Tea Processing Cost Analysis: Harvested Leaves, Measured Margins

_11zon.webp)

What is Tea?

Tea is a drink made from the processed leaves and flower buds of the plant Camellia sinensis. The essential properties of tea, namely flavor, aroma, color, and strength, depend on the level of oxidation, drying, and fermentation of the processed leaves. Tea can be categorized based on the processing techniques into black tea, green tea, oolong tea, white tea, and specialty teas. Tea has natural ingredients such as caffeine, polyphenols, and amino acids, which impart its taste and properties. Tea is one of the most popular drinks in the world because of its cultural and versatile nature.

Key Applications Across Industries:

Tea is mainly used as a beverage, hot or cold, and is an essential part of many cultures. Black tea is normally taken with milk or sugar, while green and white teas are normally taken without any additives to preserve their taste. Iced tea and flavored teas have increased the popularity of tea among the younger generation.

Tea is also used as an ingredient in the food and beverage industry. Tea extracts and tea concentrates are used in bottled drinks, functional drinks, kombucha, confectionery, bakery products, ice cream, and desserts. Matcha tea and other powdered teas are used in the culinary industry for flavoring, coloring, and nutritional purposes.

Tea is also used in health and wellness products. Tea extracts are used in dietary supplements, nutraceuticals, and herbal mixes due to their natural bioactive compounds. Tea extracts are also used in the cosmetics industry for skincare and haircare products due to their antioxidant and soothing properties.

Moreover, tea is also associated with hospitality, gifting, and the premium lifestyle segment, where specialty, artisanal, and single-origin teas are marketed as premium products. The various consumption patterns and downstream applications of tea emphasize its versatility as a product that goes beyond the traditional beverage category.

What the Expert Says: Market Overview & Growth Drivers

The global tea market reached a value of USD 26.7 Billion in 2025. According to IMARC Group, the market is projected to reach USD 39.4 Billion by 2034, at a projected CAGR of 4.40% during 2026-2034.

The global tea market is fueled by a set of cultural, economic, and lifestyle factors. One of the most prominent drivers of the tea market is its deeply ingrained cultural associations in the principal consuming nations. In many nations, tea drinking is a deeply ingrained habit and a part of social culture, thereby ensuring a steady base of demand across generations.

Health consciousness is another significant driver that is influencing the consumption of tea in contemporary times. Consumers are increasingly linking tea with natural wellness, hydration, and a healthy lifestyle. This has helped drive demand for green tea, herbal teas, and specialty teas that are perceived as a healthier or more functional alternative to sweet drinks. The trend towards natural and minimally processed beverages further underlines the relevance of tea.

Urbanization and consumption patterns are also adding to the growth of the market. As the pace of urban living accelerates, there is a growing demand for convenient packaging such as tea bags, instant tea, and ready-to-drink tea. These packaging options open up consumption occasions beyond the home, such as offices, travel, and on-the-go consumption.

Premiumization is also a rapidly emerging trend in the developed as well as the emerging markets. Consumers are increasingly showing interest in origin-specific teas, artisanal processing, organic farming, and specialty blends. This trend gives the tea processing industry the opportunity to create differentiated products with added value.

On the supply side, tea processing provides employment opportunities in rural areas, thus encouraging continued growth in tea production areas. Along with the growing global trade and changing consumer behavior, these structural drivers are cumulatively contributing to the steady growth of the global tea processing and consumption market.

Case Study on Cost Model of Tea Processing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale tea processing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed tea processing plant in India. This plant is designed to process 1,000 MT of tea annually.

Processing Flow: The tea manufacturing process entails a number of steps that are carefully followed to ensure the production of tea with desired flavor, aroma, and appearance. The process starts with plucking, where the leaves and buds of the tea plant are carefully selected. The leaves are immediately processed to prevent deterioration.

The first step in tea manufacturing is withering, where the plucked leaves are laid out in troughs or racks and subjected to controlled airflow. This process reduces the moisture content of the leaves and makes them pliable for processing. The next step is rolling, where the withered leaves are rolled or twisted using machines to break the cell walls. This process releases oils and enzymes in the leaves, which trigger a chemical reaction that affects the flavor.

In the case of black and oolong tea, the rolled leaves are oxidized, which is also called fermentation. During this process, enzymatic reactions take place as the leaves come into contact with oxygen, which gives the tea its characteristic color, flavor, and aroma. The process of oxidation is carefully controlled to ensure that the desired tea quality is obtained. This process is either avoided or minimized in the case of green and white tea.

