Organic Fertilizer Production Cost Model: Biofertilizer Economics

What is Organic Fertilizer?

Organic fertilizers refer to nutrient-value-adding materials that come from ecologically degradable sources like plant debris, animal manure, composted materials, bio-wastes, bone meal, and microbe organisms. Another key point of distinction between organic and synthetic fertilizers is that whereas synthetic fertilizers give quicker nutrient release through chemical reactions, nutrient release occurs via bacterial decomposition in the case of organic fertilizers. Organic fertilizers are required for practicing sustainable agriculture to nourish the soil and maintain its good health for increasing water retention and establishing well-proportioned plants without harming the environment by chemical addition of fertilizers to the environment.

Key Applications Across Industries:

Organic fertilizers have a broad application in agriculture, horticulture, land scape, and specialized agri-systems. In agriculture, their uses include enhancement of soil fertility in cereal, pulse, oilseeds, and fodder crops. It is done by increasing the organic matter in the soil, thus encouraging beneficial soil microbes. Since it is a slow-release fertilizer, it reduces crop reliance on frequent supplementation of fertilizers in agriculture.

In agriculture, organic fertilizers have an important function in vegetable and fruit cultivation due to their enhancement of soil texture and nutrient uptake efficiency. Vegetable and fruit crops will also have improved nutritional and quality aspects due to organic fertilizers. The organic fertilizers will also play a central role in organic farms that do not use any kind of artificial fertilizers.

Landscaping, lawn management, and home gardening are other usages. Organic fertilizers and biofertilizers are applied to lawns, gardens, nurseries, and even urban greens in lawn landscaping and home gardening. The purpose is to encourage healthy plant growth while establishing ecological balance. Other usages include the application of organic fertilizers in floriculture and green houses.

Specialized crops include plantation crops like tea, coffee, spices, and plantation forestry. Soil sustainability for the long term is very important in this sector. Organic fertilizer is also part of integrated nutrient management. These types of fertilizer are used alongside mineral fertilizer to make nutrient management more effective. They can be used in small-scale farming as well as in big agricultural enterprises.

What the Expert Says: Market Overview & Growth Drivers

The global organic fertilizer market reached a value of USD 8.69 Billion in 2024. According to IMARC Group, the market is projected to reach USD 22.60 Billion by 2033, at a projected CAGR of 11.20% during 2025-2033. The organic fertilizer market has been fueled by a growing focus on sustainable agricultural practices and soil management. The most significant driving force for this market is the growing awareness among consumers about the ill effects of using high amounts of chemical fertilizers. The ill effects include soil degradation, groundwater pollution, and a decrease in crop productivity. Governments and agricultural research institutions have turned to organic fertilizers for sustainable agricultural practices.

Growing demand from consumers for organic food products also has a major role in boosting the demand for organic fertilizers in agriculture. This is because consumers are becoming increasingly health and safety conscious while making their purchases from supermarkets or grocery stores. Therefore, they tend to promote organic farming practices being practiced by farmers.

Encouraging government policies and incentive schemes fuel further market expansion. Subsidies and training activities in many countries support organic farming and help adopt organic inputs. Moreover, regulations on waste management practices have spurred on the use of agricultural residues and other waste, such as food and animal by-products, for composting and biofertilizer production, hence supporting a circular economy approach.

Advances in technology related to composting, vermiculture technology, microbial inoculants, and nutrient fortification have enhanced the efficiency of organic fertilizers and made them comparable to synthetic fertilizers. In addition, the increasing awareness about the prevention of climate change has led to the adoption of organic fertilizers because they are effective in carbon sequestration and greenhouse gas reduction. At last, but not the least is the increasing use of urban agriculture, horticulture, and landscape gardening and the implementation of integrated nutrient management practices on a global scale, which is increasing the scope related to the use of organic fertilizers.

Case Study on Cost Model of Organic Fertilizer Production Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale organic fertilizer production plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed organic fertilizer production plant in India. This plant is designed to produce 15,000 tons of organic fertilizer annually.

Production Process: The process of manufacturing organic fertilizer includes the organized conversion of organic materials into a stable and nutrient-rich substance that can be used for farming purposes. The process begins with the procurement and separation of organic materials such as animal dung, agricultural rejects, food sector rejects, oilcakes, bone meal, poultry manure, and green materials. The organic materials are pre-treated with shredder machines, size reduction, and the separation of undesired materials to achieve homogeneity. The organic materials are then processed for biodecomposition, which is usually done through composting methods that involve maintaining a set level of moisture, temperatures, aeration, and a ratio of carbon to nitrogen to ensure microbial activities that stabilize the nutrients. In certain manufacturing setups, vermicomposting can also be used; this will entail the use of earthworms to increase the rate of decomposition and the availability of nutrients. On the other hand, anaerobic digestion can also be used to dispose of organic wastes and subsequently produce compostable material through further composting and drying of the digestate if required. After attaining full decomposition, composting will then entail the processing of composted material to make it uniform by curing and then screening out the larger pieces and particles to achieve uniformity and possibly fortifying with nutrients if required. The processed material is then molded into different forms in line with market demand. Granulated or pelletized forms enhance ease of handling, storage, and application simplicity, while powder forms are used for soil incorporation and planting high-value crops. Drying units decrease moisture content to enhance durability and prevent microbial reactivity. Quality control checks, which include analysis of nutrient content, moisture content, microbial safety, and heavy metals, are done throughout the process. Finally, packaging of the organic fertilizer into moisture-containing bags or trucks follows approved health standards for distribution to farmers.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

