Lubricating Oil Production Cost Model: Fluid Fetching Profits

What is Lubricating Oil?

Lubricating oil is a specially formulated liquid substance that reduces friction, wear, and generation of heat between moving mechanical surfaces. It is usually made from refined mineral base oils, synthetic oils, or a mixture of both, supplemented with performance-improving additives such as anti-wear agents, detergents, dispersants, antioxidants, corrosion inhibitors, and viscosity improvers. The lubricating oil forms a film that separates the metal surfaces, thereby improving equipment efficiency by preventing deterioration of components and helping to cool down. It becomes indispensable in engines, machinery, industrial systems, and mechanical processes where accurate lubrication, cooling, and cleanliness are required for performance sustainability.

Key Applications Across Industries:

Lubricating oil finds essential applications in automotive, industrial, marine, aviation, production, agricultural, and power-generation operations. Engine oils used in cars, trucks, buses, and motorcycles lubricate moving components like pistons and bearings; they help cool, clean sludge, prevent oxidation, and maintain fuel efficiency. Transmission fluids and gear oils are other groups falling under the category of lubricants, which serve to support smooth gear shifts and torque transmission.

Industrial applications also include compressor oils, turbine oils, hydraulic oils, machine tool oils, metalworking fluids, and conveyor lubricants for maintaining stability of operation, reducing failure of components, and increasing service intervals. Hydraulic oils provide efficiency in power transmission equipment, while turbine oils contribute to the effectiveness of steam and gas turbines.

For extreme conditions of temperature and pressure, high-performance lubricants offer thermal stability and oxidation resistance in marine and aviation sectors. Lubrication is also needed for agricultural machinery, construction equipment, mining vehicles, and generators that work in rough and dusty conditions.

Specialty lubricants find their applications in food processing, pharmaceuticals, electronics, and renewable energy systems, such as wind turbines, where high reliability and contamination control are demanded. On the whole, lubricating oils are indispensable in ensuring efficiency, durability, and operational safety across diverse mechanical systems.

What the Expert Says: Market Overview & Growth Drivers

The global lubricants market reached a value of USD 141.70 Billion in 2024. According to IMARC Group, the market is projected to reach USD 203.50 Billion by 2033, at a projected CAGR of 3.9% during 2025-2033. The global lubricating oil market is driven by several technological, industrial, and economic factors that, in one way or another, increase demand across end-use sectors. Amongst the major drivers is the continued fleet expansion of automotive and industrial machinery, especially in emerging markets where production, transportation, and development of infrastructure are increasing rapidly. As vehicles are becoming more advanced, high-performance, low-viscosity, fuel-efficient lubricants, especially those needed in modern engines designed for the latest and strict emission regulations are consequently required.

Another powerful driver is industrial automation and mechanization growth, since sophisticated lubrication systems are required to provide for continuous, failure-free operation of production lines, robotics, turbines, and compressors. Further, expansion in mining, construction, power generation, and oil & gas maintains strong demand for durable lubricants that can resist extreme conditions.

Other factors that drive the market forward are technological advances in synthetic and semi-synthetic lubricants, which, compared to conventional mineral oils, offer superior performance, extended drain intervals, better oxidation stability, and greater environmental compatibility. Most industries are shifting toward synthetic oils to save on maintenance costs and enhance efficiency.

The rise of renewable energy, particularly wind energy, is driving demand for gear oils and greases that go into turbine gearboxes, bearings, and hydraulic systems. Correspondingly, marine regulations promoting low-sulfur operation spur use of specialized marine lubricants.

Besides this, economic growth, urbanization, expansion of e-commerce logistics, and consumer mobility also lead to rising consumption of lubricants worldwide. While electric vehicles will lower the demand for engine oil in the future, they increase demand for thermal management fluids, special greases, and gear lubricants, thereby shaping the future of lubricants. In totality, the global lubricating oil industry is supported by sustained industrial growth, evolving technology requirements, and the continuous need for efficiency and reliability in mechanical operations.

Case Study on Cost Model of Lubricating Oil Production Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale lubricating oil production plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed lubricating oil production plant in India. This plant is designed to manufacture 3 million litre of lubricating oil annually.

Production Process: The production of lubricating oil generally goes through three stages: crude oil refining, the addition of performance-enhancing additives via blending, and quality control measures. In the first stage, crude is separated into various fractions by heating it in a fractionating column. The heavier fractions that may be appropriate for base oil are sent on for further processing that involves removing the aromatic compounds present, by a process called solvent extraction, which interferes with its stability. Dewaxing may be either catalytic or solvent-based to remove wax content to improve the oil's performance at low temperature. Hydrocracking and hydro-isomerization advanced refining processes transform lubricant base oils into high-purity Group II, III, and IV stocks with superior oxidation stability and improved viscosity index. First, the base oil is made ready and then transferred to blending vessels, where a precise mixture of additives is added. These additives do various tasks: detergents reduce deposits, dispersants prevent the formation of sludge, antioxidants slow down degradation, anti-wear agents protect the metal surface, viscosity modifiers ensure stable flow across temperatures, and corrosion inhibitors protect components of an engine. Depending on the type-engine oil, hydraulic oil, gear oil, compressor oil, or turbine oil-the additive package is adjusted to performance requirements. Then, the mixture is homogenized, ensuring that additives are properly dispersed in the base oil. The blended lubricating oil is subjected to several quality tests, such as viscosity measurement, flash point determination, pour point analysis, oxidation testing, and conformance with the given standards like API, ACEA, or ISO. In the final stage of product validation, the finished oil is filtered, filled into containers, labeled, and packaged for distribution. This entire process ensures that lubricating oil meets the stringent performance, durability, and efficiency requirements demanded by modern machinery and engines.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