The next step in the process is firing or drying the leaves using hot air or any other heat source to stop the enzymatic reactions and reduce the moisture content of the tea to safe levels for storage. The dried tea is then sorted according to its size and appearance. The final steps include blending, packaging, and quality checking.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

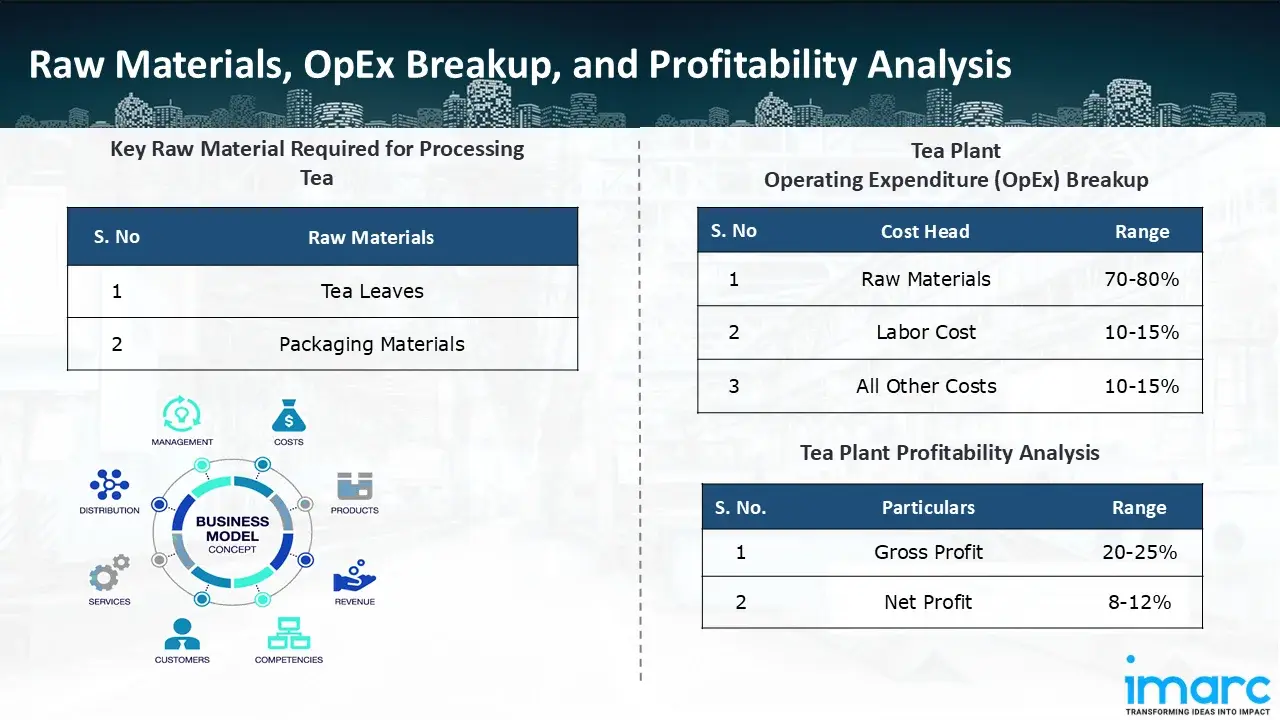

The basic raw materials required for tea processing include:

- Tea Leaves

- Packaging Materials

Machine Section or Lines Required:

- Withering

- Rolling

- Fermentation

- Drying

- Sorting

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a processing plant effectively. OpEx in a processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in tea processing plant ranges between 70-80%, labor cost ranges between 10% to 15%, and all other costs ranges between 10-15% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the tea processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, processing, capital expenditure, and operational expenses. By addressing the specific requirements of processing 1,000 MT of tea annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale processing ventures.

Latest News and Developments:

- In August 2025, the renowned British tea company Twinings announced the release of Twinings Refreshers, its first-ever herbal tea instant beverage designed to dissolve in cold water and offer a potent flavour in a matter of seconds. Twinings Refreshers offers a novel perspective on herbal tea, especially for Gen Z and Millennial consumers, and was developed to satisfy the growing need for cool, functional drinks.

- In February 2024, the Tamil Nadu government's decision in its 2024–2025 Budget giving 9 crore to protect their livelihood has been warmly received by small tea producers in the Nilgiris. Members of the 16 industrial co-operative (Indco) tea enterprises that supplied green leaf tea the previous year will receive an incentive of two per kilogram from the allotment. The announcement will help about 27,000 small-scale tea growers.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the processing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish processing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104