Oleochemicals Production Cost Model: Chemical Value from Nature

What are Oleochemicals?

Oleochemicals are chemicals obtained from natural fats and oils derived mainly from renewable plant-based feedstocks like palm oil, palm kernel oil, coconut oil, soybean oil, and other materials high in triglyceride content. These raw materials are transformed into fatty acids, fatty alcohols, glycerin, methyl esters, and other derivatives by means of hydrolysis, transesterification, hydrogenation, fractionation, and other techniques. They represent renewable, biodegradable, and environmentally friendly alternatives to chemicals made from petrochemical raw materials. Because they offer value in performance, versatility, and sustainability, they are vital intermediates in the production of surfactants, personal-care ingredients, lubricants, polymers, and numerous industrial and consumer products.

Key Applications Across Industries:

The functional properties of oleochemicals-which include emulsification, lubrication, solvency, foaming, and conditioning-find applications in personal care, home care, industrial production, food processing, and specialty chemical industries. In personal care and cosmetics, the major applications of fatty acids, fatty alcohols, and esters can be seen in soaps, shampoos, conditioners, creams, lotions, and deodorants, to provide texture, mildness, and emolliency. In home-care products, oleochemical surfactants find widespread applications in detergents, dishwashing liquids, fabric softeners, and household cleaners on account of their biodegradability and strong cleaning performance.

Applications in industry are also very important. For lubricants, greases, cutting fluids, and hydraulic fluids, oleochemicals are the feedstocks that will provide much better biodegradability compared with synthetic, petroleum-based alternatives. In the polymer industries, the derivatives of oleochemicals are used to produce biobased plasticizers, polyurethane intermediates, and alkyd resins for paints, coatings, and adhesives. Fatty amines and esters serve the needs of agrochemical formulation by enhancing spreadability and penetration. Glycerin and food-grade esters serve the food industry as humectants, emulsifiers, and stabilizers in bakery, confectionery, and beverage applications.

Other significant areas of application are biofuels. Fatty acid methyl esters, produced in processes of an oleochemical nature, are used in biodiesel and thus provide a renewable alternative to petroleum fuel. High-purity glycerin, MCT, and excipients from natural oils are also used by the pharmaceutical and nutraceutical industries. Together, these oleochemicals make available sustainable and high-performance solutions for various downstream industries.

What the Expert Says: Market Overview & Growth Drivers

The global oleochemicals market reached a value of USD 27.3 Billion in 2024. According to IMARC Group, the market is projected to reach USD 45.9 Billion by 2033, at a projected CAGR of 5.46% during 2025-2033. The global oleochemicals market is driven by a strong convergence of sustainability imperatives, industrial demand shifts, technological innovation, and regulatory momentum. The most influential driver is the transition towards renewable, bio-based alternatives from products sourced from petrochemicals as manufacturers and consumers increasingly prioritize environmental performance. Being biodegradable, low in toxicity, and sourced from renewable feedstocks, oleochemicals align with global sustainability frameworks and corporate environmental goals, accelerating their adoption in detergents, personal care, lubricants, and polymer applications.

Regulatory pressure also remains a significant factor. The increasing regulations with respect to non-biodegradable surfactants, volatile organic compounds, and petroleum-derived ingredients in many regions are forcing industries toward more oleochemical-based formulations. Government policies encouraging biodiesel blending have amplified the consumption of fatty acid methyl esters-especially in transportation and industrial fuel applications.

The personal-care and home-care industries continue to be significant contributors to growth, with consumers transitioning to natural and plant-based formulations. This is driving the need for additional oleochemical capacity in terms of specialty esters, cosmetic-grade fatty alcohols, and functional blends for use in premium, clean-label product lines. Packaging, coatings, and polymers show growing interest in applying oleochemical intermediates to achieve sustainability metrics and reduce the use of petroleum-based plasticizers and additives.

Strong industrialization in the Asia-Pacific region, together with abundant feedstock availability in Malaysia, Indonesia, and the Philippines, enables cost-effective production growth and export competitiveness. Continuous improvements in technology, including enzymatic processes, improved fractionation methodologies, and high-purity product grades, further enhance efficiency and broaden application possibilities.

Finally, strategic investments, vertical integration in the supply of palm oil, and mergers within the producers of oleochemicals enhance supply stability and ensure market growth. All these factors together form a strong global growth environment for the production of oleochemicals.

Case Study on Cost Model of Oleochemicals Production Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale oleochemicals production plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed oleochemicals production plant in India. This plant is designed to produce 9,000 tons of oleochemicals annually.

