very strong and non-reactive piping due to corrosive material handling.

HDPE pipes are also used for district cooling, cable ducting, and telecom conduits due to their thermal stability and ease of installation. Their resistance to trenchless technologies, including horizontal directional drilling and pipe bursting, enables use in urban environments with minimal surface disruption. Overall, HDPE pipes are an economical, reliable, and long-lasting solution in new installations and rehabilitation projects alike.

What the Expert Says: Market Overview & Growth Drivers

The global HDPE pipe market reached a value of USD 22.0 Billion in 2025. According to IMARC Group, the market is projected to reach USD 30.9 Billion by 2034, at a projected CAGR of 3.88% during 2026-2034. The global HDPE pipe market is driven by a mix of infrastructure expansion, water management needs, urbanization, and increasing adoption of durable, corrosion-free piping systems. Among the key drivers is the concerted effort across the world on enhancing water supply and sanitation infrastructure, particularly in developing economies where aging pipelines and leakage losses demand refitting with more reliable systems. HDPE pipes are better suited for both new networks and rehabilitation projects due to their long service life, flexibility, and leak-proof joining technology.

Other significant factors driving growth are the rising focus on irrigation modernization and agricultural efficiency. With increasing numbers of regions facing water shortages, governments and farmers are increasingly investing in HDPE-based drip and sprinkler systems to raise crop yields and enhance water-use efficiency. In parallel, HDPE pipes continue to be increasingly used for transporting chemicals, gases, slurries, and industrial effluents in the oil & gas and industrial sectors owing to their chemical inertness and mechanical strength.

These technological advances in extrusion processes, resin formulations, and trenchless installation methods have further accelerated their adoption. The modern HDPE pipe is much lighter yet stronger, and it comes in larger diameters than ever before, making them ideal for high-capacity water and sewer projects. The compatible trenchless technologies minimize installation time and urban disruption, offering cost advantages in municipal engineering works.

It also finds thriving demand in various urbanization and smart city development projects for telecom ducts, cable conduits, and district cooling pipelines, wherein HDPE provides durability and ease of handling. Besides this, increasing environmental regulations and sustainability commitments are driving industries to low-environmental-impact materials, recyclability, and reduced leakage rates. These factors combined ensure a strong, continued growth for HDPE pipes across applications in municipalities, industries, and agriculture worldwide.

Case Study on Cost Model of HDPE Pipe Manufacturing Plant

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale HDPE pipe manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed HDPE pipe manufacturing plant in India. This plant is designed to manufacture 6,000 tons of HDPE pipe annually.

Manufacturing Process: HDPE pipe manufacturing is a highly controlled process that involves the sequential operation of polymer preparation, melting, extrusion, cooling, sizing, and quality verification to create robust, high-strength piping systems. The manufacturing process starts with selecting HDPE resin, normally in pellet form, which may contain additives such as UV stabilizers, antioxidants, pigments, and processing aids to improve performance. The resin pellets are fed into a hopper and transported into a single-screw or twin-screw extruder, where they are gradually heated from 180°C to 220°C. Inside the extruder, rotating screws melt, homogenize, and pressurize the polymer. The molten HDPE is pushed through a circular die head to form a continuous cylindrical tube. As the pipe exits the die, it enters a vacuum calibration tank where vacuum pressure and sizing sleeves ensure uniform diameter, wall thickness, and roundness. The pipe then moves to cooling tanks immediately after shaping, either by water spray or immersion, which serves to solidify and stabilize the structure of the pipe. The cooling stage is very important because correct temperature control will avoid possible deformation and internal stresses. Once cooled, the pipe passes through haul-off units that sustain consistent production speed and tension. Following this, it is cut into standard lengths using automatic cutting systems or wound into coils in the case of smaller diameters. Along the length of the production line, sensors and control systems continuously monitor wall thickness, ovality, melt flow, surface finish, and tensile strength, ensuring that the product meets international standards such as ISO, ASTM, or BIS. Finally, the finished pipes are pressure-tested, visually inspected, and quality-certified before packaging and dispatch. This accurate, continuous extrusion process gives HDPE pipes exceptional durability, flexibility, and leak-free performance for water, gas, industrial, and agricultural applications.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

