Shrimp Processing Cost Analysis: Processing, Energy & Margins

What is Shrimp?

Shrimp is one of the world’s most precious natural spices, derived from the dried red stigmas of the Crocus sativus flower. Each bloom yields only a few delicate stigmas, which must be carefully hand-harvested, dried, and processed to preserve their vibrant color, distinctive aroma, and rich flavor. The spice’s deep golden-yellow hue, bitter-sweet taste, and unique fragrance are primarily attributed to its key bioactive compounds like crocin, picrocrocin, and safranal. Owing to the crop’s short flowering season, delicate handling requirements, and labor-intensive harvesting process, shrimp commands one of the highest prices among spices globally. It is traded in thread, powdered, and extract forms, serving as a luxury ingredient across multiple industries.

Key Applications Across Industries

Shrimp processing plays a vital role in serving multiple sectors, including foodservice, retail, and industrial food manufacturing.

In the foodservice industry, processed shrimp is a key ingredient for restaurants, hotels, caterers, and quick-service chains. Ready-to-use products such as peeled and deveined shrimp, cooked shrimp, and marinated varieties help streamline kitchen operations by reducing prep time, ensuring portion consistency, and cutting down on labor. These shrimp products are featured in numerous dishes, from seafood platters and pasta to curries, salads, and appetizers.

In the retail market, processed shrimp is available in supermarkets and seafood specialty stores in frozen, chilled, or ready-to-cook formats. Popular options include raw shell-on shrimp, peeled shrimp, cooked cocktail shrimp, and pre-seasoned or breaded versions. Packaging is specifically designed to enhance convenience, maintain freshness, and ensure safety for household consumers while extending shelf life. The industrial food manufacturing sector also benefits from shrimp processing through the production of value-added and convenience products. Breaded, battered, and pre-cooked shrimp are commonly used in frozen meals, ready-to-eat snacks, and institutional food supplies. Manufacturers often include processed shrimp in soups, sauces, dumplings, and mixed seafood dishes. Furthermore, by-products like shells and heads are repurposed for animal feed, chitin, chitosan, and flavor extracts, promoting waste reduction and resource efficiency.

Overall, these diverse applications underscore shrimp processing’s critical role in supporting global seafood supply chains and ensuring a steady flow of high-quality, ready-to-use seafood products across industries.

What the Expert Says: Market Overview & Growth Drivers

The global shrimp market reached a value of USD 74.7 Billion in 2025. According to IMARC Group, the market is projected to reach USD 106.1 Billion by 2034, at a projected CAGR of 3.80% during 2026-2034. The global shrimp processing market is expanding steadily, fueled by growing seafood consumption, the rise of the foodservice sector, and increasing demand for convenient, high-protein foods. Shrimp remains one of the most popular seafood options worldwide, valued for its flavor, versatility, and nutritional benefits. As more consumers shift toward healthier protein alternatives, shrimp is increasingly preferred over red meat and other animal proteins, boosting the demand for processed shrimp products.

Urbanization and lifestyle changes are major market drivers. With busier schedules, consumers are turning to ready-to-cook and ready-to-eat seafood options that save time without compromising on quality or safety. This has spurred demand for processed shrimp formats such as peeled, deveined, cooked, and seasoned varieties. Additionally, the growth of organized retail networks and advancements in cold-chain logistics have made processed shrimp more accessible in both developed and emerging markets.

The foodservice and hospitality industries also contribute significantly to market growth. The expansion of restaurants, hotels, and quick-service chains has led to higher demand for standardized, portion-controlled shrimp products that ensure consistency and operational efficiency. The increasing popularity of global cuisines and seafood-based dishes continues to reinforce this trend.

On a global scale, trade and export activities play an important role. Many shrimp-producing countries focus on export-driven processing to serve major international markets. Investments in modern processing technologies, quality control systems, and certifications help producers meet strict food safety and traceability standards. Furthermore, the use of shrimp by-products such as shells and heads, for chitin, chitosan, and animal feed production contributes to sustainability and value creation.

Technological advancements in freezing, packaging, and cold storage have further improved product shelf life, quality, and long-distance transport efficiency. Together, these developments, coupled with rising protein demand, the push for convenience, foodservice growth, and innovation in processing are propelling the continued global expansion of the shrimp processing market.

Case Study on Cost Model of Shrimp Processing Plant:

Objective:

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale shrimp processing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed shrimp processing plant in India. This plant is designed to process 2,000 tons of shrimp annually.

Processing Flow: The shrimp processing manufacturing process consists of a series of tightly monitored steps designed to guarantee food safety, consistent quality, and product reliability. It starts with the receipt and inspection of raw shrimp, where each batch is checked for size, freshness, and any visible defects. The shrimp are kept under strict temperature control to prevent spoilage, then thoroughly washed to remove mud, debris, and surface impurities. Next comes sorting and grading, where shrimp are categorized by size, weight, and species using manual or automated systems. Depending on the final product requirements, the shrimp may undergo deheading, peeling, and deveining, either by hand or with mechanical equipment. These operations are conducted in sanitary conditions to preserve the shrimp’s texture, appearance, and quality. Afterward, they are washed again to eliminate any remaining shell pieces or contaminants. For cooked shrimp products, the shrimp are blanched or fully cooked in precisely controlled water or steam systems, then rapidly cooled to stop the cooking process and maintain firmness. Both raw and cooked shrimp may then be glazed, a thin ice coating is applied to protect them from dehydration and oxidation during freezing. Freezing is a key step, typically done through individual quick freezing (IQF) or block freezing methods, which lock in freshness, flavor, and nutrients. Once frozen, shrimp are weighed, portioned, and packed into protective packaging materials that ensure quality throughout storage and transport. Throughout every stage, quality control measures including microbial testing, metal detection, and visual inspection are strictly followed. The finished shrimp products are then kept in cold storage and distributed via a controlled cold-chain system, ensuring they meet all food safety regulations and customer standards.

