Soya Milk Manufacturing Cost Analysis: Liquid Protein, Solid Margins

_11zon.webp)

What is Soya Milk?

Soy milk is a plant-based beverage made from whole soybeans that have been soaked, ground, and their liquid extracted, then cooked and filtered. It is completely devoid of elements originating from animals and is intended to operate and look like dairy milk. In addition to naturally existing proteins, carbs, and healthy fats from soybeans, soy milk is frequently supplemented with vitamins and minerals to improve its nutritional value. Its flavor is neutral and mild, though it might change based on formulation and processing. Because of its nutritional profile, adaptability, and suitability for vegan and lactose-intolerant consumers, soy milk is a popular dairy substitute.

Key Applications Across Industries:

Soya milk is mainly utilized as a direct drink, either plain or flavored as a healthy substitute for dairy milk. It is widely used in breakfast diets, along with cereals, oats, or granola, and as a mixture for smoothies and shakes. Its high protein levels, relatively speaking, compared to other plant-based milks, make it especially attractive to health-conscious consumers.

In the kitchen, soya milk is widely used as a cooking ingredient. It serves as a substitute for dairy milk in various recipes such as sauces, soups, curries, pancakes, cakes, and bread. Its stable protein structure makes it an ideal ingredient for use in hot drinks such as tea and coffee. In traditional cooking, especially in Asia, hot soya milk is commonly served and used in desserts and snacks.

The food processing industry utilizes soya milk as a raw material for the production of value-added products such as flavored drinks, fermented drinks, yogurt substitutes, ice creams, tofu, and other soy products. In institutional food services, soya milk is commonly used as part of a balanced meal, especially in areas where dairy products are not commonly consumed.

Furthermore, vegan, lactose-free, and cholesterol-conscious diets are among the health-conscious and specialized diets that include soy milk. Its versatility in beverages, cooking, and processed goods demonstrates its wide range of applications in both domestic and commercial settings.

What the Expert Says: Market Overview & Growth Drivers

The global soya milk market reached a value of USD 5.79 Billion in 2025. According to IMARC Group, the market is projected to reach USD 9.08 Billion by 2034, at a projected CAGR of 5.1% during 2026-2034.

The soya milk market is driven by the long-term shift in consumer preference towards plant-based and alternative sources of nutrition. The most important driving factor for the soya milk market is the rising awareness about lactose intolerance and dairy sensitivity, which pushes consumers to look for alternative sources of milk that can be consumed without any digestive issues. Soya milk, being one of the oldest and most established sources of plant-based milk, has the advantage of familiarity and acceptance.

Health and nutritional factors also form an important part of the equation. Soya milk is considered a nutritionally strong source of plant-based milk because of its high protein content and functional properties. Consumers who are health and nutrition-conscious and are reducing their saturated fat intake tend to include soya milk in their daily diet. Its use as a vegan and vegetarian food source further widens its consumer base.

Another key factor is environmental and sustainability issues. As the environmental impact of animal farming becomes more widely understood, consumers and organizations turn to plant-based drinks as part of a more sustainable lifestyle. Soya milk is an integral part of this shift, thanks to existing supply chains for soybeans and the ability to easily scale up production.

Urbanization and lifestyle trends also contribute to market expansion. The packaged, stable, and ready-to-drink format of soya milk products meets the requirements of urban consumers, who are looking for convenience and longer product shelf life. Improved access to products through modern retail and online shopping channels also supports market growth.

From a market standpoint, improvements in processing technology have increased the taste, texture, and shelf life of soya milk, overcoming previous taste-related hurdles. Along with product line extension and the availability of raw materials, these factors together contribute to the global soya milk manufacturing market.

Case Study on Cost Model of Soya Milk Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale soya milk manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed soya milk manufacturing plant in India. This plant is designed to manufacture 2 million liters of soya milk annually.

Manufacturing Process: The production process of soya milk is a regulated food processing activity aimed at extracting nutrients from soybeans, producing a smooth, stable, and drinkable fluid. The process starts with raw soybean selection and cleaning, where high-quality soybeans are screened to eliminate contaminants such as stones, dust, and defective soybeans. The cleaned soybeans are then soaked in water for a few hours to rehydrate them, soften their texture, and decrease anti-nutritional compounds.

The soaked soybeans are then washed and wet ground with water to produce a fine slurry. This grinding process breaks down the soybean cells, releasing proteins, lipids, and soluble carbohydrates into the liquid phase. The slurry is then filtered or separated, usually using centrifugal separators or filters, to separate the insoluble fiber residue called okara. The filtered liquid is raw soya milk.