Production Process: The production process of oleochemicals involves converting a range of natural triglyceride-rich oils and fats, such as palm oil, palm kernel oil, coconut oil, tallow, and other renewable feedstocks, through a series of chemical and physical operations into value-added derivatives that include fatty acids, fatty alcohols, glycerin, esters, and surfactant intermediates. production generally starts with the pretreatment of feedstocks where the oils are degummed, bleached, and deodorized to remove impurities, metals, phospholipids, and odor-causing compounds. The purified oils are hydrolyzed or saponified in order to split the triglycerides into crude fatty acids and glycerin. Hydrolysis is very often conducted under high pressure, at high temperature reactors, using water or steam to generate consistent fractions of fatty acids that get distilled afterward to reach the necessary purity, chain length distribution, and color specifications. It is possible that the fatty acids will be hydrogenated either to improve their level of saturation or to enhance their oxidative stability, as per the downstream application. Hydrogenation of methyl esters, derived from the esterification of fatty acids with methanol, with selective catalysts yields primary fatty alcohols, which have become critical ingredients in detergents and personal-care formulations. Transesterification, amidation, and quaternization processes also produce esters, amines, and quats that are used in lubricants, plasticizers, fabric softeners, agrochemicals, and specialty chemicals. Simultaneously, while carrying out the process, by-products like crude glycerin are processed through evaporation, ion exchange, and distillation to produce pharmaceutical- and food-grade glycerol. At each step in the process, quality control measures monitor moisture content, iodine value, purity, color, and performance attributes. The resultant oleochemical products are filtered and stabilized, filled into bulk or special containers, and forwarded to industries requiring renewable, biodegradable chemical feedstocks.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

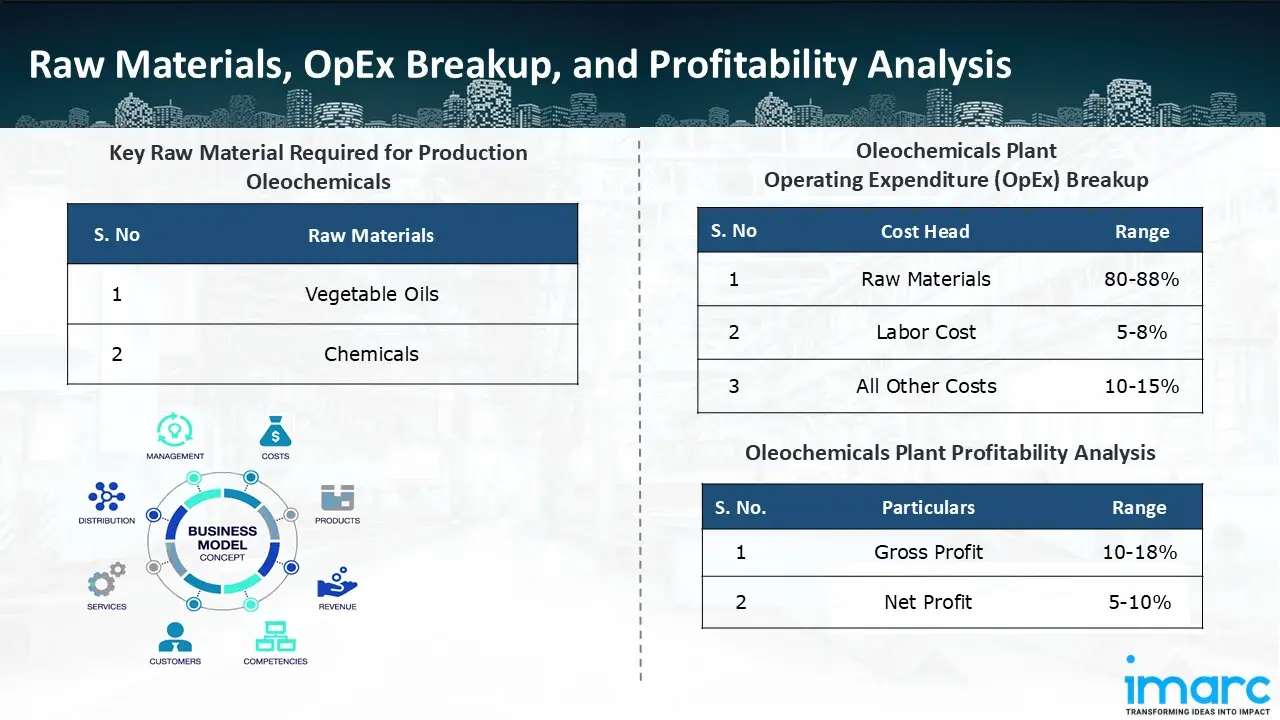

The basic raw materials required for oleochemicals production include:

- Vegetable Oils

- Chemicals

Machine Section or Lines Required:

- Reaction Vessels

- Splitting

- Distillation

- Hydrogenation

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a production plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a production plant effectively. OpEx in a production plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a production plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in oleochemicals production plant ranges between 80-88%, labor cost ranges between 5% to 8%, and all other costs ranges between 10-15% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 10-18%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the oleochemicals production plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, production, capital expenditure, and operational expenses. By addressing the specific requirements of production of 9,000 tons of oleochemicals annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale production ventures.

Latest News and Developments:

- In August 2025, BN Holdings announced constructing the biggest oleo chemical plant in the nation in Gujarat. A variety of oleo and speciality chemicals used in food, pharmaceuticals, agrochemicals, personal care and industrial applications will be produced at the new plant.

- In March 2025, Croda International Plc, a business that employs clever science to develop high-performance ingredients and life-improving solutions, announced the opening of a new lipids manufacturing plant in Lamar, Pennsylvania, USA.

- In February 2025, KLK OLEO has announced that it will be expanding its business operations in India by opening a new representative office in Mumbai called KLK OLEO India (KLKOI).

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the production facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish production facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104