PVC Solvent Cement Manufacturing Cost Analysis: Strong Joints, Strong Returns

What is PVC Solvent Cement?

PVC solvent cement is a specialized adhesive formulation used to create permanent joints between polyvinyl chloride (PVC) pipes, fittings, and components. Unlike standard adhesives that rely on surface bonding, solvent cement chemically fuses PVC materials together. It works by using a blend of solvents and resins that temporarily soften and dissolve the surfaces of the PVC components. Once the solvent evaporates, the softened surfaces merge to form a strong, uniform joint that is essentially a molecular weld. Engineered to deliver pressure-tight and leak-resistant connections, PVC solvent cement is available in various viscosities and curing speeds to accommodate different pipe sizes, environmental conditions, and installation requirements. Its combination of strength, reliability, and ease of use makes it a critical material in plumbing, infrastructure, agriculture, and industrial piping systems worldwide.

Key Applications Across Industries:

PVC solvent cement plays a vital role in ensuring the structural integrity and performance of PVC piping systems across multiple sectors, including plumbing, construction, infrastructure, agriculture, and industry. In residential and commercial plumbing, it is primarily used for joining pipes and fittings that handle potable water, drainage, sewage, and wastewater. The resulting solvent-welded joints provide long-term leak resistance, ensuring reliable performance even under pressure and temperature variations.

For infrastructure projects, PVC solvent cement is essential in assembling underground piping networks for water distribution, stormwater drainage, and municipal sewage systems. These systems demand joints that can withstand soil movement, vibration, and fluctuating pressures over extended periods, which solvent-welded connections provide effectively.

In the agriculture sector, solvent cement is widely used to assemble irrigation systems, including drip and sprinkler systems, as well as water conveyance pipelines. These applications depend on strong, leak-proof joints that promote efficient water usage and minimal maintenance in demanding field environments.

Industrial uses include applications in chemical processing, water treatment plants, and manufacturing facilities where PVC piping carries acids, alkalis, or process fluids. The chemical compatibility of solvent cement ensures the integrity of these joints even under exposure to aggressive substances. It is also used in specialized installations such as swimming pool plumbing, aquaculture systems, and HVAC condensate lines.

In electrical and construction projects, PVC solvent cement is employed to bond conduits and fittings that protect and route electrical wiring. Its fast-curing, easy-to-apply nature allows for quick assembly and secure installation. Overall, the cement’s durability, strong bonding performance, and ease of use make it the preferred method for joining PVC components across a wide range of industries and applications.

What the Expert Says: Market Overview & Growth Drivers

The global PVC solvent cement market reached a value of USD 1.50 Billion in 2024. According to IMARC Group, the market is projected to reach USD 2.60 Billion by 2033, at a projected CAGR of 6.3% during 2025-2033. The global PVC solvent cement market continues to grow, driven primarily by increasing demand for PVC piping systems across construction, infrastructure, agriculture, and industrial sectors.

One of the strongest drivers is the expansion of water supply and sanitation infrastructure. As urbanization accelerates, particularly in developing regions, governments and private developers are investing heavily in water distribution and sewage treatment networks. Since solvent cement is indispensable for assembling PVC pipes in these systems, its demand rises in direct correlation with new construction and infrastructure projects.

Agricultural modernization is another significant factor fueling market growth. As farmers adopt advanced irrigation technologies to improve water efficiency and boost crop yields, the use of PVC pipes and solvent cement for assembly and repair becomes increasingly essential. Challenges such as water scarcity and climate change further encourage the use of efficient, durable, and easy-to-install piping solutions. In industrial sectors, the expansion of manufacturing, chemical processing, and water treatment facilities continues to boost demand for PVC piping systems. Solvent-welded joints provide reliable, corrosion-resistant, and cost-effective alternatives to metal piping in these environments, offering long-term savings in installation and maintenance.

The market also benefits from the practical and economic advantages of PVC solvent cement. It enables fast, tool-free installation, minimizing labor costs and project downtime—an important consideration for contractors and utilities. Furthermore, technological advancements such as low-VOC (volatile organic compound) and low-toxicity formulations are enhancing safety, improving environmental compliance, and opening new opportunities in regulated markets.

Additionally, global plumbing and construction standards continue to recognize solvent-welded joints as dependable and safe, further reinforcing their use in both public and private projects. Overall, as PVC pipes remain the material of choice for modern fluid transport systems, the demand for PVC solvent cement is set to grow steadily due to infrastructure investment, agricultural development, industrial expansion, and sustainability-focused innovation.

Case Study on Cost Model of PVC Solvent Cement Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale PVC solvent cement manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed PVC solvent cement manufacturing plant in India. This plant is designed to manufacture 1,000 kilo litre of PVC solvent cement annually.

Manufacturing Process: The manufacturing of PVC solvent cement involves a carefully controlled series of operations including formulation, blending, filtration, and packaging, designed to produce a consistent, high-performance bonding compound suitable for PVC piping applications. Production begins with the selection of raw materials, which include PVC resin and a blend of solvents such as tetrahydrofuran (THF), methyl ethyl ketone (MEK), and cyclohexanone, among others. The exact solvent composition depends on regulatory compliance, performance requirements, and the intended application. In this formulation, the PVC resin acts as the bonding component, while the solvents serve to dissolve and soften the PVC pipe and fitting surfaces during application, allowing them to chemically fuse when joined.

