Soya Chunks Manufacturing Cost Analysis: High Protein, High Focus Economics

_11zon.webp)

What are Soya Chunks?

Soya chunks are a protein-rich food item that is prepared using defatted soy flour, which is a by-product of soybean oil extraction. Soya chunks are prepared using the process of extrusion cooking, which converts the soy flour into porous, sponge-like granules with a fibrous structure that resembles meat when rehydrated. Soya chunks have a neutral flavor, which helps them absorb the flavors of spices and seasonings while cooking. Soya chunks are also nutritious due to their high protein content, essential amino acids, and low-fat content. Soya chunks are widely used as a protein source due to their shelf life, low cost, and versatility.

Key Applications Across Industries:

Soya chunks are mainly utilized as a meat substitute or protein extender in food applications. In home cooking, soya chunks are added to curries, stir-fries, pulao, biryani, gravies, and snacks, where they absorb flavors and have a chewy, meat-like texture. Their capacity to resemble minced meat makes them ideal for veggie preparations of cutlets, kebabs, burgers, meatballs, and fillings for wraps and rolls.

In institutional and mass-feeding programs, soya chunks are in great demand because of their high protein concentration, longer shelf life, and easy storage. They are often used in school meal programs, community kitchens, and food assistance programs to enhance protein consumption at a relatively low cost. Their fast hydration and easy cooking process make them ideal for mass food preparation.

Soya chunks are also utilized by the food processing industry as an ingredient in ready-to-eat foods, frozen foods, instant mixes, and dehydrated meal kits. In these products, they act as a texturizer and protein enhancer. In addition, they are also used as an ingredient in mixed foods, where they are used to partially substitute meat to lower the cost of formulation and yet maintain the protein content.

Apart from being directly consumed by human beings, textured soy products like soya chunks are also used in pet food and animal feeds as a protein source that is derived from plants.

What the Expert Says: Market Overview & Growth Drivers

The global soya chunks market reached a value of USD 2,079.17 Million in 2025. According to IMARC Group, the market is projected to reach USD 3,887.25 Million by 2034, at a projected CAGR of 7.2% during 2026-2034.

The global soya chunks market is fueled by the structural changes in food consumption and nutritional awareness. Among the most influential factors is the increasing need for accessible, high-quality protein sources, especially in developing and emerging countries. With the rising population and changes in eating habits, soya chunks are an economical way to fill the protein gap without resorting to animal protein sources.

The increasing popularity of vegetarian and plant-based diets is another significant factor. Consumers are increasingly turning away from meat due to ethical, environmental, and health reasons. Soya chunks are an excellent fit for this market as they are rich in protein, easy to prepare, and familiar to consumers in many cuisines, especially in Asia and Africa.

Urbanization and lifestyle changes are also propelling the market. With the increasing demand for convenient, non-perishable food products among urban consumers, soya chunks are an excellent fit due to their long shelf life, easy transportation, and low refrigeration needs.

Supply-side analysis: The presence of soybeans and the integration of soya chunks production with soybean oil production provide favorable manufacturing economics. As defatted soy flour is a by-product, it is most economical to convert it into value-added food products.

Government and institutional nutrition programs further strengthen demand. Programs aimed at enhancing protein intake, food security, and nutritional quality tend to favor plant protein sources because of their scalability and cost-effectiveness. Along with the growing global emphasis on sustainable food systems and lower environmental impact, these factors combined contribute to the steady global growth of soya chunks manufacturing.

Case Study on Cost Model of Soya Chunks Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale soya chunks manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed soya chunks manufacturing plant in India. This plant is designed to manufacture 5,000 tons of soya chunks annually.

Manufacturing Process: The production of soya chunks is a planned food processing activity that involves the production of a textured protein product with a meat-like structure from defatted soy flour. The production of soya chunks starts with soybean processing, where clean soybeans are removed from their hulls and crushed to extract oil. The extracted oil leaves a solid substance called soybean meal, which is further processed to remove any remaining fat, resulting in defatted soy flour. This defatted soy flour is the main raw material used in the production of soya chunks.

The defatted soy flour is first sieved and mixed to make it uniform in size and protein content. The flour is then processed using an extrusion cooking process, which is the main production step in the production of soya chunks. In the extruder, the flour is exposed to controlled heat, pressure, and mechanical shear force in the presence of water or steam. This process denatures the proteins in soy flour and restructures them into fibrous structures, giving soya chunks their characteristic porous and spongy texture.