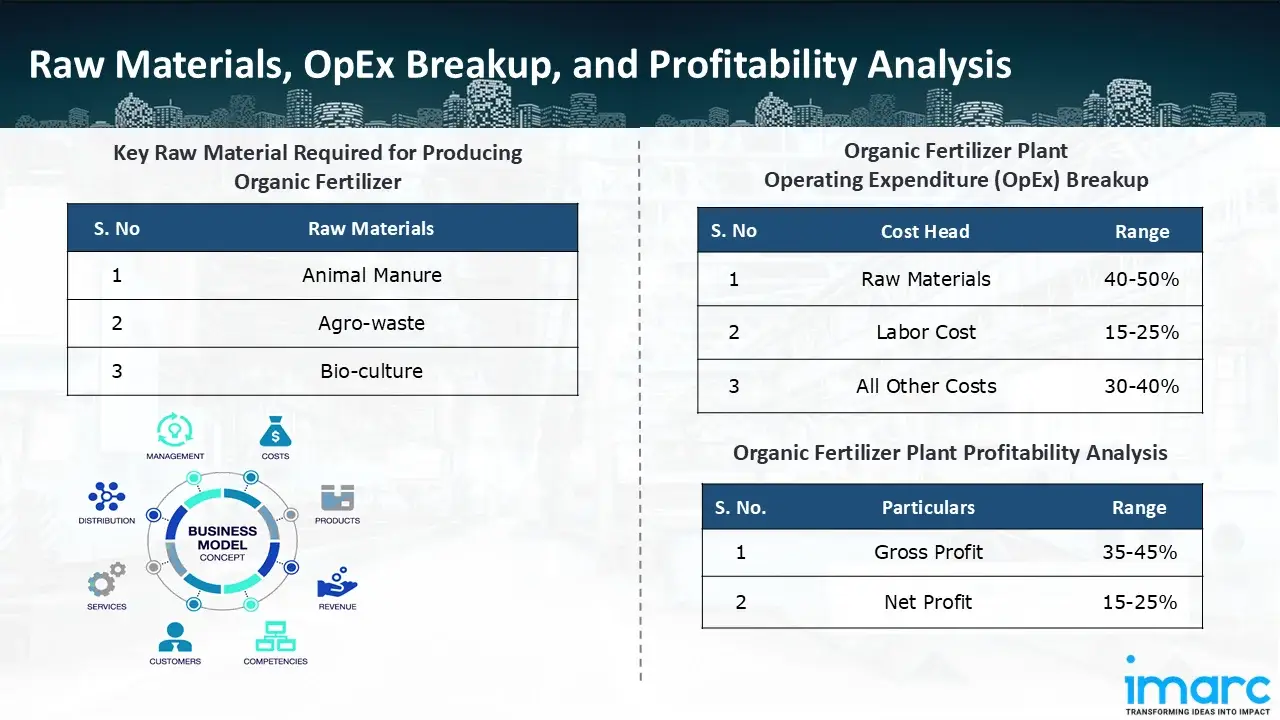

The basic raw materials required for organic fertilizer production include:

- Animal Manure

- Agro-waste

- Bio-culture

Machine Section or Lines Required:

- Shredding

- Composting

- Grinding

- Mixing

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a production plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a production plant effectively. OpEx in a production plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a production plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in organic fertilizer production plant ranges between 40-50%, labor cost ranges between 15% to 25%, and all other costs ranges between 30-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 35-45%, and net profit lie between the range of 15-25% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the organic fertilizer production plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, production, capital expenditure, and operational expenses. By addressing the specific requirements of production of 15,000 tons of organic fertilizer annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale production ventures.

Latest News and Developments:

- In September 2025, Nitricity begins construction of the first-ever organic fertiliser factory in Central California. Through legally binding offtake agreements with organic growers in Central California, the factory has already sold out all of its production capacity through 2028.

- In August 2025, a deal to build a cutting-edge organic fertiliser factory in Kampiringisa, Uganda, has been inked by Itracom Fertilisers Uganda-SMC Ltd.

- In December 2024, Hello Nature has established a new bionutrients facility (U.S.) in Wabash, Indiana. The new 300,000-square-foot facility can generate 150,000 tonnes of organic fertilisers and other biosolutions, mostly using chicken manure from nearby facilities owned by Hello Nature's partner, MPS Egg Farms.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the production facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish production facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104