Plastic Pyrolysis Cost Analysis: Cracking the Cost Curve

What is Plastic Pyrolysis?

Plastic pyrolysis is a form of recycling plastic waste via a process referred to as thermochemical recycling. This process produces liquid fuels, gases, and solid wastes through thermal degradation under low or no oxygen. Unlike traditional recycling, plastic pyrolysis involves the breakdown of long polymer chains into smaller hydrocarbon molecules using heat, in most cases in the presence of catalysts. The derived end-products, also termed pyrolysis oil, syngas, and char, can be used in place of conventional fuels or as raw materials in petrochemical industries. One of the greatest advantages of plastic pyrolysis is its ability to recycle mixed plastic wastes, which would not be feasible using traditional recycling methods.

Key Applications Across Industries:

Plastic pyrolysis processes have numerous uses that include energy recovery, petrochemical production of raw materials for manufacture of plastics, waste management, and projects promoted under the circular economy concept. Its most prominent application is the production of pyrolysis oil through the processing of plastic waste that is non-recyclable or of less value. The pyrolysis oil produced can serve as an alternate fuel source for industrial boiler plants, furnace components of industrial equipment, as well as for electric power production units. The pyrolysis oil can also be further processed to form diesel fuel oil.

A third major application is in petrochemicals, in which case the oil from pyrolysis is used for further refinement into plastics or fuel. In this application, chemical recycling is enabled, and plastics can be recycled into raw materials that are equivalent in quality to virgin plastics. In a typical pyrolysis reaction, gas is produced that does not condense at room temperature and can be recycled in a closed-loop system.

Plastic pyrolysis is also a significant process as far as integrated waste management is concerned. Cities and waste management companies employ plastic pyrolysis as a means of managing plastic waste that otherwise ends up in landfills or as a fuel component. The solid material produced can also be used as a construction material or processed based on quality and composition.

Besides, plastic pyrolysis can also be used for environmental clean-up and resource recovery in areas that do not have advanced plastic waste treatment infrastructure. It provides a financial motive for disposing and processing plastic waste when it can be recycled for new products.

What the Expert Says: Market Overview & Growth Drivers

The global plastic waste pyrolysis oil market reached a value of USD 673.5 Million in 2024. According to IMARC Group, the market is projected to reach USD 1,102.0 Million by 2033, at a projected CAGR of 5.6% during 2025-2033. Factors driving the global plastic pyrolysis market include the growing generation of plastics waste that cannot be recycled through mechanical means. The primary factor driving the plastic pyrolysis market is the increasing plastics waste that cannot be recycled through mechanical processes. Plastic pyrolysis is seen as the solution to the generation of plastics waste that cannot be recycled through mechanical means.

Government regulations and policies concerning environmental protection and the encouragement of a circular economy are major contributing factors for market growth. The encouragement of advanced recycling methods like chemical recycling by governments worldwide contributes largely towards this goal of a clean environment and a healthy climate. Plastic pyrolysis falls under this category of recycling methods as it generates reusable materials out of waste instead of disposing of them.

The increasing demand for alternative fuels and feedstocks accelerates the trend even further. The pyrolysis oil can be considered a partial substitute for fossil fuels and materials, thus contributing to a diversification of energy sources and assurance of resources. The push for a reduction in virgin fossil material use within various sectors creates a role for hydrocarbons produced through pyrolysis processes.

Commitments by corporate sustainability also matter significantly in this context. Many multinational brands and petrochemical firms have committed to the use of recycled materials and minimizing carbon footprints. Plastic pyrolysis makes it possible to have chemical recycling that complies with quality specifications even in food-grade plastics or industrial plastics, in cases where traditional mechanical recycling fails.

Technological advances enhance efficiency, quality, environmental friendliness, and commercial viability. Expenditure on system integration, development of better catalysts, and environmental mitigation is a boost to market confidence. Add to these, increased public concern, management requirements, and the need for a circular economy, and the resulting demand for the global production of plastic pyrolysis reactors is maintained.

Case Study on Cost Model of Plastic Pyrolysis Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale plastic pyrolysis plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed plastic pyrolysis plant in India. This plant is designed to pyrolyze 10,000 tons of plastic annually.

Pyrolysis Process: The manufacturing process of plastic pyrolysis is a thermochemical conversion technique designed to transform plastic waste into usable hydrocarbon products through controlled thermal decomposition. It offers an effective method for recovering energy and valuable materials from non-recyclable plastics, contributing to sustainable waste management and circular economy initiatives.

The process begins with feedstock collection and preparation, where post-consumer and post-industrial plastic waste is gathered and sorted to remove contaminants such as metals, glass, paper, and PVC. These materials can interfere with process stability or catalyst performance if not removed. The selected plastics, typically polyethylene (PE), polypropylene (PP), and polystyrene (PS) are then shredded into smaller, uniform pieces to enhance heat transfer during processing. The shredded feedstock is dried to eliminate moisture, ensuring consistent heating and preventing steam-related inefficiencies.

The prepared plastic feedstock is introduced into a pyrolysis reactor, which operates in an oxygen-free or low-oxygen environment to prevent combustion. The reactor is gradually heated to high temperatures, generally ranging from 350°C to 600°C, initiating the breakdown of long polymer chains into shorter hydrocarbon molecules. Depending on the reactor design, the process may be thermal pyrolysis (without catalysts) or catalytic pyrolysis, where catalysts are added to improve conversion efficiency, lower energy consumption, and control the composition of end products.