As the material comes out of the extruder through shaped dies, it expands quickly because of the release of pressure and is cut into chunk-sized pieces. The hot, just-extruded chunks are then moved to a drying system, where the moisture is reduced to a constant level. It is essential that the drying process is done properly to ensure that the product has a long shelf life and does not develop any microbial growth.

After drying, the soya chunks are cooled and screened to separate the fines or broken pieces. Quality control checks are also done to determine the texture, moisture, protein, and appearance of the product. The final product is then packed in moisture-resistant packaging, either in bulk or retail packs, for distribution.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

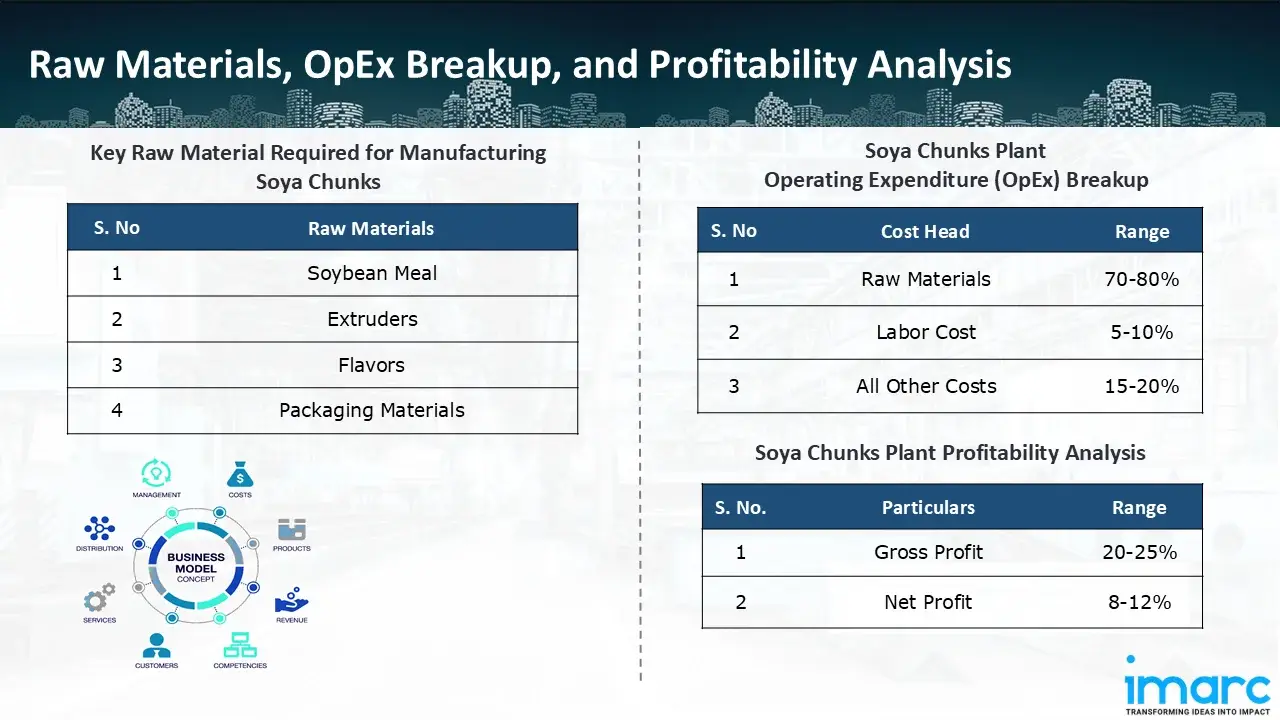

The basic raw materials required for soya chunks manufacturing include:

- Soybean Meal

- Extruders

- Flavors

- Packaging Materials

Machine Section or Lines Required:

- Extrusion

- Drying

- Flavoring

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in soya chunks manufacturing plant ranges between 70-80%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the soya chunks manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 5,000 tons of soya chunks annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In January 2026, The FMCG division of Sanjay Ghodawat Group, Ghodawat Consumer Limited (GCL), has announced the introduction of soya chunks under its STAR brand, a calculated move into the rapidly expanding plant-based protein market.

- In July 2025, ITC's flagship brand Aashirvaad announced expanding its presence in the plant-based protein market with the introduction of Aashirvaad Soya Chunks in Bihar and Jharkhand. The brand is now focussing on homemakers in these important Hindi heartland markets after a successful launch in West Bengal and Odisha.

- In January 2024, the FMCG manufacturer Adani Wilmar launched its new ‘Banao Kuchh Hatke’ marketing for their high-protein Fortune Soya Chunks brand. The 360-degree commercial encourages consumers to experiment with new and varied culinary possibilities by showcasing the versatility of soy chunks as an ingredient.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104