During the mixing stage, pre-measured quantities of solvents are loaded into stainless steel mixing vessels equipped with agitation and temperature control systems. The PVC resin is then gradually introduced under controlled conditions to ensure uniform dispersion and to prevent the formation of lumps. Mixing continues until a smooth, homogeneous solution with the desired viscosity is achieved. Viscosity control is essential, as solvent cements are produced in various grades—regular-bodied, medium-bodied, and heavy-bodied, to match different pipe sizes, pressure ratings, and installation conditions. At this stage, stabilizers, thickeners, and performance additives may be incorporated to enhance the product’s shelf life, bonding strength, and application performance.

Once the blending process is complete, the solvent cement undergoes filtration to remove any undissolved particles or impurities, ensuring smooth application and consistent bonding results. The filtered product then proceeds to quality-control testing, where parameters such as viscosity, solids content, setting time, and bonding strength are verified according to relevant industry standards and specifications. After approval, the cement is transferred to automated filling lines, where it is packaged into sealed metal cans or plastic containers to prevent solvent evaporation. Packaging operations include accurate labeling with safety instructions, batch details, hazard symbols, and regulatory information to ensure traceability and compliance.

Throughout the manufacturing process, strict safety, ventilation, and environmental control measures are maintained due to the volatile and flammable nature of solvents. Modern production facilities emphasize formulation precision, process automation, and adherence to occupational and environmental regulations to ensure both product quality and worker safety. The result is a reliable, high-quality solvent cement that provides durable, leak-resistant joints for PVC piping systems used across plumbing, industrial, agricultural, and infrastructure applications.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

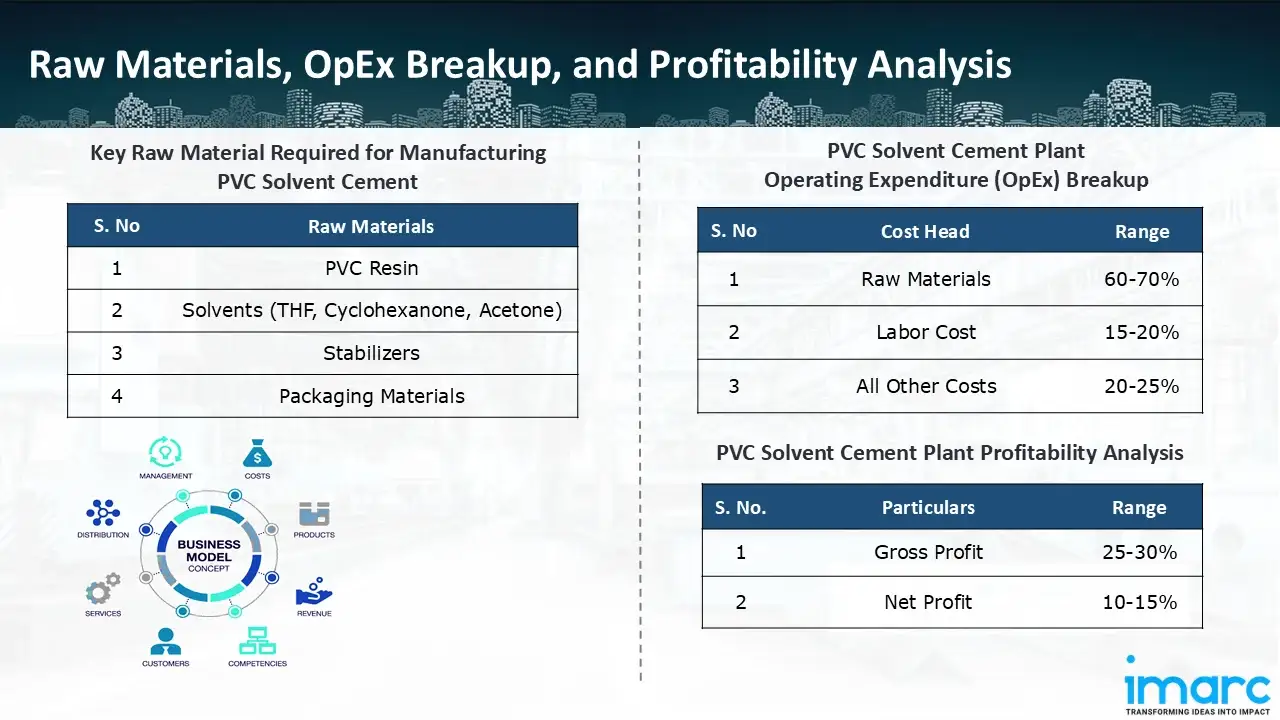

The basic raw materials required for PVC solvent cement manufacturing include:

- PVC Resin

- Solvents (THF, Cyclohexanone, Acetone)

- Stabilizers

- Packaging Materials

Machine Section or Lines Required:

- Mixing

- Grinding

- Dissolving

- Filtering

- Filling

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in PVC solvent cement manufacturing plant ranges between 60-70%, labor cost ranges between 15% to 20%, and all other costs ranges between 20-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-30%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the PVC solvent cement manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1,000 kilo litre of PVC solvent cement annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, Qatar Vinyl Company announced its plans to open the nation's first PVC plant in Mesaieed, with a 350,000-ton annual capacity.

- In May 2024, The Woodlands, Texas-based Weld-On® announced that E-Z Weld has been acquired. E-Z Weld exports products like cement to over 50 countries in the thriving Latin America, Caribbean, Middle East, Africa, Asia, and European markets.

- In February 2024, Chemplast Sanmar of India commenced commercial production at its new 41,000 tonne/year speciality paste polyvinyl chloride (PVC) resin facility located in Cuddalore, in the southern state of Tamil Nadu. The company's paste PVC capacity has expanded to 107,000 tonnes/year thanks to the new plant, which was established at a cost of Rs 3.6 billion (US$ 43 million).

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104