Cement Market Trends: Powering Global Construction, Green Materials, and Smart Manufacturing

Introduction:

The cement industry remains one of the most critical foundations of global development, shaping the built environment and enabling progress across residential, commercial, and industrial landscapes. As construction activity expands and infrastructure investment intensifies, the cement market size continues to evolve, supported by new material innovations, sustainability priorities, and smart manufacturing technologies. The global cement market plays a defining role in strengthening economic productivity, supporting megacities, and providing the essential binding material for large-scale structures.

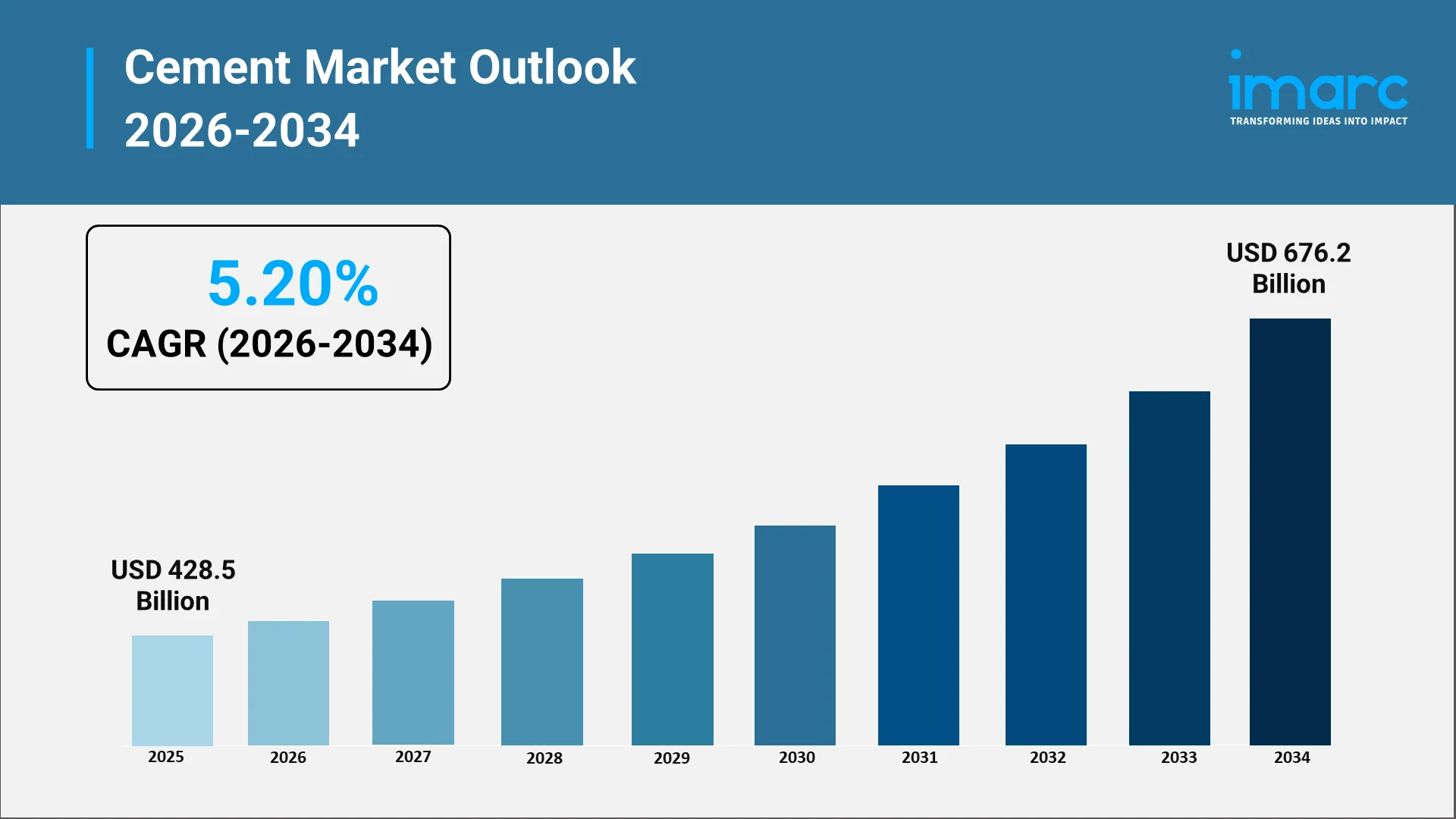

At its core, the industry influences nearly every dimension of modern construction. The global cement market size was valued at USD 428.5 Billion in 2025, and is projected to reach USD 676.2 Billion by 2034, growing at a CAGR of 5.20% during 2026–2034, underscoring the sector’s expanding economic footprint. From highways and bridges to renewable energy projects, industrial plants, and urban housing, cement stands as a universal building material. The ongoing cement market analysis highlights how shifting population centers, urban restructuring, and sustainability goals are reshaping consumption patterns and industrial strategies. By powering massive infrastructure upgrades, accelerating construction workflows, and enabling durable architecture, the cement sector supports broader development targets for nations worldwide.

