Mineral Wool Ceiling Tiles Manufacturing Cost Analysis: Ceiling Solutions Cost Matrix

What is Mineral Wool Ceiling Tiles?

Mineral wool ceiling tiles consist of acoustic and thermal insulation panels fabricated from inorganic fibers, which originate mainly from molten basalt, slag, or other mineral-based raw materials. The fibers are spun and bonded together with resins, then compressed into rigid tiles that perform well in terms of sound absorption, fire resistance, and moisture tolerance. They are usually available in standard sizes for application in suspended ceiling systems in commercial, industrial, and institutional buildings. With their inherent non-combustibility and dimensional stability, these tiles are widely accepted because they help to improve indoor environmental quality and support building safety standards while boosting interior space performance.

Key Applications Across Industries:

Mineral wool ceiling tiles are used in infrastructure, commercial real estate, and industry for a variety of applications due to their acoustic, fire-resistant, and thermal-control properties. Their main application is in commercial office spaces where noise reduction and speech privacy are necessary for productivity. Mineral wool tiles effectively absorb airborne sound, making them suitable for open-plan offices, meeting rooms, call centers, and co-working environments. In educational institutions, such as schools, universities, and training centers, these ceiling systems help manage reverberation levels, helping to improve speech intelligibility and reduce ambient noise, which is critical for learning outcomes.

The healthcare facilities are another important application area, as mineral wool ceiling tiles support the stringent requirements of fire safety, resist microbial growth, and maintain the structural stability under conditions of fluctuating humidity. They find application in patient rooms, treatment areas, diagnosis zones, administrative spaces, and laboratories. Lastly, in hospitality environments such as hotels, restaurants, and conference venues, the tiles enhance guest comfort by improving acoustics and concealing mechanical systems behind aesthetically pleasing ceiling surfaces.

Industrial facilities and manufacturing plants also use mineral wool ceiling systems where thermal insulation and fire protection are required around process areas, control rooms, and storage spaces. The large retail chains, airports, metro stations, and public buildings install mineral wool ceiling tiles to balance acoustic comfort with strength and ease of maintenance. Because of their versatility, architects and facility managers will be able to combine the performance benefits with design flexibility in various building types.

What the Expert Says: Market Overview & Growth Drivers

The global mineral wool ceiling tiles market reached a value of USD 11.5 Billion in 2024. According to IMARC Group, the market is projected to reach USD 16.3 Billion by 2033, at a projected CAGR of 3.77% during 2025-2033. The global market for mineral wool ceiling tiles is primarily driven by a combination of regulatory, economic, technological, and construction-related factors that collectively elevate demand for high-performance interior building materials. A key driver is increasingly stringent fire-safety and building-code requirements implemented across regions such as North America, Europe, and parts of Asia. Because of its intrinsic non-combustibility, mineral wool is well-placed as a preferred material for ceilings in commercial buildings, healthcare institutions, transit hubs, and high-occupancy public spaces where compliance with life-safety standards is mandatory. Running in parallel, the global push toward sustainability and green building certification-through frameworks such as LEED and BREEAM, and through local energy-efficiency standards-promotes the use of materials with high recycled content and strong thermal performance, both of which favor mineral wool ceiling systems.

Other key drivers include rapid urbanization and infrastructure development across emerging economies. Countries experiencing growth in commercial real estate, institutional buildings, and industrial facilities are increasingly using suspended ceiling systems to enhance functionality and climate control in contemporary buildings. The better acoustic absorption characteristic of mineral wool also finds demand in the growing emphasis on occupant wellness, productivity, and acoustic comfort-particularly relevant in open offices, educational centers, and healthcare environments.

The current technological progress in manufacturing also means improved fiberization techniques, surface finishes, and integration of moisture-resistant properties, further enhancing product performance and aesthetics and widening acceptance among architects and interior designers. Besides that, renovation and retrofitting activity in mature economies also significantly contributes to demand, as older buildings replace obsolete ceiling systems with the latest standards and soundproofing, fire-safety, and energy-efficiency improvements. Finally, the continuous rise in industrial activities across the world and the increasing demand for a safe and controlled environment indoors in factories, data centers, and logistic facilities support continued consumption of mineral wool ceiling tiles. All these collectively create a strong long-term growth outlook for the global market.

Case Study on Cost Model of Mineral Wool Ceiling Tiles Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale mineral wool ceiling tiles manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed mineral wool ceiling tiles manufacturing plant in India. This plant is designed to manufacture 1 million square ft. of mineral wool ceiling tiles annually.

