Paint Manufacturing Cost Analysis: Color Chemistry, Clear Costs

What is Paint?

Paints are liquids, semi-liquids, or powdered materials, usually having a high content of pigments, binders or resins, solvents or vehicles, or additives, intended for application onto substrates to create a continuous film after drying or curing. Paints work as materials after their application, possessing several functionalities, such as protecting the surface, adding color, or modifying functionalities. Paints contain several components, such as binders or resins, pigments, solvents or vehicles, or additives, each differing based on their functionalities. The binder or resin is mainly involved in providing strength or adhesive characteristics, while pigments are used to create colors or opaqueness.

Key Applications Across Industries:

Paints have widespread applications in residential, commercial, industrial, and infrastructure sectors because of their versatile properties. In the residential and commercial sectors, decorative paints are employed to decorate the interior and exterior walls, ceiling, doors, and facade of the building for their aesthetic appeal and ability to provide protection against moisture and sunlight. Architectural paints have also been recognized for their contribution to residential and commercial spaces regarding hygiene and their ability to provide a washable and anti-fungal finish.

Paints have several applications in industry. They are mainly used for protecting machinery, pipelines, storage tanks, automotive parts, and fabricated metal products. In the automotive industry, paints play major roles in both functionality and aesthetics. They provide automotive parts with gloss, color uniformity, and resistance to both environmental and mechanical factors. Paints can also be used for several other applications in different industries depending on their properties.

Infrastructure developments require heavily specialized paints for bridges, roads, railways, airports, and ships. Protection and anti-corrosion paints defend steel and concrete investments against severe environmental conditions. In the shipbuilding industry, paints serve purposes of protection, fouling prevention, and prevention of corrosion. The aerospace industry employs special paints that act as protective materials to achieve lightweight protection.

Paints are also used in consumer products, furniture, appliances, packaging, and electronics for the purpose of branding, surface treatment, and functional applications like insulation or conductivity. The new uses of paints include heat-reflective paints, antimicrobial paints, fire-resistant paints, and eco-friendly water-based paints, which even further broaden the applications of paint.

What the Expert Says: Market Overview & Growth Drivers

The global paint and coatings market reached a value of USD 183.3 Billion in 2024. According to IMARC Group, the market is projected to reach USD 268.3 Billion by 2033, at a projected CAGR of 4.3% during 2025-2033. The paints industry is spurred by various factors, including growth in the construction industry, growth in industries, urbanization, and technological developments. Some of the main driving forces in the paints industry are the growth and development in various forms of construction, including housing and infrastructure, around the world. Various housing developments, renovation, and infrastructure development are some of the main factors that drive the demand for various paints around the world. Emerging nations are also driving urbanization around the world.

Industrial expansion is another major influence. The manufacturing industry, including automotive, aerospace, ship building, oil and gas, and heavy engineering, requires specialty coating solutions for protection against corrosion, durability, and performance enhancement. Due to the increasing complexity levels of industrial assets and the more demanding operating conditions, the need for advanced coating solutions has continued to rise.

Consumer behavior is also affecting market dynamics. With increased disposable income and awareness about aesthetics, there is an inclination among homeowners and enterprises to invest in high-end finishes, coloring, and performance-enhanced paints. The rise of the do-it-yourself culture and availability of home improvement stores is also encouraging, especially with regards to easy-to-use, low odor, and fast-dry paints.

Regulatory and environmental factors are an important influencing factor in the market. Strict regulations surrounding volatile organic compounds (VOCs) have contributed greatly towards the increase in the use of water based, low-VOC, and environmentally friendly paint. This, in turn, triggers an innovation and replacement cycle. Furthermore, the rising concern regarding sustainability and energy conservation is currently fueling the trend of heat-reflective, insulating, and long-lasting coatings.

Advances in technology for resin chemistry formulation and pigment and additive functionality improve the durability and weatherability of paints. While the factors driving the market for the manufacture of paints are many and complicated, this explanation attempts to simplify the process due to its complexity.

Case Study on Cost Model of Paint Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale paint manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed Paint manufacturing plant in India. This plant is designed to manufacture 1,500 kilo litre of paint annually.

Manufacturing Process: Paint manufacture is a series of carefully controlled steps aimed at dispersing solid color pigments evenly in a liquid binder component and forming a stable, efficient paint product. Paint manufacture starts with raw material selection, such as color and opacifying pigments, binders and resins, film formation and adhesion, solvents and water, and functional additives that improve flow, dry times, and erosion resistance. Paint manufacture begins with premix, where there is a mix of color pigments, a proportion of binders, solvents, and wetting agents using high-speed dispersors, also referred to as mixie masalas, where a homogenous pigment mix is obtained. Following this, grinding or dispersion ensues. It is an important step in disintegrating pigment agglomerates with respect to pigment particle size and light fastness. The process is done with machinery like bead mills, ball mills, or sand mills. Later in the process, paint is moved to the so-called let-down stage. It is accomplished as binders, solvents, and other additives are added with regard to viscosity, application ability, as well as other features. The resulting paint formula undergoes a filtration process to eliminate any contaminants and/or particles that are too large in size, thereby resulting in smooth paint application and final finishes. The quality control tests are performed at various levels to check the color accuracy, viscosity, drying time, adhesion, gloss, and the resultant paint stability. The approved samples of paint are then packed in separate containers using automated machines. In this process, manufacturers adhere strictly to safety, environmental, and quality guidelines and increasingly turn to waterborne systems, closed-loop solvent management, and automated processing to become more efficient, reduce their emissions, and produce consistent quality output.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