The extracted soya milk is then heat-treated or cooked to inactivate enzymes, remove unwanted flavors, and ensure microbiological safety. Heat treatment also enhances protein functionality and flavor stability. After heat treatment, the milk is homogenized to distribute fat and protein particles evenly, creating a smooth texture.

At this point, formulation changes are implemented. Sweeteners, flavors, stabilizers, and micronutrients such as calcium and vitamins can be added based on the product specification. The final product is then pasteurized or sterilized through processes like UHT treatment to ensure the desired shelf life.

The final soya milk product is aseptically packaged in bottles, cartons, or pouches for distribution. Quality control is implemented to ensure quality, safety, and acceptability of the product before it is put into the market.

Get a Tailored Feasibility Report for Your Project Request Sample

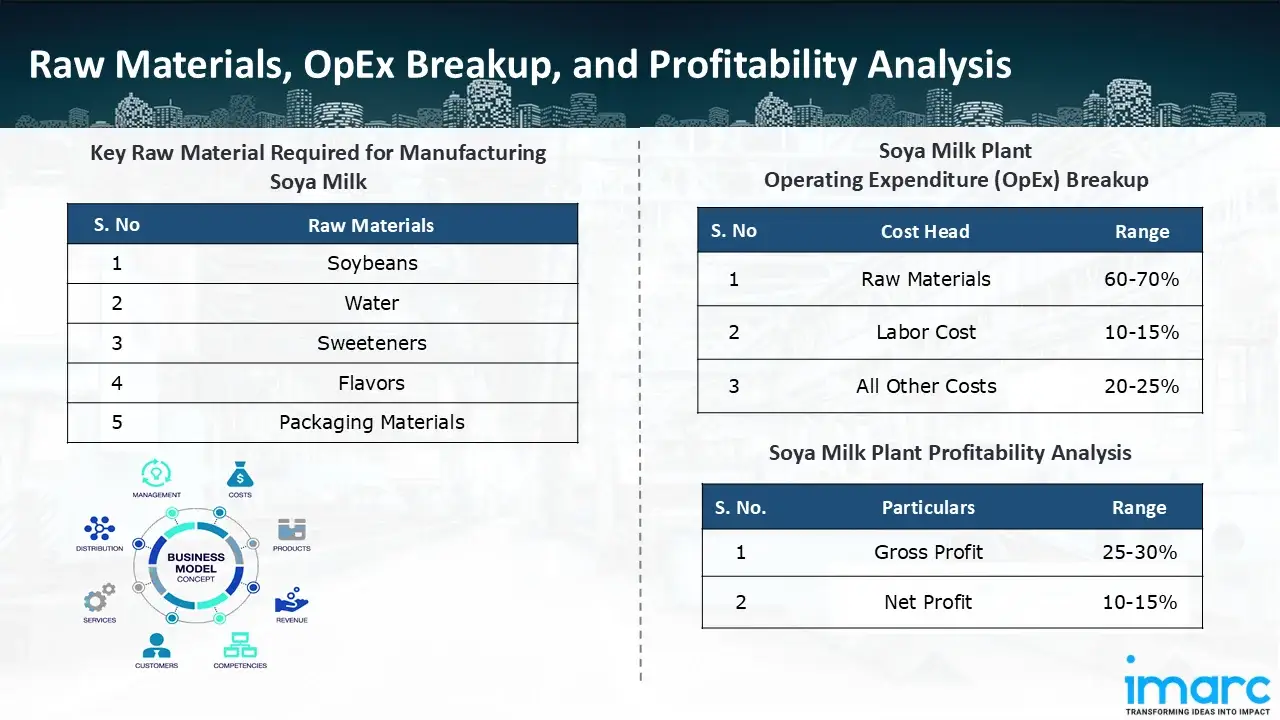

Raw Material Required:

The basic raw materials required for soya milk manufacturing include:

- Soybeans

- Water

- Sweeteners

- Flavors

- Packaging Materials

Machine Section or Lines Required:

- Cleaning

- Soaking

- Grinding

- Filtering

- Homogenization

- Pasteurization

- Filling

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in soya milk manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-30%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the soya milk manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2 million litres of soya milk annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In January 2026, Califia Farms, a well-known, high-end, plant-based beverage brand, announced the launch of Simple & Organic Soymilk under its best-selling Simple & Organic platform. Two new Simple & Organic creamer flavors, Sweet Crème and Salted Caramel, as well as updated core creamer recipes and brand-new Cold Brew and Matcha blends with Almondmilk would be making their debut with Califia's inaugural Soymilk.

- In September 2025, ITC's flagship brand Aashirvaad announced expanding its presence in the plant-based protein market with the introduction of Aashirvaad Soya Milk in Bihar and Jharkhand. The brand is now focussing on homemakers in these important Hindi heartland markets after a successful launch in West Bengal and Odisha.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104