Manufacturing Process: The manufacturing process for mineral wool ceiling tiles involves a series of controlled thermal, mechanical, and finishing operations that produce dimensionally stable, acoustically efficient, and fire-resistant panels. Production begins with the melting of mineral-based raw materials-mineral types commonly include basalt, slag, and other naturally occurring stones-in a high-temperature furnace above 1,400°C. The molten mixture is then fiberized using spinning wheels or high-pressure air jets to create fine, interlocking mineral wool fibers. These fibers are then collected and mixed with binders, fillers, water-repellent additives, and sometimes recycled content, to enhance the structural integrity and performance of the material. In a forming drum or with a continuous belt system, the mixture is formed into a wet felt mat where precise control is provided over fiber distribution, density, and thickness. The wet mat is cured in a drying oven, during which the binders polymerize, and the panel acquires rigidity. Once cured, the material is cut to standardized tile dimensions and is further processed through sanding, edge profiling, and surface finishing. Surface treatments aimed at improving aesthetics, light reflectance, and durability may be performed, including painting, acoustic coatings, or laminated facings applied to the tiles. Tiles also undergo testing for fire resistance, humidity performance, acoustic absorption, and dimensional tolerances to ensure that industry performance standards have been met. Finally, finished tiles are packaged to protect against moisture and mechanical damage during transportation and installation. All along this process, manufacturers incorporate energy-efficient practices, dust-collection systems, and recycling loops to minimize waste and ensure uniformity in product quality. This multi-stage production system allows mineral wool ceiling tiles to be produced in high volume and with uniformity of quality for applications in commerce and institutions.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

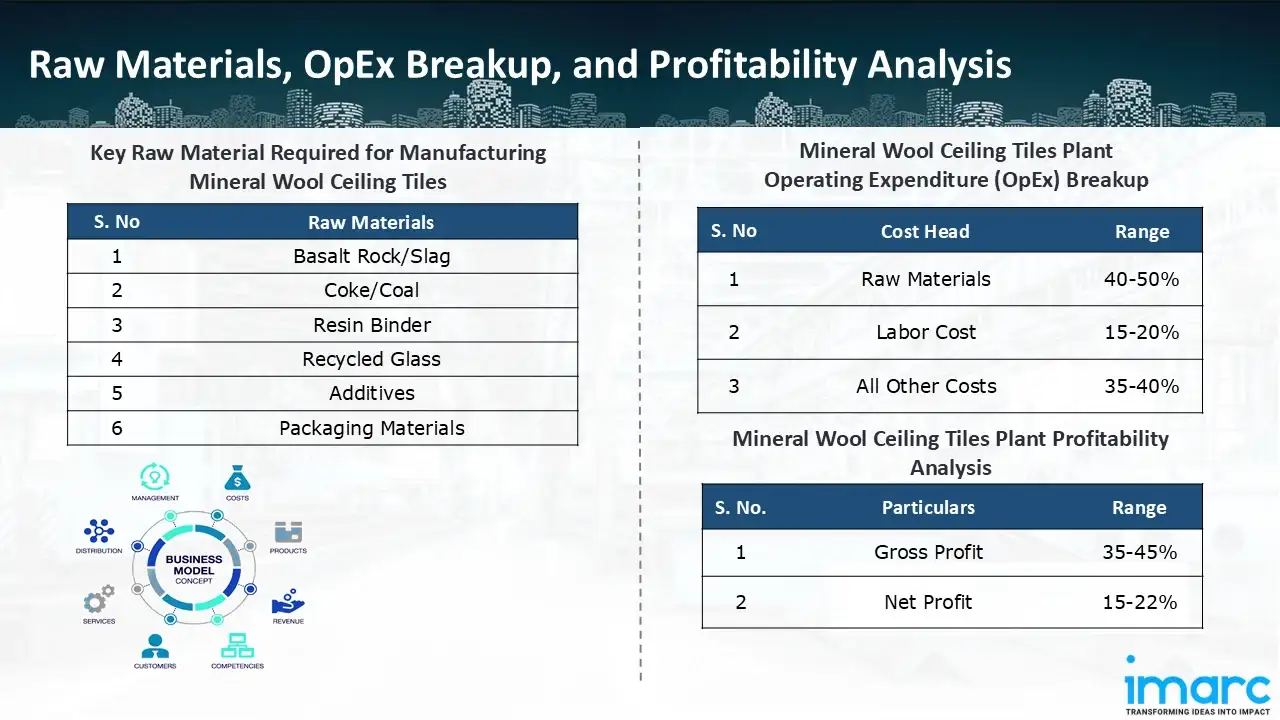

The basic raw materials required for mineral wool ceiling tiles manufacturing include:

- Basalt Rock/Slag

- Coke/Coal

- Resin Binder

- Recycled Glass

- Additives

- Packaging Materials

Machine Section or Lines Required:

- Cupola Furnace

- Fiber Forming Line

- Curing Oven

- Cutting & Edge Finishing Lines

- Acoustic Treatment Line

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in mineral wool ceiling tiles manufacturing plant ranges between 40-50%, labor cost ranges between 15% to 20%, and all other costs ranges between 35-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 35-45%, and net profit lie between the range of 15-22% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the mineral wool ceiling tiles manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1 million square ft. of mineral wool ceiling tiles annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, the Knauf Group announced a special partnership between two business groups, Knauf Insulation and Knauf Ceiling Solutions, at their shared location in Illange, Grand Est, France, marking a significant milestone.

- In November 2024, the ROCKWOOL Group's Rockfon North America announced the start of its Rockcycle take-back initiative. By delivering their end-of-life stone wool acoustic ceiling tiles and panels to ROCKWOOL production plants in Mississippi and West Virginia, customers may now fully support their building project sustainability goals.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104