Sea Salt Manufacturing Cost Analysis: Pure Crystals, Clear Costs

What is Sea Salt?

Sea salt is a natural mineral product obtained through the solar evaporation of seawater, followed by harvesting, washing, drying, grading, and packaging. Unlike refined table salt, which undergoes heavy chemical processing, sea salt production relies primarily on solar energy and natural crystallization, allowing it to retain trace minerals such as magnesium, calcium, and potassium that contribute to its distinct taste and nutritional value. In the manufacturing process, seawater is directed into shallow evaporation ponds, where sunlight and wind gradually evaporate the water, leaving behind salt crystals. These crystals are collected at specific stages of evaporation, depending on the desired texture, purity, and grain size, resulting in a wide range of products from coarse and flaky salts to fine-grain varieties used in everyday cooking. The minimal processing involved preserves sea salt’s natural composition and characteristic flavor, making it a preferred choice for both culinary and wellness applications.

Key Applications Across Industries:

Sea salt finds diverse applications across food, personal care, wellness, industrial, and agricultural sectors, valued for its natural origin, texture, and functional versatility. In the food and beverage industry, sea salt is used extensively as a seasoning, preservative, and flavor enhancer. It is incorporated into cooking, baking, snack production, meat and seafood processing, dairy products, sauces, and ready-to-eat foods. Specialty sea salts, such as flaky or coarse varieties, are popular in gourmet and artisanal cuisines as finishing salts, enhancing both the flavor and visual appeal of dishes.

In food processing, sea salt plays essential roles in fermentation, curing, and moisture control. It supports bread making, cheese production, pickling, and meat curing, where it helps improve texture, extend shelf life, and ensure product safety. The presence of naturally occurring minerals also imparts unique taste profiles, making sea salt a key ingredient in premium and clean-label food formulations.

Beyond food, sea salt is widely used in personal care and wellness products. It is a common ingredient in bath salts, body scrubs, soaps, and skincare formulations due to its exfoliating, mineralizing, and detoxifying properties. In spas and therapeutic settings, sea salt is used in mineral baths and relaxation treatments that promote rejuvenation and skin health.

Industrial applications include its use in water softening, textile processing, and chemical manufacturing, where sea salt acts as a raw material or functional additive. In agriculture, it is used in animal feed supplements and soil treatments, contributing essential minerals for livestock nutrition and soil conditioning. The combination of functional benefits, sensory appeal, and natural sourcing underpins sea salt’s wide-ranging use across consumable and non-consumable applications worldwide.

What the Expert Says: Market Overview & Growth Drivers

The global sea salt market reached a value of USD 19.49 Billion in 2024. According to IMARC Group, the market is projected to reach USD 27.12 Billion by 2033, at a projected CAGR of 3.7% during 2025-2033. The global sea salt market is expanding steadily, fueled by growing consumer demand for natural, minimally processed, and premium food ingredients. One of the primary market drivers is the clean-label movement, as consumers increasingly prefer authentic products with minimal additives. Sea salt’s image as a pure, naturally sourced alternative to refined salt aligns perfectly with this trend, driving its adoption across household and foodservice segments.

The growth of the food and beverage industry further supports demand. The expansion of processed and packaged foods, along with the globalization of culinary culture, has increased the need for consistent, high-quality salt products. Meanwhile, the rise of gourmet and artisanal foods has boosted interest in specialty sea salts that offer unique textures, mineral profiles, and regional provenance.

In the wellness and personal care industries, growing interest in natural and holistic self-care is driving sea salt usage in bath, spa, and skincare products. Its association with relaxation, detoxification, and mineral replenishment enhances its appeal in the wellness segment.

Urbanization and rising disposable incomes, particularly in emerging markets, are also fueling higher consumption of packaged foods and personal care products, indirectly increasing sea salt demand. The growth of hospitality, tourism, and fine dining sectors further reinforces this trend, as sea salt is often featured in premium food experiences. On the supply side, advancements in harvesting, washing, drying, and grading technologies have improved product quality and hygiene without compromising natural characteristics. Many producers are also focusing on origin-based branding, traceability, and sustainability certifications to differentiate their products and build consumer trust.

From an environmental standpoint, sea salt manufacturing is considered eco-efficient, relying primarily on solar evaporation and requiring minimal energy compared to refined salt production. Collectively, these factors like natural ingredient demand, food industry growth, wellness trends, premiumization, and sustainable production methods continue to drive steady global growth in sea salt manufacturing and value-added applications.

Case Study on Cost Model of Sea Salt Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale sea salt manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed sea salt manufacturing plant in India. This plant is designed to manufacture 20,000 tons of sea salt annually.

Manufacturing Process: The manufacturing process of sea salt relies on natural solar evaporation, supported by controlled harvesting and post-processing operations to ensure high purity, consistency, and mineral retention. The process begins with the intake of clean seawater, which is channeled into a network of shallow evaporation ponds located near coastal regions. These ponds are specially engineered to maximize exposure to sunlight and wind, allowing for gradual and efficient water evaporation. As the seawater passes sequentially through multiple ponds, the salinity increases at each stage, while suspended impurities and sediments settle naturally at the bottom.