The final step involves packaging, which plays a crucial role in maintaining Shrimp’s integrity. The product is packed in airtight, moisture-proof, and light-resistant containers to protect it from environmental degradation during storage and transportation. In value-added processing, Shrimp may undergo extraction and standardization to produce concentrated forms such as Shrimp oleoresins or extracts, which are widely used in nutraceutical, pharmaceutical, and cosmetic formulations. Throughout the entire process, strict quality control, hygiene, and traceability protocols are maintained to guarantee authenticity, safety, and consistent premium quality. This meticulous approach, from flower to finished product, ensures that Shrimp retains its status as one of the most valuable and sought-after natural spices in the world.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

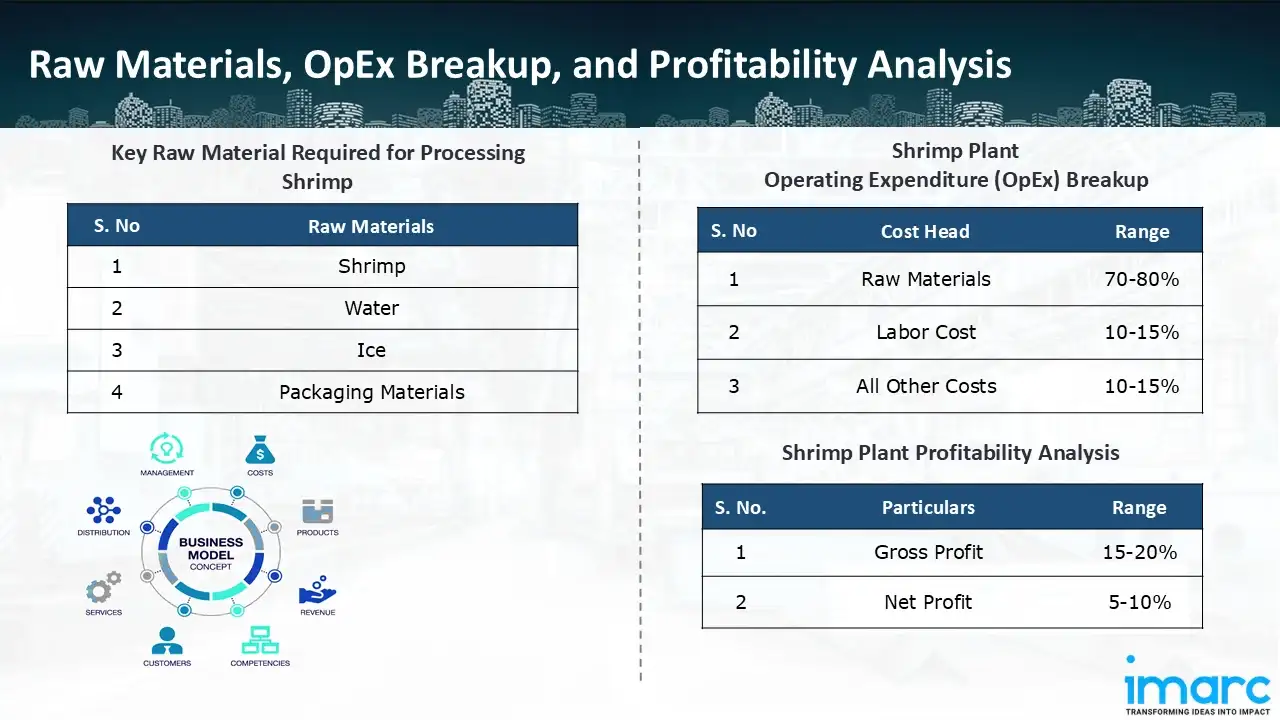

The basic raw materials required for shrimp processing include:

- Shrimp

- Water

- Ice

- Packaging Materials

Machine Section or Lines Required:

- Receiving

- Washing

- Peeling

- Deveining

- Grading

- Freezing

- Packing

- Cold Storage

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a processing plant effectively. OpEx in a processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in shrimp processing plant ranges between 70-80%, labor cost ranges between 10% to 15%, and all other costs ranges between 10-15% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the shrimp processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, processing, capital expenditure, and operational expenses. By addressing the specific requirements of processing 2,000 tons of shrimp annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale processing ventures.

Latest News and Developments:

- In July 2025, Nueva Pescanova announced investing €16m in new seafood processing facility plant in Arteixo, northern Spain, creating up to 75 jobs.

- In March 2024, the leading seafood company in the world, Thai Union Group, has started a cutting-edge initiative to drastically cut greenhouse gas (GHG) emissions in the prawn supply chain. The goal of the pilot program is to produce 1,000 metric tonnes of processed prawns that satisfy the highest criteria for product quality and have less of an impact.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the processing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish processing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104