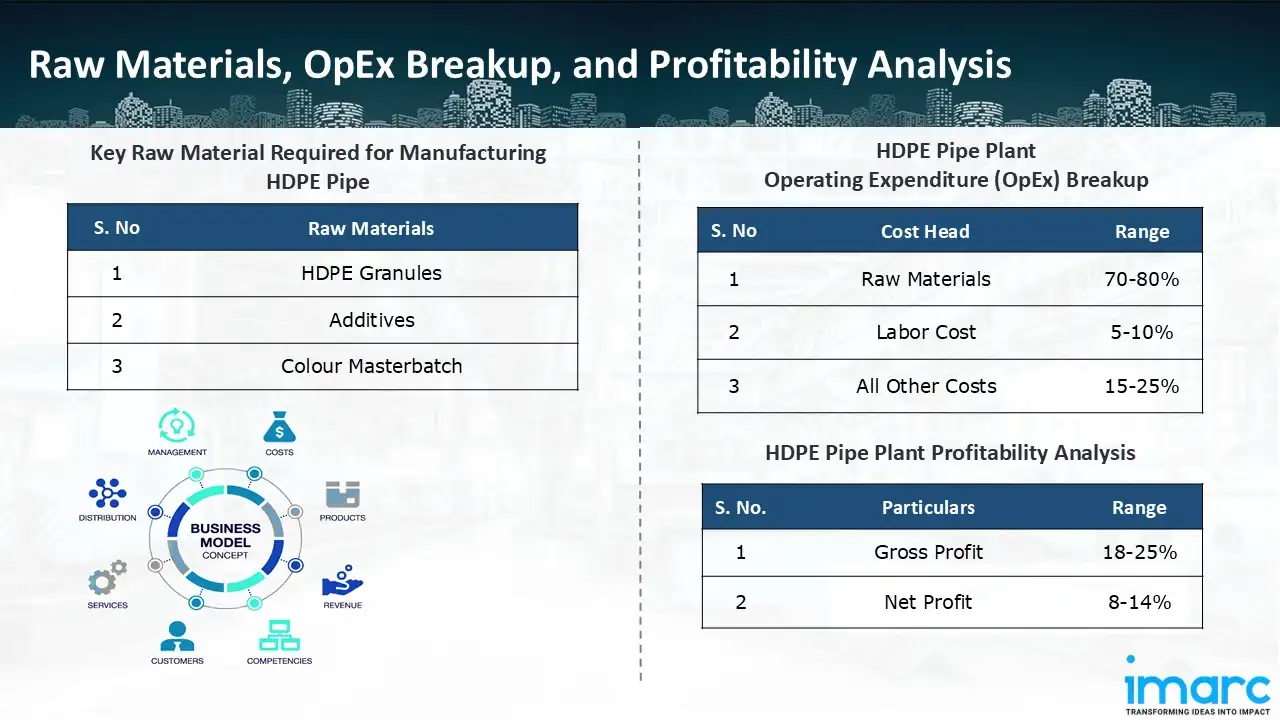

The basic raw materials required for HDPE pipe manufacturing include:

- HDPE Granules

- Additives

- Colour Masterbatch

Machine Section or Lines Required:

- Extruder

- Vacuum Tank

- Haul-off

- Printer

- Coiling

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in HDPE pipe manufacturing plant ranges between 70-80%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 18-25%, and net profit lie between the range of 8-14% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the HDPE pipe manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 6,000 tons of HDPE pipe annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In November 2025, Time Technoplast Ltd. has announced that it has received an order for about Rs. 190 crores from EPC (Engineering, Procurement, and Construction) Contractor to supply HDPE pipe products for power duct application projects carried out by Andhra Pradesh Capital Region Development Authority and Amaravathi Development Corporation Limited.

- In April 2025, IPEX, a leader in the development of plastic pipes and fittings, announced the grand opening of the IPEX Centre for Advanced Research, a $30 million investment in a cutting-edge facility intended to boost product innovation and strengthen the company's North American manufacturing operations.

- In March 2025, the building & infrastructure division of Orbia Advance Corporation S.A.B. de CV, a world leader in pipes and fittings, and Supreme Industries Ltd., a plastic pipe maker in India, announced their intention to enter into a long-term collaboration arrangement.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104