Beyond construction growth, innovation in cement production is answering urgent environmental and efficiency challenges. Companies are exploring low-carbon materials, circular production processes, and advanced clinker substitutes. At the same time, automation and digitalization are transforming manufacturing through real-time monitoring, predictive maintenance, and optimized resource consumption. These advancements are reflected throughout the world cement market, where producers are balancing rising demand with a commitment to sustainable practices.

Explore in-depth findings for this market, Request Sample

Key Industry Trends:

Surging Infrastructure Investment in Emerging Economies

One of the most influential drivers shaping the cement market trends is the surge in infrastructure development across emerging economies. Many countries are undergoing rapid urbanization, expanding their transportation networks, and investing in logistics, public utility systems, and modern industrial corridors. In 2025, Heidelberg Materials announced that a global infrastructure boom is set to significantly boost its operating profit through 2030, driven by heightened demand from large construction and public works projects. These national and regional development programs rely heavily on cement for constructing rail corridors, highways, energy plants, water systems, urban transit lines, and commercial hubs.

The growth patterns in these nations directly impact the cement market share, as expanding cities require diversified cement grades to support complex structural needs. As infrastructure becomes a central economic strategy, governments and private players seek durable, high-performance materials that can withstand heavy use and environmental variations. This sustained expansion continues to be a major pillar of the global cement market, reinforcing its role as a strategic material for long-term growth.

Shift Toward Low-Carbon and Green Cement Technologies

Sustainability has become a defining theme in the modern cement industry. Producers are transitioning from traditional production models toward innovative low-carbon processes, alternative fuels, and sustainable raw material pathways. This shift reflects the growing emphasis on reducing emissions, conserving natural resources, and creating environmentally responsible building materials.

Green cement technologies focus on reducing clinker usage, optimizing thermal efficiency, and incorporating industrial byproducts such as fly ash, slag, and calcined materials. In 2025, Heidelberg Materials launched a first-of-its-kind carbonation facility in Poland (Górazdze plant) that uses recycled concrete paste and kiln exhaust gases to chemically bind CO2 — permanently trapping 100–150 kg of CO2 per tonne of recycled paste, while avoiding up to 850 kg of emissions otherwise released during clinker production. These innovations support the global movement toward sustainable construction while helping the industry align with environmental targets and green building certification requirements. As a result, the cement market report highlights low-carbon cement as one of the most transformative developments in recent years, reshaping product portfolios and future investment priorities.

Rising Demand from Residential and Commercial Construction Boom

Around the world, rising household formation, rapid urban migration, and growing commercial development continue to drive cement demand. Residential construction, including affordable housing, premium homes, and multi-story apartments, remains a major market contributor. In India, for example, the Pradhan Mantri Awas Yojana (PMAY) urban scheme handed over more than 9.06 million homes to slum-area beneficiaries as of March 2025 — a major boost for cement consumption in urban housing. Parallel to this, office spaces, retail centers, healthcare facilities, and educational institutions add to the sector’s expansion.

This construction boom reflects changing lifestyles, expanding economic opportunities, and the modernization of urban centers. Developers increasingly seek materials that ensure structural strength, durability, and efficient construction timelines. As a result, the building sector forms a substantial portion of the cement market size, cementing its importance in shaping urban architecture and regional growth.

Integration of Digital and Smart Manufacturing in Cement Plants

Digitalization is transforming cement manufacturing into a more efficient, predictive, and data-driven process. Modern plants leverage automation, advanced sensors, AI-powered quality control systems, and digital twins to optimize operations and reduce manual intervention. For example, Holcim launched the world’s first cement plant digital twin in Switzerland, combining real-time 3D modelling with predictive analytics to prevent downtime, optimize energy use, and improve safety. These smart manufacturing systems improve energy management, ensure consistency in cement quality, and enhance safety across the value chain.

Industrial automation is also supporting real-time decision-making. Predictive analytics help reduce downtime while smart logistics systems streamline inventory, dispatch, and distribution. This digital transformation marks a major shift in the cement market analysis, ensuring that producers remain competitive while meeting rising demand with greater precision and sustainability.

Growth of Ready-Mix and Pre-Cast Concrete as Value-Added Routes

Ready-mix concrete (RMC) and pre-cast components have emerged as vital extensions of the cement industry, offering enhanced efficiency and material consistency for construction projects. These value-added products support faster construction cycles, reduce onsite labor requirements, and ensure improved quality control.

RMC is increasingly preferred in large commercial and infrastructure projects where time efficiency and uniformity are essential. In the first half of 2025, Holcim reported that low-carbon ECOPact concrete sales rose to 31?percent of its ready-mix net sales, up from 25?percent in the prior-year period. Pre-cast components such as beams, panels, and modular blocks enable streamlined assembly, reduced waste, and better site management. This expansion of downstream value-added products strengthens the global cement market by diversifying revenue streams and meeting the demand for modern, industrialized construction solutions.

Market Segmentation & Regional Insights:

The cement market report typically segments the industry based on type, and end use. While segmentation varies across analysts, some common patterns define the global landscape.