As the polymers decompose, they generate a mixture of hydrocarbon vapors, non-condensable gases, and solid residues (char). The hot vapor stream exits the reactor and passes through a condensation system, where it is cooled and converted into liquid pyrolysis oil. This oil is collected and may be filtered or lightly refined to remove impurities before being stored or sent for further upgrading into fuels or chemical feedstocks.

The non-condensable gases are separated and typically recycled within the process as a supplementary fuel to heat the reactor, significantly improving energy efficiency and process economics. The solid char or carbon residue that remains in the reactor is periodically removed and either disposed of safely or utilized for applications such as carbon black production or filler materials, depending on its composition and quality.

Throughout the process, key parameters like temperature, pressure, residence time, and gas composition are continuously monitored and controlled through automated systems to maintain operational stability and safety. Modern plastic pyrolysis plants are designed with advanced emission control systems and heat recovery units to minimize environmental impact while maximizing resource efficiency.

Overall, the plastic pyrolysis process provides a scalable and sustainable solution for converting plastic waste into valuable hydrocarbon products such as fuel oil, gas, and carbon residue, helping bridge the gap between waste management and renewable energy production.

Get a Tailored Feasibility Report for Your Project Request Sample

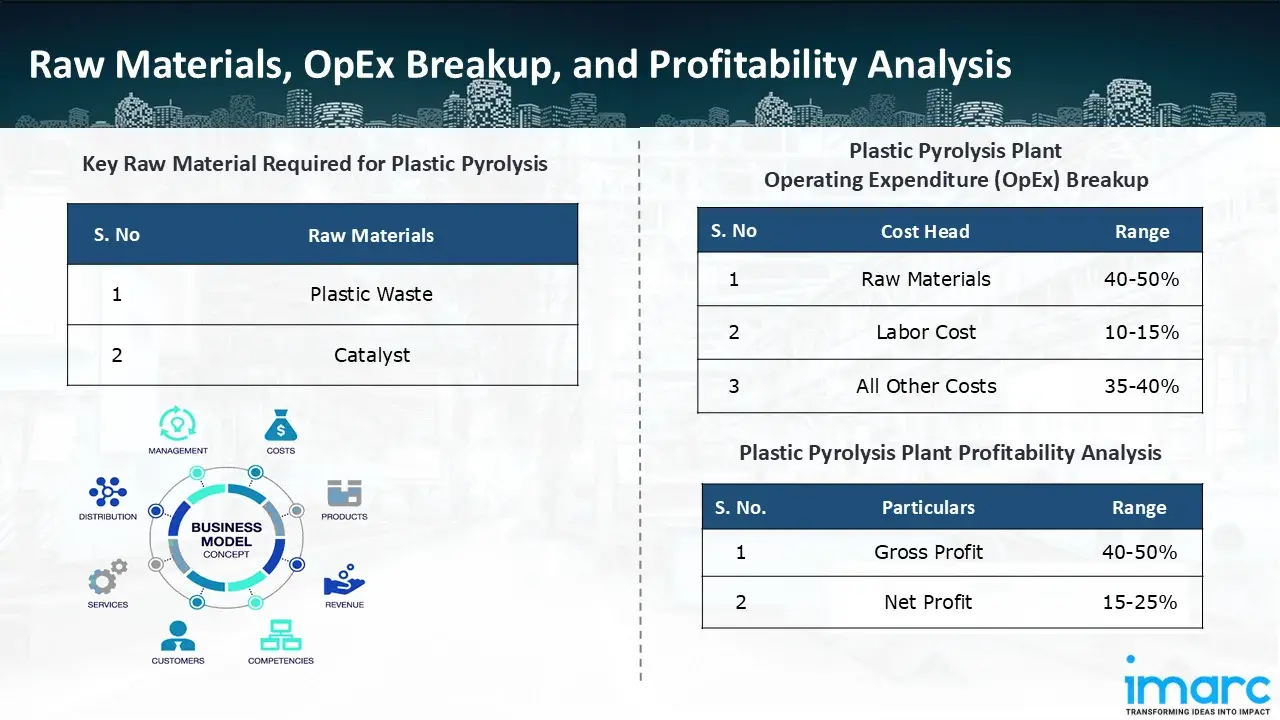

Raw Material Required:

The basic raw materials required for plastic pyrolysis include:

- Plastic Waste

- Catalyst

Machine Section or Lines Required:

- Shredder

- Reactor

- Condenser

- Distillation

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a pyrolysis plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a pyrolysis plant effectively. OpEx in a pyrolysis plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a pyrolysis plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in plastic pyrolysis plant ranges between 40-50%, labor cost ranges between 10% to 15%, and all other costs ranges between 35-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 40-50%, and net profit lie between the range of 15-25% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the plastic pyrolysis plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of pyrolyze 10,000 tons of plastic annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In March 2025, Lummus Technology, a global provider of process technologies and value-driven energy solutions, and Resynergi, a leading innovator in modular plastic recycling technology, announced the commercialization of Resynergi’s Continuous Microwave Assisted Pyrolysis (CMAP) Modules.

- In February 2025, Shell Chemicals Europe made a deal to purchase RES S.p.A.'s (RES) total pyrolysis oil production capacity. The plastic recycling plant in Pettoranello del Molise, one of the most sophisticated facilities in Europe, will create the oil. The facility will be able to produce 15,000 tonnes of pyrolysis oil annually and handle up to 20,000 tonnes of plastic waste.

- In December 2024, Vitol B.V. announced that it has reached a conditional agreement to purchase a majority stake in Waste Plastic Upcycling A/S. Vitol will own 90.36% of WPU's share capital upon completion, subject to a number of precedent-setting conditions.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104