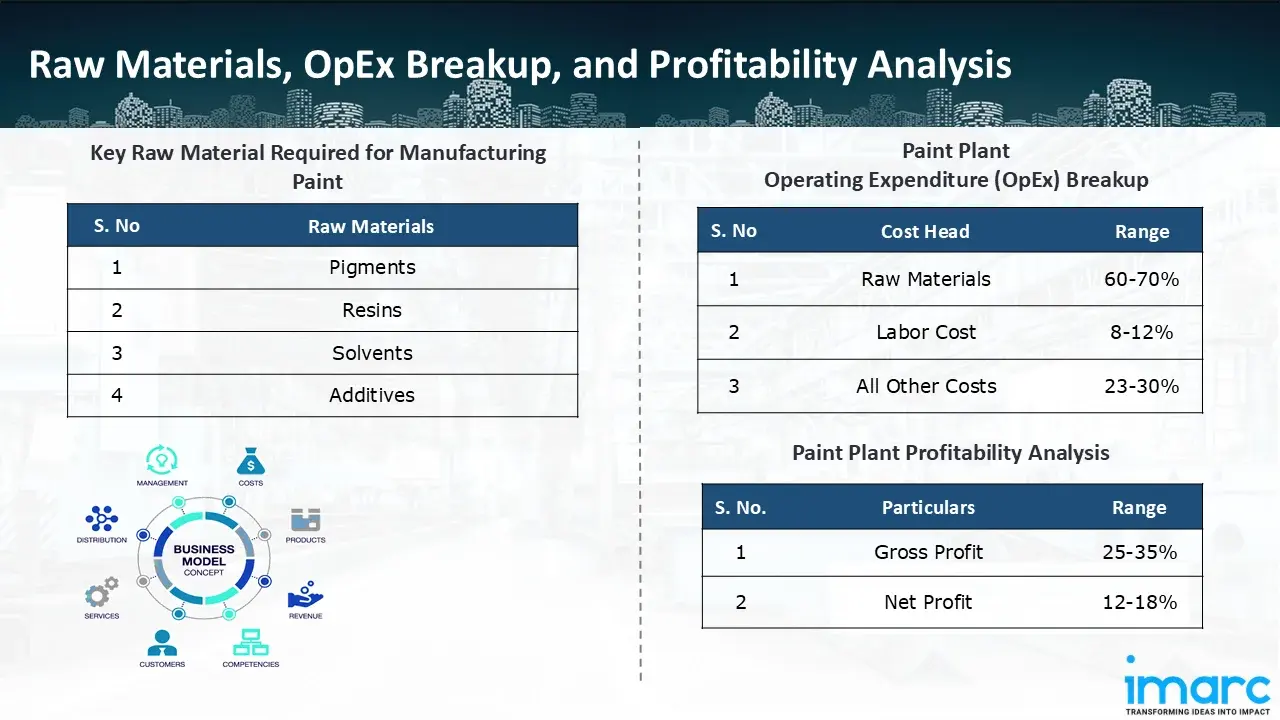

The basic raw materials required for paint manufacturing include:

- Pigments

- Resins

- Solvents

- Additives

Machine Section or Lines Required:

- Resin Plant

- Sand Mill

- High-Speed Disperser

- Filling

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in paint manufacturing plant ranges between 60-70%, labor cost ranges between 8% to 12%, and all other costs ranges between 23-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-35%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the paint manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1,500 kilo litre of paint annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2025, JSW Paints has successfully acquired a 61.2% share in Akzo Nobel India from Akzo Nobel N.V. and its affiliates. Akzo Nobel India, which is well-known for products like Dulux, offers a robust range of industrial and consumer coatings.

- In September 2025, Asian Paints declared that it would invest between INR 1,500 and INR 2,000 crore to establish a new greenfield factory in Indore, Madhya Pradesh. Asian Paints is building its ninth factory, which would increase the company's total capacity to 26 lakh kilolitres by producing 4 lakh kilolitres of water-based paint annually.

- In August 2024, Berger Paints announced its plans to invest about Rs 2,000 crore in two greenfield projects, one in Bengal and the other in Odisha to increase its total manufacturing capacity by between 25–30%. Berger has a monthly output capacity of one lakh million tonnes.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104