By Type:

- Blended Cement: Blended cement combines Portland cement with supplementary materials such as fly ash, slag, or silica fume. This type offers improved durability, reduced carbon footprint, and better resistance to chemical attacks. It is widely used in large-scale infrastructure projects where sustainability and long-term performance are key considerations.

- Portland Cement: Portland cement is the most common cement type, used extensively in construction for buildings, roads, and bridges. It provides high strength, rapid setting, and reliable performance across diverse conditions. Its versatility and availability make it the preferred choice for general-purpose construction and large-scale civil engineering projects.

- Others: The Others category includes specialty cements such as rapid-hardening, expansive, oil-well, and white cement. These cements are designed for specific applications requiring unique properties, such as faster setting times, aesthetic finishes, or resistance to extreme conditions, catering to niche markets within the construction and industrial sectors.

By End-Use:

- Residential: Residential construction drives demand for cement in homes, apartments, and housing complexes. Cement is essential for foundations, walls, flooring, and roofing. Growing urbanization, rising population, and affordable housing initiatives contribute to steady demand from this segment, making it a key component of the cement market.

- Commercial: The commercial segment includes offices, retail spaces, hotels, and institutional buildings. Cement usage here focuses on structural integrity, durability, and architectural finishes. Expansion of business hubs, urban commercial development, and modern infrastructure projects support the growth of cement consumption in the commercial sector.

- Infrastructure: Infrastructure projects such as roads, bridges, airports, and railways are major drivers of cement demand. This segment requires large volumes of high-performance cement to ensure strength, longevity, and resilience. Government investments in public infrastructure and urban development initiatives continue to boost growth in this category.

Regional Insights:

Regional demand for cement is shaped by urbanization levels, industrial development, construction priorities, and government policy. Emerging regions experience rapid consumption due to expanding cities and infrastructure corridors. Advanced economies focus more on sustainable materials, renovation cycles, and technological innovation in manufacturing.

The world’s major construction regions collectively influence the world cement market, driving production strategies, supply chain models, and investment patterns for global manufacturers.

Forecast (2026-2034):

The future outlook for the cement industry is defined by steady demand growth, material innovation, and evolving construction needs. Analysts expect consistent expansion in the global cement market as nations upgrade infrastructure, expand urban centers, and invest in renewable energy installations requiring specialized cement formulations.

Global CAGR and Projected Market Value:

Forecasts point toward stable, long-term growth supported by modernization initiatives, industrial expansion, and the adoption of green materials. While projections vary by region and methodology, the underlying pattern indicates rising consumption across major markets.

Demand Drivers:

- Rapid urbanization and major infrastructure expansion: The continuing shift of populations into cities drives large-scale construction of roads, bridges, transit systems, and housing complexes. This transforms the cement market trends and reinforces cement’s role as the backbone of modern urban planning.

- Growing shift toward sustainable and eco-friendly cement: Low-carbon formulations and environmentally responsible production methods serve as a major catalyst for industry transformation. Green materials will remain central to the cement market analysis through the forecast period.

- Rising real-estate construction boosting cement demand: Residential and commercial construction will continue to be among the largest consumers of cement. Expanding business hubs, retail spaces, logistics parks, and institutional facilities contribute to steady market momentum.

- Expansion of ready-mix and pre-cast concrete supply chains: As modern methods of construction gain traction, the adoption of ready-mix concrete and modular building components will accelerate. These value-added segments expand opportunities for manufacturers and strengthen the cement market share of integrated suppliers.

Conclusion:

The cement industry stands at the intersection of economic development, sustainable construction, and industrial modernization. With rising urbanization, infrastructure upgrades, digital transformation, and the expansion of eco-friendly materials, the sector is poised for steady progress through the next decade. Manufacturers that embrace green processes, automation, and value-added downstream products will shape the future of the cement market trends and reinforce their competitive position.

For a deeper understanding of market dynamics, competitive landscapes, and future opportunities, businesses can explore or purchase the full study from IMARC. A comprehensive cement market report offers strategic guidance to navigate evolving industry challenges and capture emerging growth avenues.

Unlock Strategic Growth with IMARC: Your Trusted Partner in Cement Industry Intelligence

Choosing the right research partner is essential for navigating the complexities of the global cement market. IMARC Group delivers unmatched analytical depth, forward-looking insights, and business-focused intelligence designed to support confident decision-making in a rapidly evolving sector.

Choose IMARC Group as We Offer Unmatched Expertise and Core Services:

- Data-Driven Market Research: Our research blends expert forecasting with industry-grounded insights, offering clarity into shifting demand patterns, evolving material technologies, and competitive positioning.

- Strategic Growth Forecasting: IMARC delivers actionable outlooks that help companies anticipate future market conditions, emerging opportunities, and long-term investment priorities.

- Competitive Benchmarking: We analyze leading players, technological innovations, and operational models to help clients assess performance gaps and develop strategic advantages.

- Policy and Infrastructure Advisory: Our advisory services support stakeholders in understanding regulatory dynamics, sustainable construction policies, and infrastructure development strategies.

- Custom Reports and Consulting: IMARC offers tailored research solutions to address specific business challenges, regional assessments, or product-focused studies within the cement ecosystem.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)