When the brine reaches the desired concentration, it enters the crystallization ponds, where salt crystals begin to form. The timing of harvesting is crucial as crystal size, shape, and mineral composition vary depending on environmental conditions, evaporation rate, and temperature. Once the optimal level of crystallization is achieved, the salt is harvested either mechanically or manually, depending on production scale and intended product type. Premium varieties, such as fleur de sel, are traditionally hand-harvested from the surface layer, preserving their delicate crystal structure and unique flavor profile.

Following harvesting, the raw sea salt undergoes a washing stage to remove residual brine, sand, and organic materials. The cleaned salt is then dried using either solar drying beds or low-temperature mechanical dryers to reduce moisture content and stabilize the product. Drying parameters are carefully controlled to maintain the salt’s natural mineral composition and prevent discoloration or caking. Once dried, the salt is graded and sieved into various particle sizes, ranging from fine-grain table salt to coarse crystals and industrial grades, depending on end-use requirements. Each batch undergoes quality control testing to verify purity, moisture level, and compliance with food safety and hygiene standards.

Finally, the finished sea salt is packaged in moisture-resistant containers or bags to preserve freshness and prevent clumping during storage and transportation. The entire process emphasizes natural energy utilization, minimal chemical intervention, and environmental sustainability, resulting in a product that retains the trace minerals and distinctive flavor characteristics inherent to naturally evaporated sea salt.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

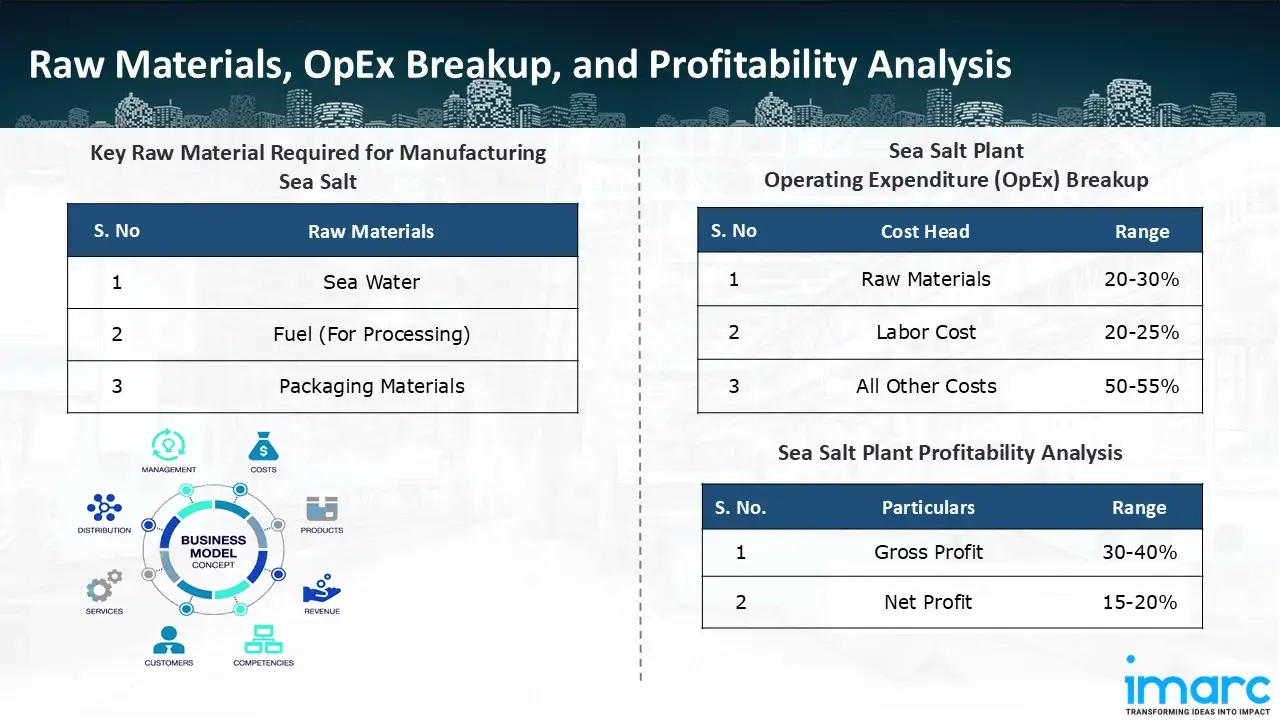

The basic raw materials required for sea salt manufacturing include:

- Sea Water

- Fuel (For Processing)

- Packaging Materials

Machine Section or Lines Required:

- Evaporation Ponds

- Washing

- Drying

- Iodization

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in sea salt manufacturing plant ranges between 20-30%, labor cost ranges between 20% to 25%, and all other costs ranges between 50-55% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 15-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the sea salt manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 20,000 tons of sea salt annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2025, Cornish Sea Salt, known for its premium salty seasonings, has unveiled a bold new addition to its portfolio: Spicy Margarita Sea Salt. Cornish sea salt, jalapeño, sugar, red bell pepper granules, chilli powder, and natural citrus flavourings are all combined in the Spicy Margarita Sea Salt.

- In June 2025, Morton Salt (also known as SCIH Salt Holdings Inc.) announced that its Consumer sector will greatly expand its production capacities to improve consumer dependability throughout North America.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104