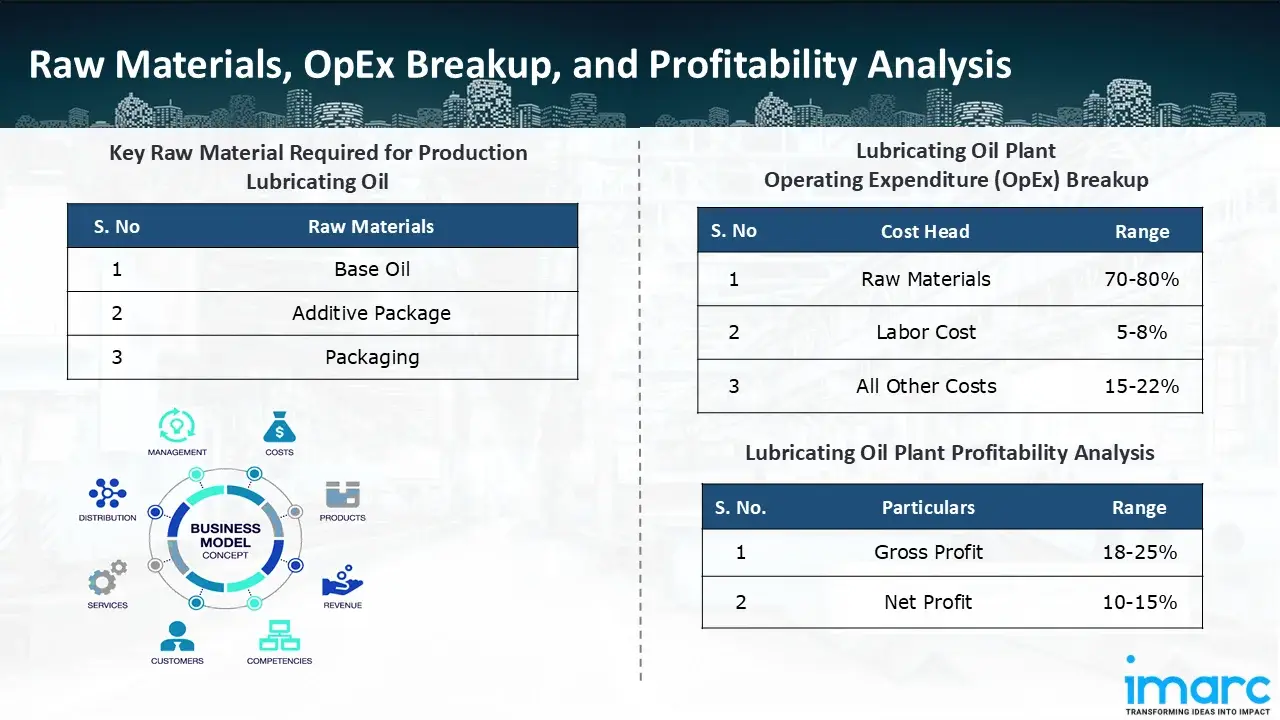

The basic raw materials required for lubricating oil production include:

- Base Oil

- Additive Package

- Packaging

Machine Section or Lines Required:

- Blending Tanks

- Filling Line

- Lab (QC)

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a production plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a production plant effectively. Opex in a production plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a production plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in lubricating oil production plant ranges between 70-80%, labor cost ranges between 5% to 8%, and all other costs ranges between 15-22% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 18-25%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the lubricating oil production plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, production, capital expenditure, and operational expenses. By addressing the specific requirements of production 3 million litre of lubricating oil annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale production ventures.

Latest News and Developments:

- In December 2025, Glockner Oil Company, a distributor of fuel and lubricants with locations in Piketon and Columbus, Ohio, was acquired by Cadence Petroleum Group as part of its ongoing growth.

- In November 2025, DuPont starts construction on a cutting-edge MOLYKOTE® Speciality Lubricants facility in China in order to promote regional growth and innovation.

- In March 2024, Shell Indonesia declared its intention to construct the country's first grease production plant (GMP). The new facility will support Shell's Marunda Lubricants Oil Blending Plant (LOBP), which is currently located in Bekasi, Indonesia.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the production facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish production facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104